Dry-type sampling method and device for easily-hydrolyzed brittle soft rock standard test piece

A standard test piece and sampling device technology, applied in the field of rock mechanics, can solve the problems of low sample preparation success rate, rock property change, high cost, and achieve the effect of reducing preparation cost, ensuring integrity and accuracy, and easy grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

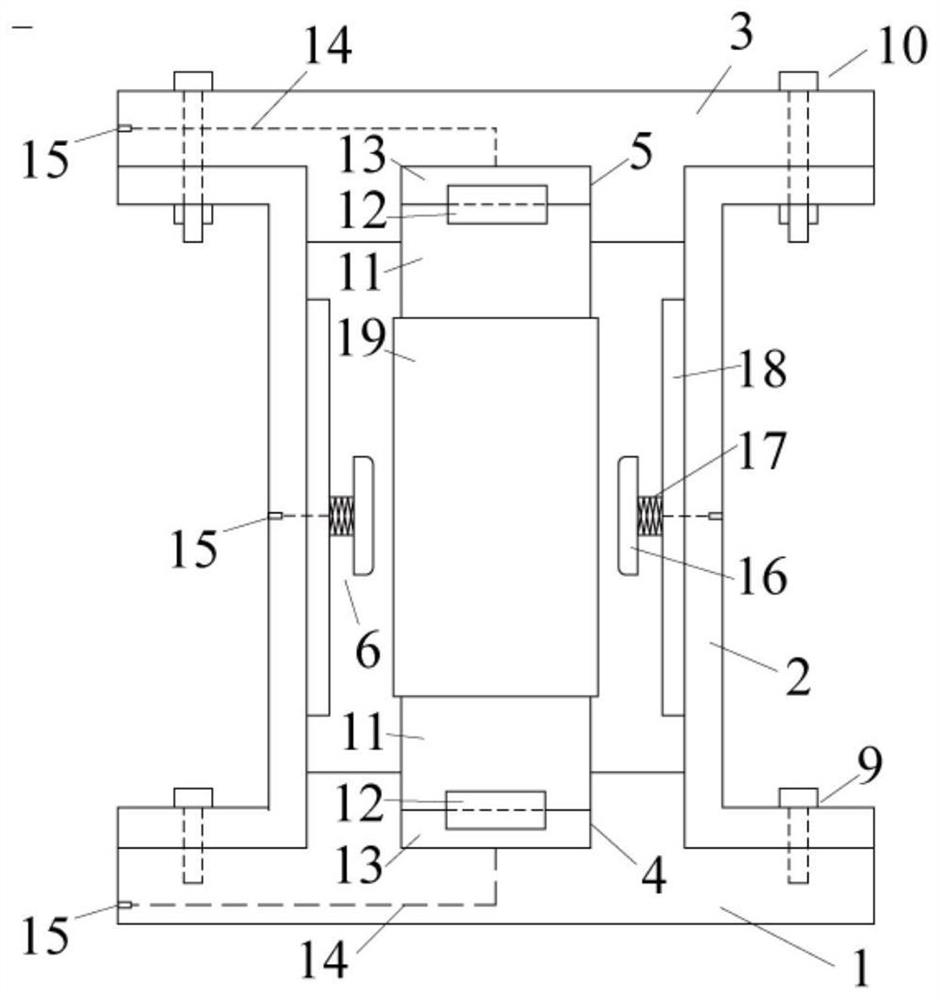

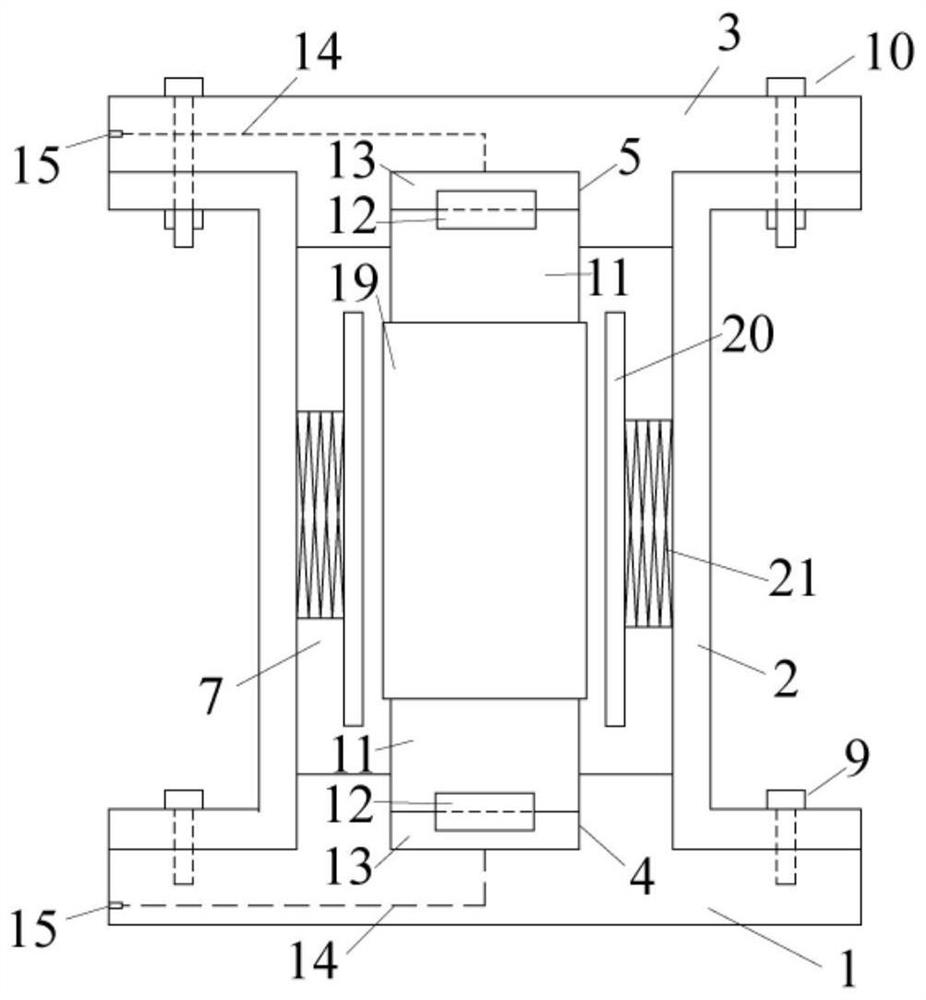

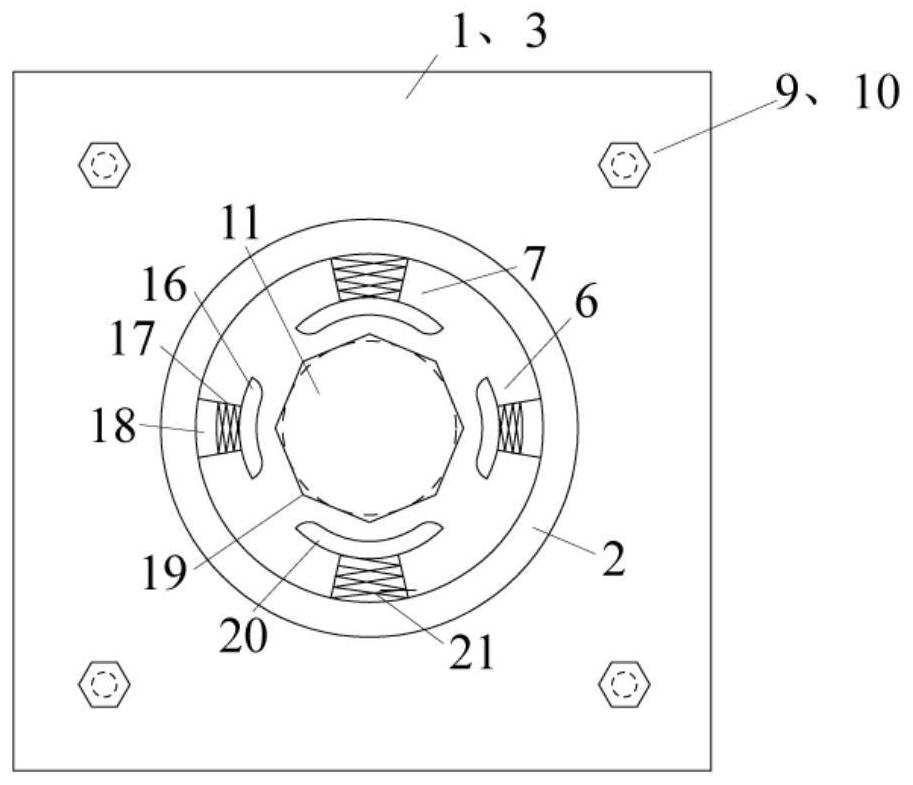

[0031] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples are only used to explain the present invention, but not to limit the scope of the present invention.

[0032] like Figure 1-Figure 4 As shown in the figure, the present invention is a dry sampling device for a standard specimen of easily hydrolyzed brittle soft rock. The sampling device includes a base 1, a processing chamber 2, a top module 3, a lower rotation module 4, an upper rotation module 5, and a longitudinal friction component 6. , radial friction assembly 7, loading control assembly 8; machining chamber 2 and base 1 are positioned and connected by bolts 9; machining chamber 2 and top module 3 are positioned and connected by adjustable bolts 10;

[0033] The lower rotating module 4 includes a rotating body 11, a connecting piece 12, and a rotating control block 13; the rotating control block 13 in the lower rotating block modul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inscribed circle diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com