Tubular close-range shock wave tester

A shock wave and short-distance technology, which is applied in the field of tubular short-distance shock wave tester, can solve problems such as difficult calculation and analysis, inability to accurately respond to explosion field parameters, etc., and achieve the effect of simple use, good application prospects, and compact device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

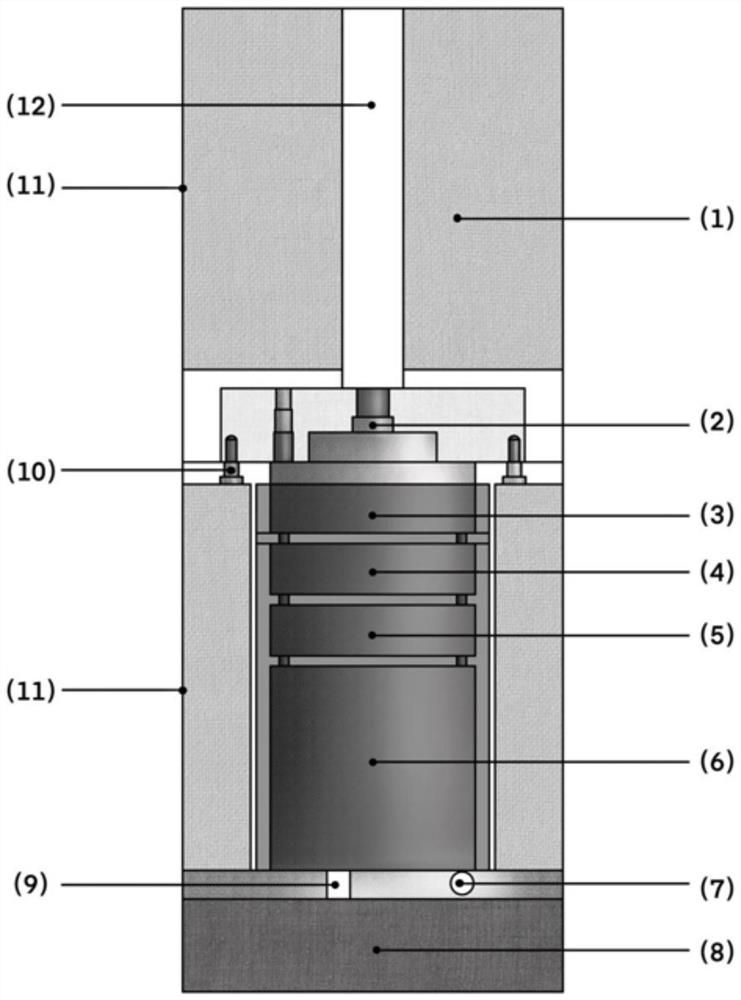

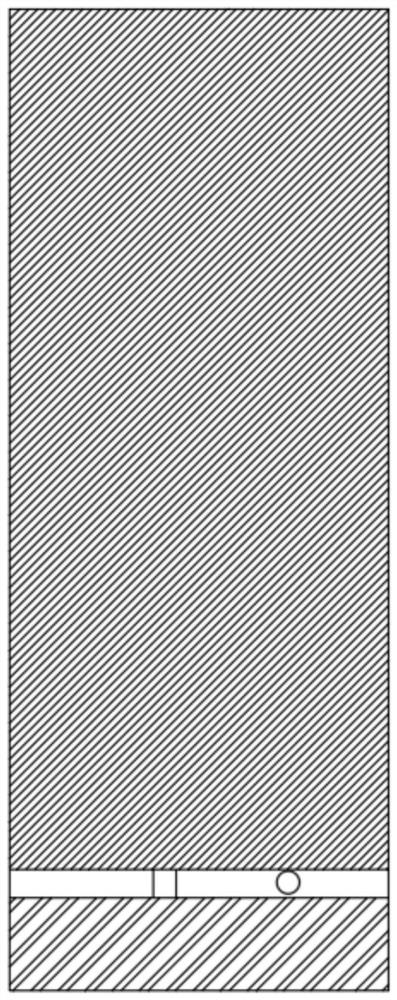

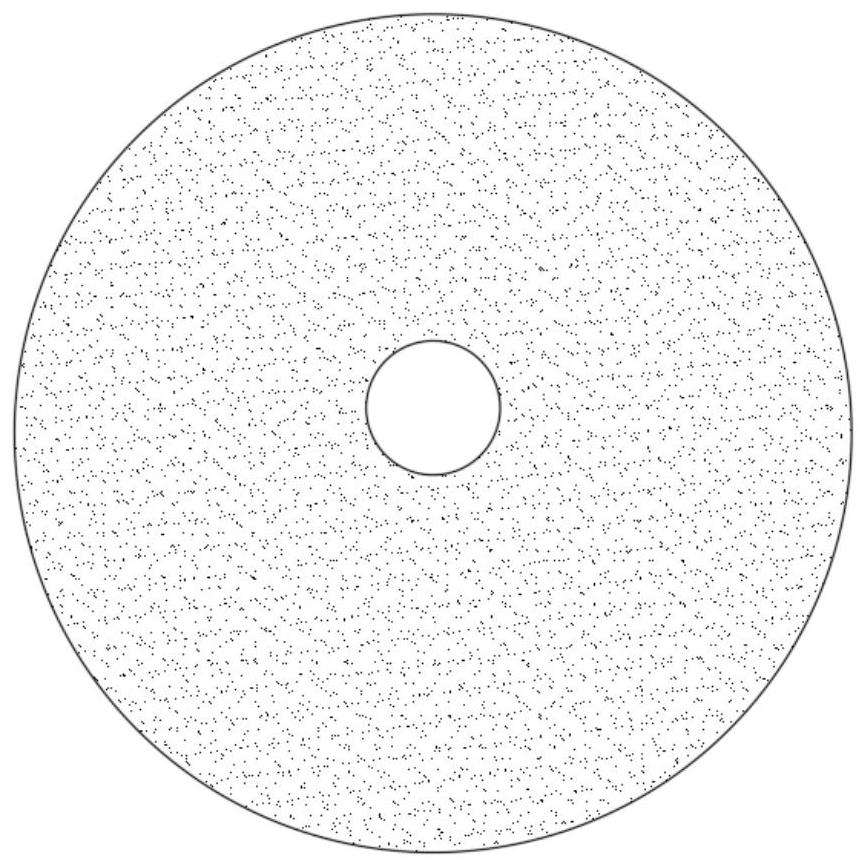

[0026] In accordance with the above technical requirements, this implementation case gives a safe energy-gathering punch such as Figure 1 to Figure 6 As shown, it specifically includes: 1-Composite cushioning material, 2-Pressure sensor, 3-Support beam, 4-Signal processor, 5-Information storage, 6-Power supply device, 7-Start button, 8-Device base , 9-switch, 10-connecting bolt, 11-metal shell, 12-tube receiver.

[0027] The whole device is cylindrical and wrapped by a metal shell, which protects the internal components of the device.

[0028] The pressure sensor module is used to sense the explosion shock wave and convert the compression wave signal into a charge signal output.

[0029] The signal processor module is used to analyze and filter the charge signal input by the sensor, and convert the charge signal into digital information output.

[0030] The information storage is used to record and save the finally obtained digital information, which is convenient for vario...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com