Wiring platform

A platform and wiring technology, applied in workbenches, manufacturing tools, etc., can solve the problems of rising product processing costs, reducing product production costs, and high requirements for operators and maintenance personnel, and achieves the effect of improving efficiency and strong applicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

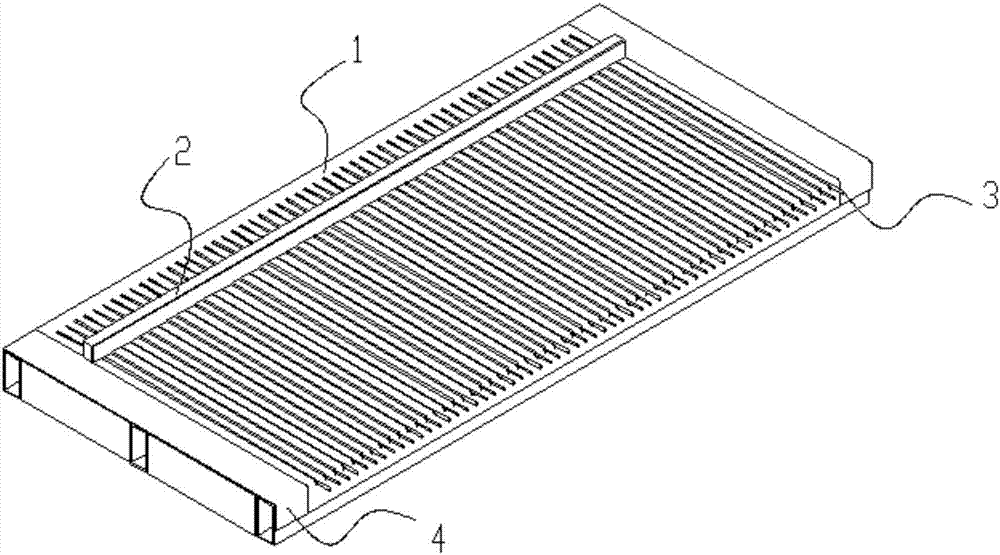

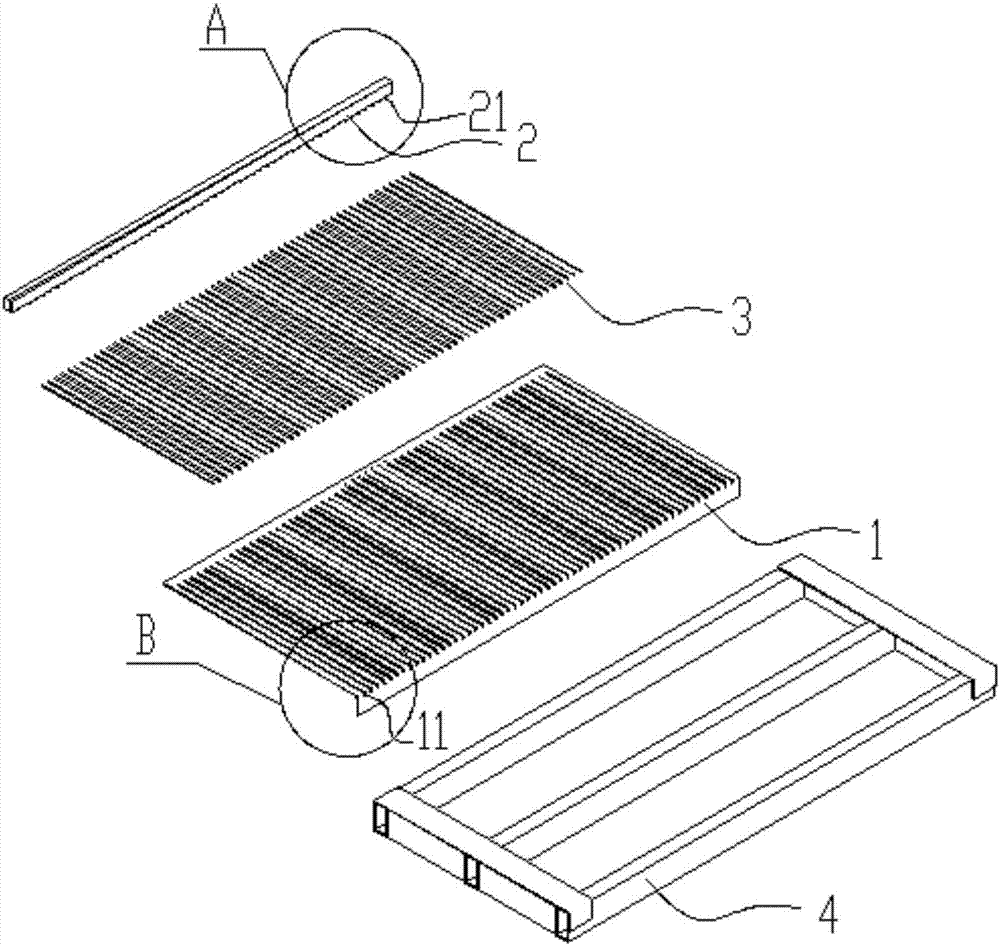

[0036] Embodiment 1: A wiring platform that can independently realize the function of manual swinging, such as Figure 1-3 with Figure 7-8 As shown, it includes a swinging material platform 1 and a width adjustment bar 2. The upper surface of the swinging material platform 1 has a number of wire grooves 11 for placing material rods 3, and each of the wire grooves 11 is along the The width direction of the platform 1 is set, and all the wire slots 11 are arranged at intervals along the length direction of the swing material platform 1 and arranged in parallel, each of the wire slots 11 can only accommodate one material rod 3, so The width adjusting bar 2 is arranged along the length direction of the swing material platform 1 and can be moved and positioned along the width direction of the swing material platform 1, and one end of the material rod 3 after falling into the wire groove 11 stretches out of the Place material platform 1 outside.

