Electric car battery replacement visual system and calibration method thereof, and battery location method

A technology for electric vehicles and vision systems, applied in image data processing, instrumentation, computing, etc., can solve the problems of relying on battery consistency, battery size and self-weight, and high requirements for battery replacement fixtures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] The invention provides a vision system, a calibration method and a battery positioning method for battery replacement of electric vehicles to meet the problem of compatibility of batteries from different manufacturers in the battery replacement process.

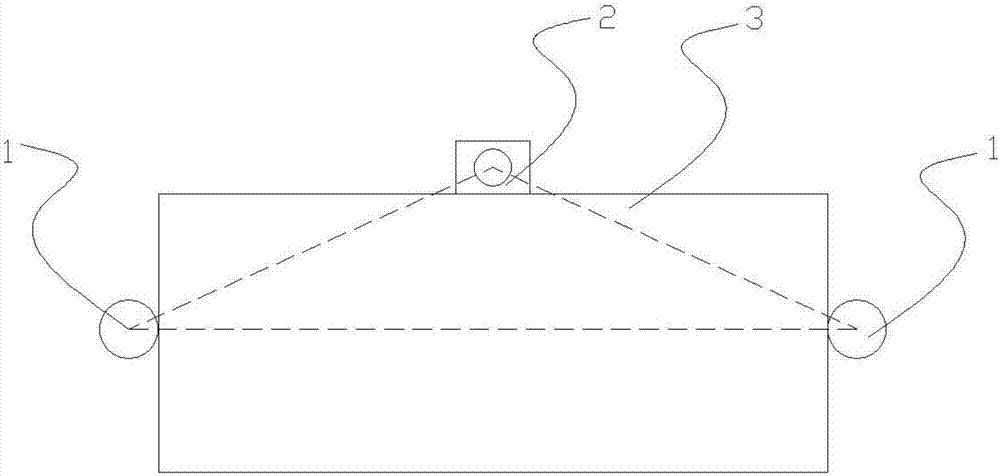

[0081] First of all, the vision system for battery replacement of electric vehicles of the present invention is now described, see figure 1 with figure 2 , the system includes a laser sensor 1 and an industrial camera 2; there are two laser sensors 1 and they are installed side by side on both sides of the battery replacement fixture 3, and the distance between the two laser sensors 1 is G; the industrial camera 2 is installed on the battery replacement fixture 3 The electric fixture 3 is located between the two laser sensors 1; the connection between the industrial camera 2 and the two laser sensors 1 forms an isosceles triangle.

[0082] Based on the above description of the vision system, there are certain errors ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com