Automatic battery replacing equipment for end part of truck and method of automatic battery replacing equipment

A power exchange equipment and automatic technology, applied in vehicle components, charging stations, electric vehicles, etc., can solve the problems of low degree of automation and low power exchange efficiency, and achieve the effect of reducing operating costs and improving power exchange efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

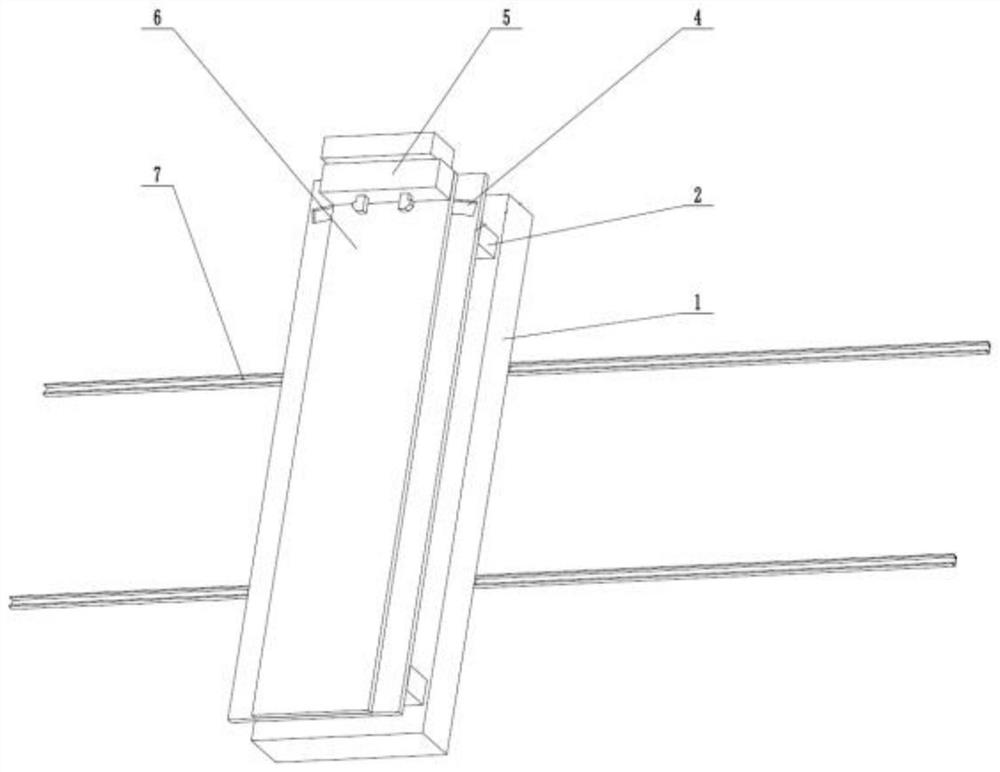

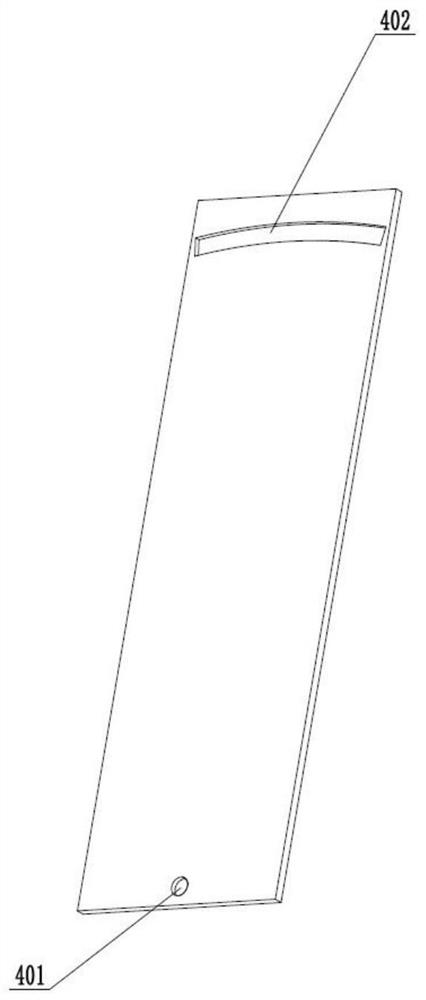

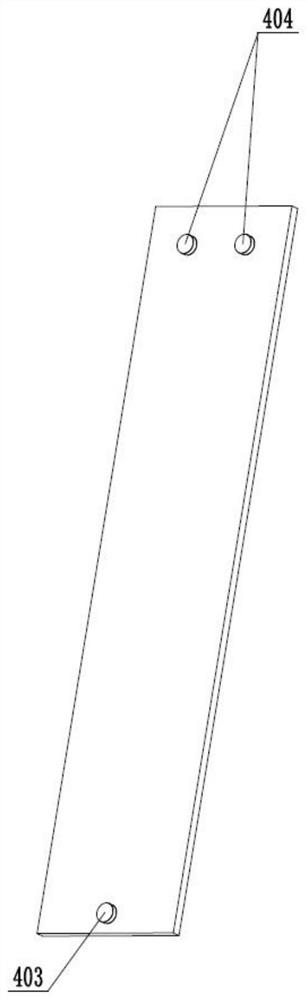

[0027] see figure 1 As shown, the present invention is an automatic power exchange device for the end of a truck, comprising a bottom base 1, a lifting device 2, a rotating base 4, a dragging device 5 and a power exchange platform 6, and the bottom surface of the bottom base 1 is fixed The first electric wheel is installed; the power exchange platform 6 is used to place the power battery on the truck; between the power exchange platform 6 and the bottom base 1, a lifting device 2 and a rotating seat 4 are sequentially installed; the lifting device 2 and the rotating seat 4. Control the lifting height and rotation angle of the power-changing platform 6 respectively; the dragging device 5 is fixedly installed on the power-changing platform 6, and the dragging device 5 is used to cooperate with the dragging hole on the power battery, and remove the power battery. Drag down to the power exchange platform 6.

[0028] Among them, the first electric wheel adopts electric guide wheel...

Embodiment 2

[0053] see Figure 1-6 As shown, the present invention is an automatic power exchange device for the end of a truck, which is different from the first embodiment in that:

[0054] Also includes buried track 7, and the first electric wheel adopts electric guide wheel;

[0055] The buried track 7 is slidingly matched with the first electric wheel, and the automatic power exchange device is moved to the position for power exchange through the buried track 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com