Regeneration control method and device of particulate matter trap, medium, equipment and vehicle

A particle trap and regeneration control technology, applied in the field of vehicles, can solve the problems of particle trap clogging, burning, accelerated carbon accumulation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The specific embodiments of the present disclosure will be described in detail below with reference to the accompanying drawings. It should be understood that the specific embodiments described herein are only used to illustrate and explain the present disclosure, but not to limit the present disclosure.

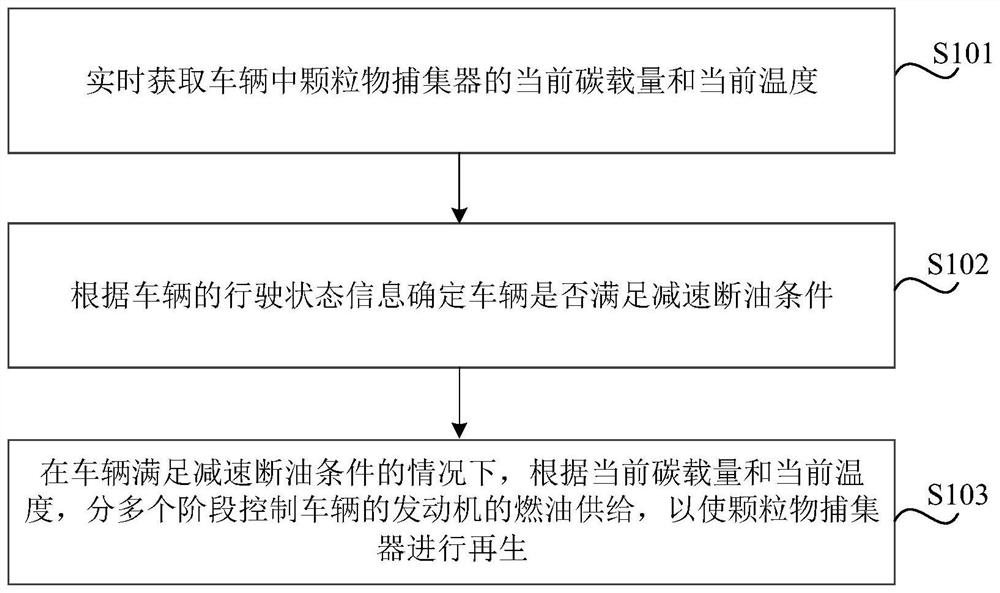

[0043] figure 1 is a flow chart of a regeneration control method of a particulate filter according to an exemplary embodiment, and the method can be applied to a controller in a vehicle, such as figure 1 As shown, the method may include S101 to S103.

[0044] In S101, the current carbon load and the current temperature of the particulate matter trap in the vehicle are acquired in real time.

[0045] The controller can determine the current carbon load of the particulate filter in real time according to the operating conditions of the vehicle engine, the Soot model (soot generation model), and the differential pressure model. A temperature sensor may be provided in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com