Impurity filtering device for water treatment agent production

A technology of impurity filtration and water treatment agent, applied in the field of water treatment, which can solve the problems of unfavorable impurity filtration and achieve the effect of promoting filtration and preventing accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

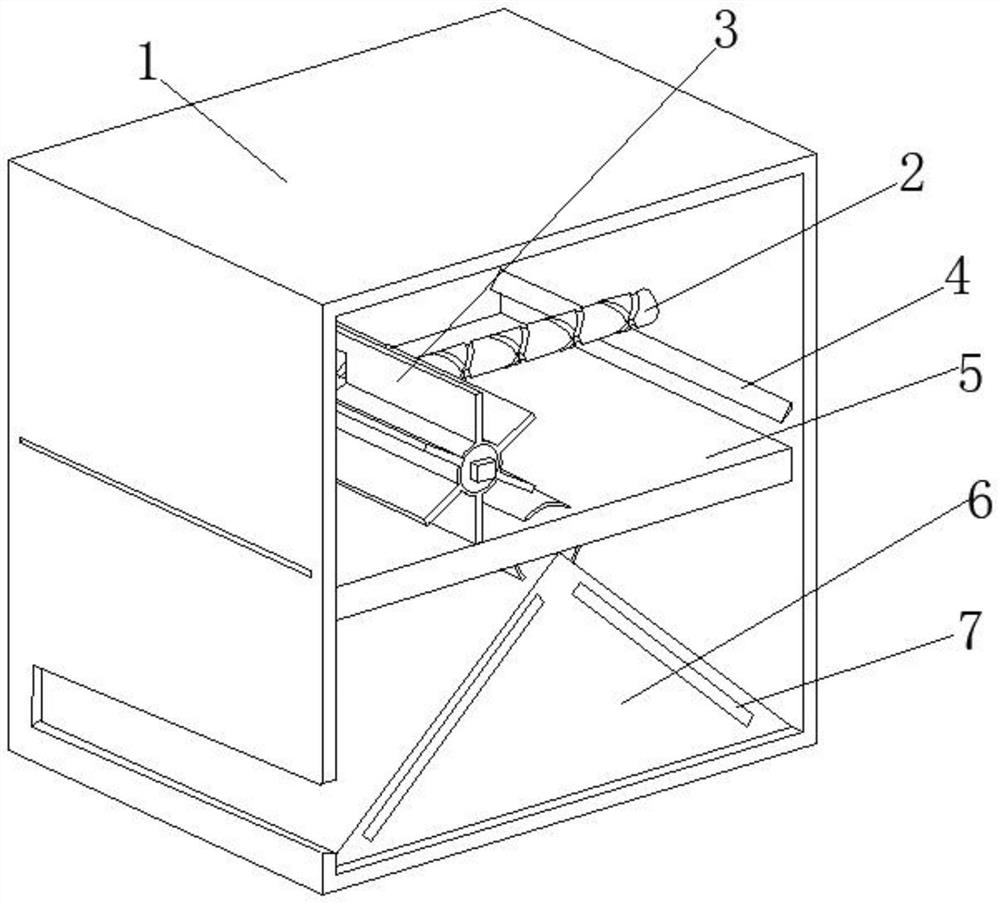

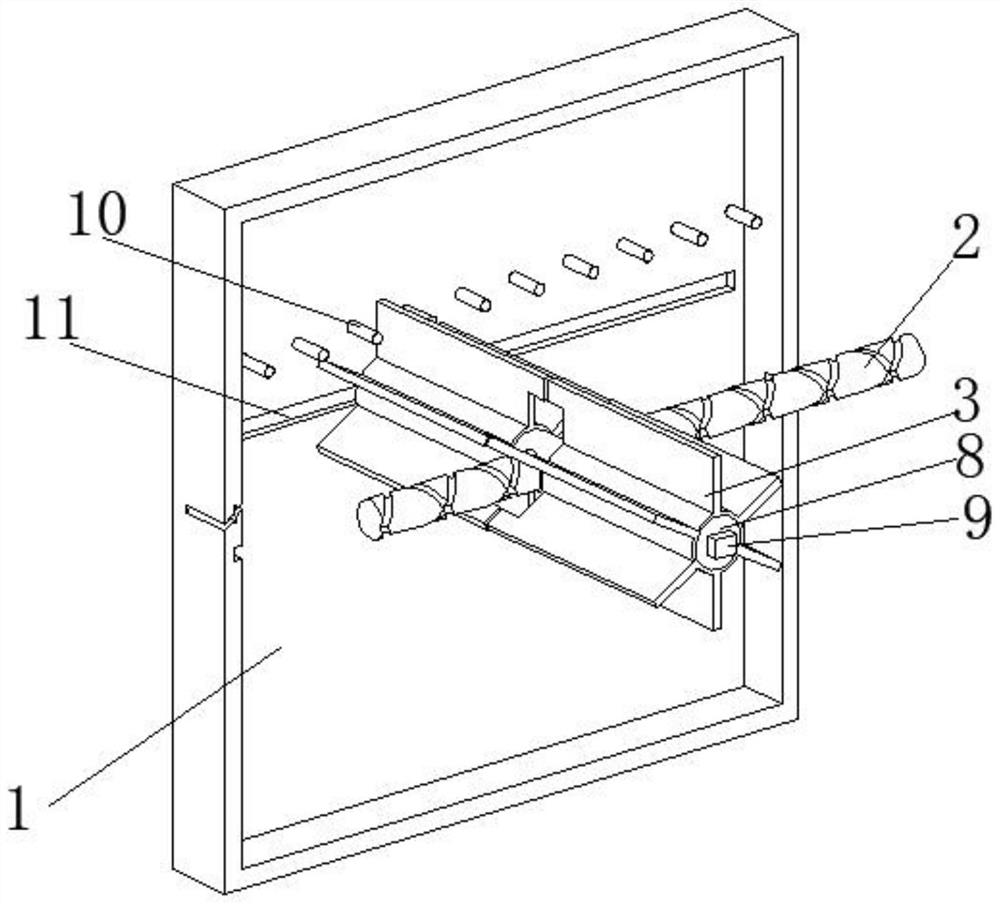

[0029] A kind of impurity filtering device for water treatment agent production, such as Figure 1-Figure 6 As shown, it includes a box body 1, the inner wall of the box body 1 is rotatably connected with a screw rod 2, the surface of the screw rod 2 is movably connected with a transmission rod 8, and both ends of the transmission rod 8 are fixedly connected with a slider 9, The surface is rotatably connected with the impeller 3, the inner walls of the front and rear sides of the box body 1 are fixedly connected with a number of clamping rods 10, and the inner walls of the front and rear sides of the box body 1 are provided with chute 11. The filter plate 5 filters the impurities so that the impurities inside are blocked. At the same time, the screw rod 2 is rotated by setting the motor. The screw rod 2 will drive the transmission rod 8 to reciprocate left and right through the cross-shaped spiral groove on the surface and the block on the inner wall of the transmission rod 8. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com