[0037]The width adjustment bar 2...

Embodiment 2

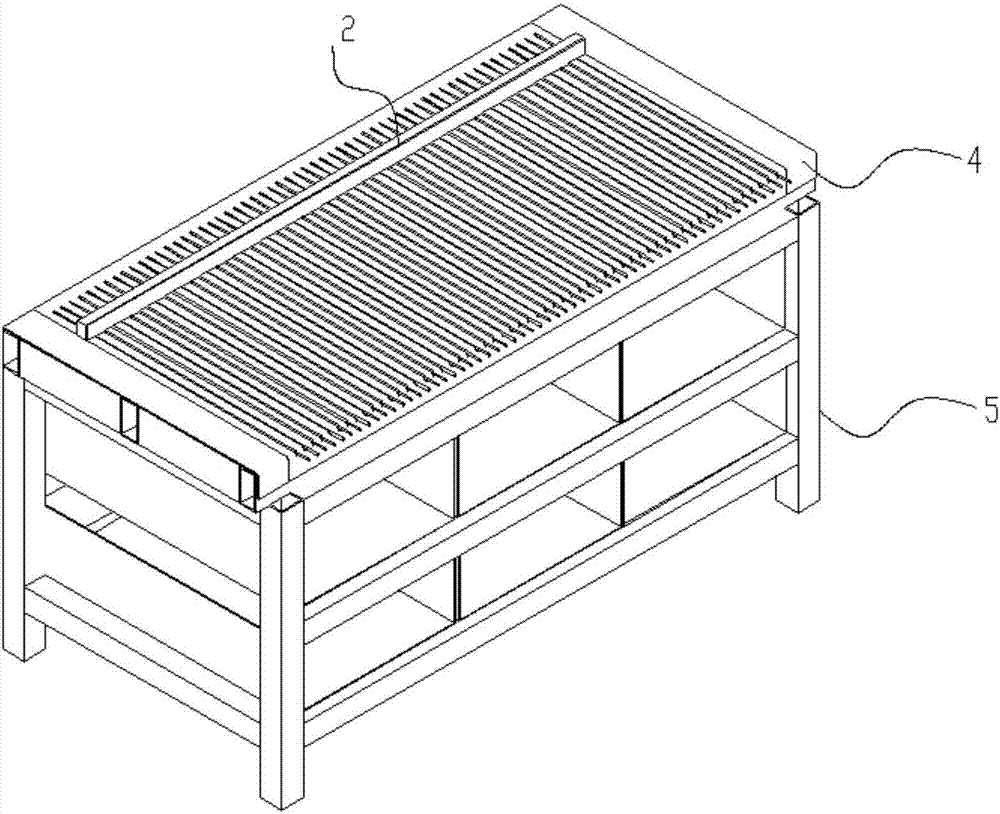

[0044] Embodiment 2: an automatic wiring platform, such as Figure 4-6 As shown, the material swing function can be automatically realized, and it has the wiring platform described in Embodiment 1, and is also provided with a pushing mechanism, and the pushing mechanism is connected with a power device, and the pushing mechanism has a 1 above and close to the pusher 6 on the upper surface of the swing platform 1, the power device can drive the pusher 6 along the length direction of the swing platform 1 and close to the upper surface of the swing platform 1 The surface moves.

[0045] Preferably, in this embodiment, the distance between the bottom end of the pushing member 6 and the upper surface of the swing platform 1 is smaller than the diameter of the material rod 3 .

[0046] The pushing mechanism also includes a chute moving bracket 7 and a guide rail 8, the guide rail 8 is arranged along the length direction of the swing material platform 1 and is located on both sides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com