Advanced control system and control method of boiler device

A boiler device and advanced control technology, applied in the field of control, can solve the problems of large fluctuations in process parameters and low degree of automatic control of the boiler device, and achieve the effect of improving the automatic control rate and realizing the automatic and intelligent control of the boiler device operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

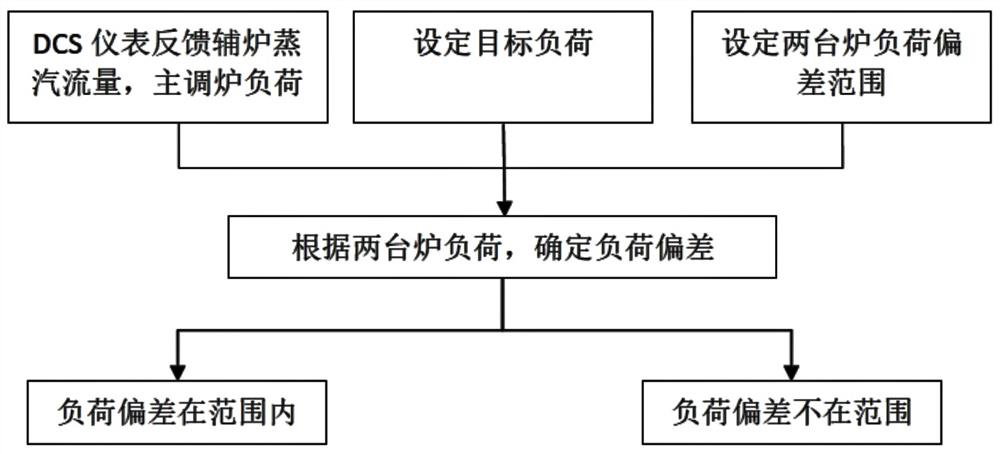

[0092] In this embodiment, the simultaneous operation of one main adjustment furnace and one auxiliary furnace is taken as an example for description.

[0093] Main furnace control:

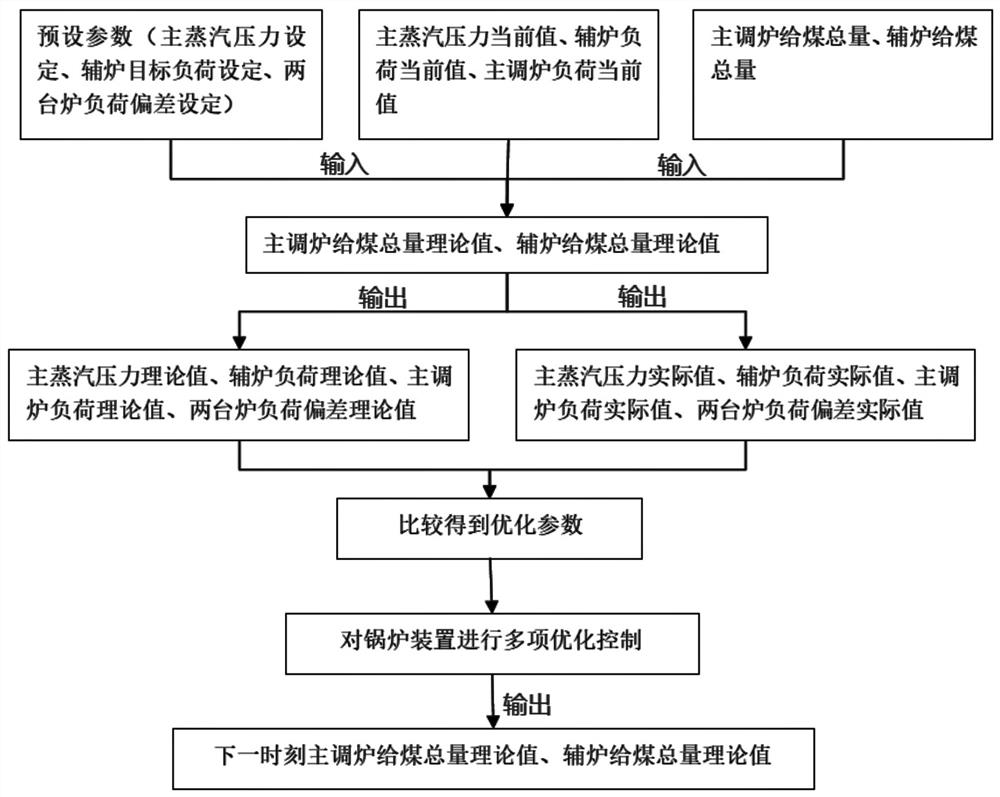

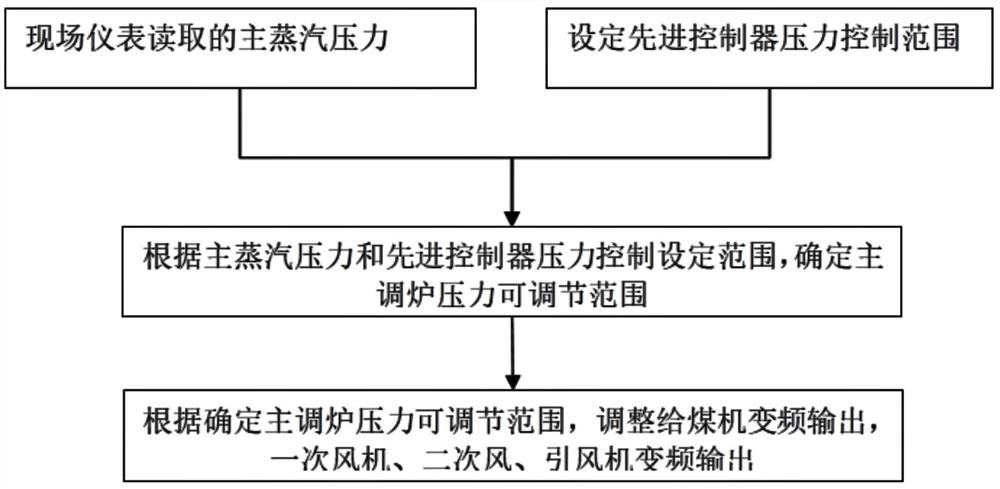

[0094] Step 1: Set the main steam pressure control range, the advanced controller calculates the required steam production according to the main steam pressure set value and the current value and change trend of the main steam pressure;

[0095] Step 2: The advanced controller calculates the gain of coal and steam as the coal calorific value at the current moment according to the total amount of coal fed and the amount of steam generated in the previous period. The amount of steam and the calorific value of coal at the current moment are calculated to obtain the total amount of coal required;

[0096] Step 3: The advanced controller calculates the coal feeding amount of 4 coal feeders according to the total coal feeding amount calculated in the second step and according to the coal feeder deviat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com