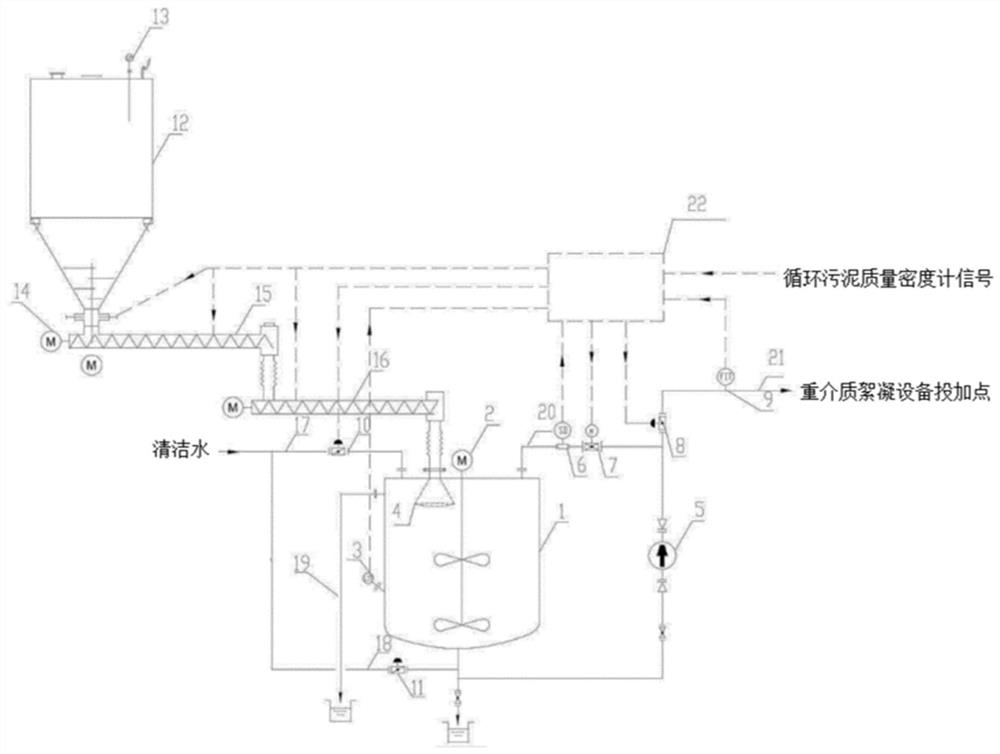

Automatic liquid-state preparation and feeding system for dense medium particles

A dense medium and dense medium powder technology, which is applied in transportation and packaging, mixers with rotating stirring devices, dissolution, etc., can solve the problems of easy hardening and sedimentation of heavy medium particles, high labor intensity, and inaccurate dosage , to achieve the effect of not easy to harden and silt, less maintenance workload, and accurate dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0082] The incoming water of a factory is the high-salt mine dredging water, which is softened, coagulated, clarified and softened by an integrated device. The maximum designed capacity of the device is 600m. 3 / h, the upward flow rate is 15-20m / s, and the influent water quality indicators are shown in Table 1 below:

[0083] Table 1 Influent water quality indicators

[0084] Ca 2+ (mg / L)

Mg 2+ (mg / L)

Turbidity (NTU) TDS(mg / L) Total alkalinity (mmol / L) 220 130 40 5000 2.48

[0085] The integrated device is equipped with an automatic liquid preparation and dosing system for dense medium particles. During the operation period, the preparation and supplementary dosing of the dense medium suspension is fully automatic without manual operation and maintenance.

[0086] The effective volume of the system heavy medium preparation box is 3m 3 , the set value of high liquid level H is 1.7m, the set value of low liquid level L is 0.5m, and the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com