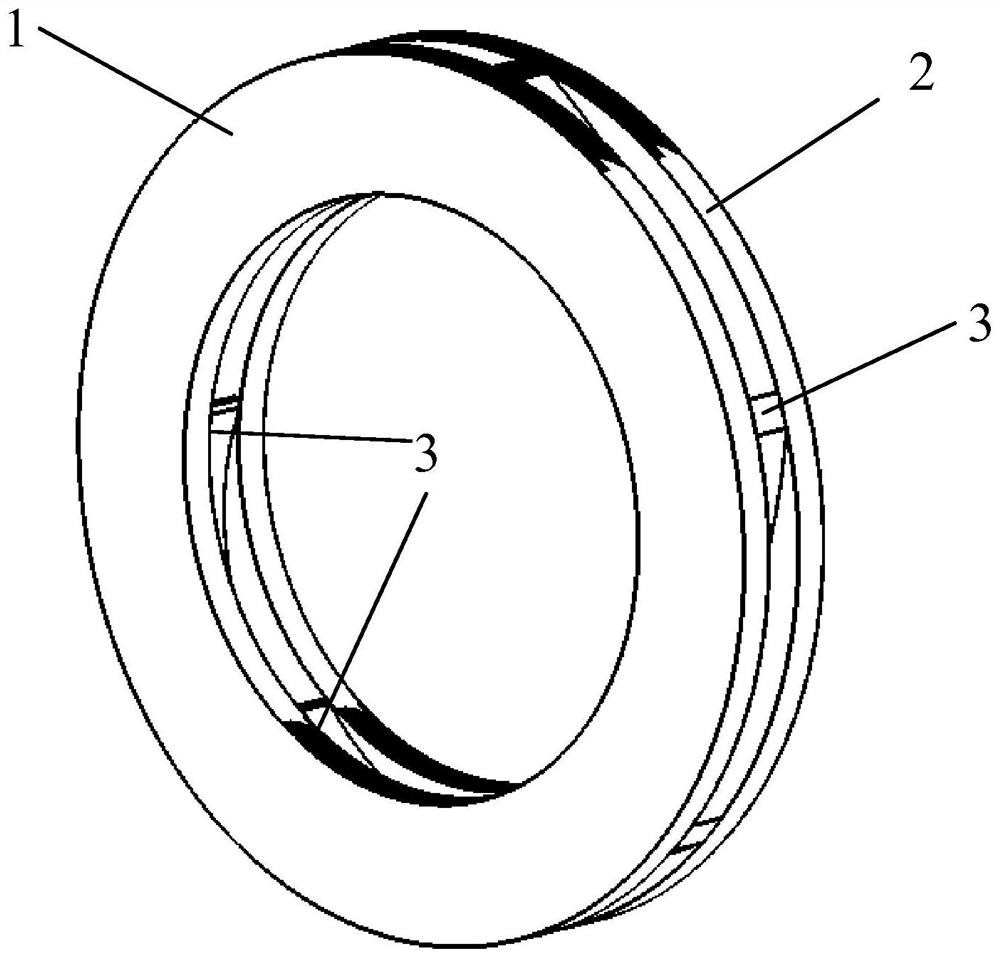

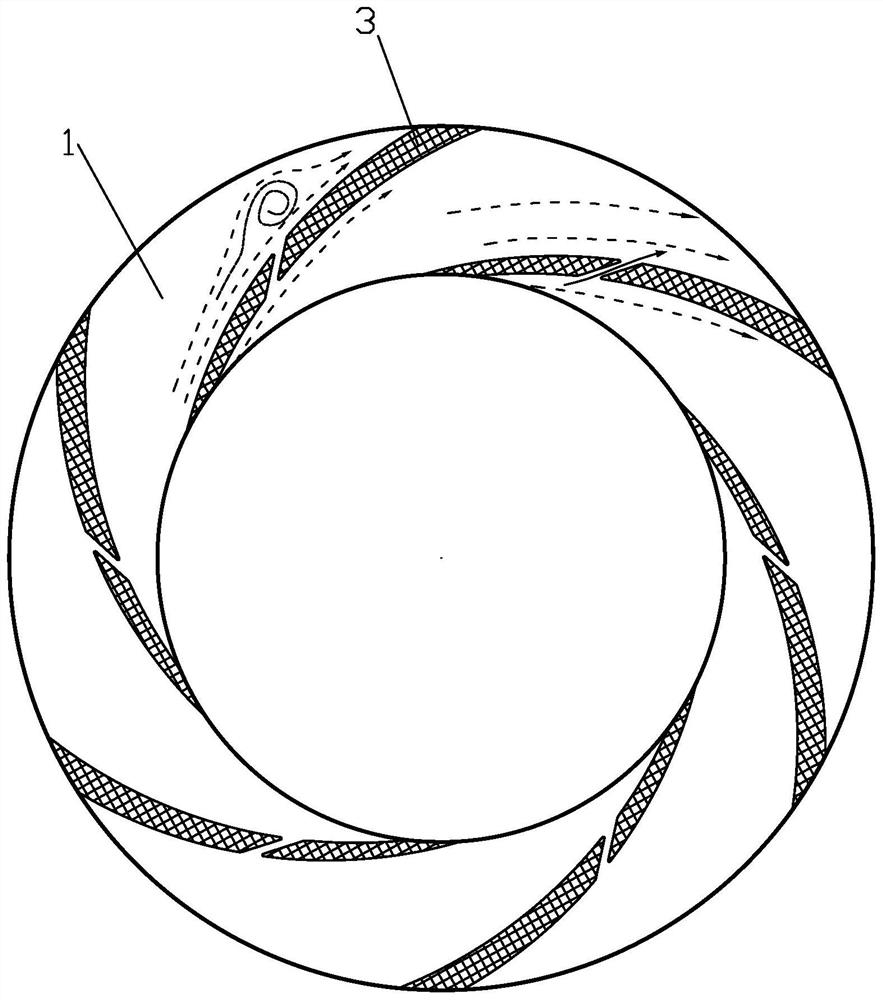

Gap drainage blade type diffuser for centrifugal pump

A diffuser and vane type technology is applied in the field of slit drainage vane diffusers for centrifugal pumps, and can solve the problems of reducing the flow stability of the diffuser, weakening the pressure recovery of the diffuser, affecting the safety and efficiency of operation, etc. Achieve the effect of improving the circumferential unevenness of the flow field, reducing the risk of stalling, and being easy to process and implement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

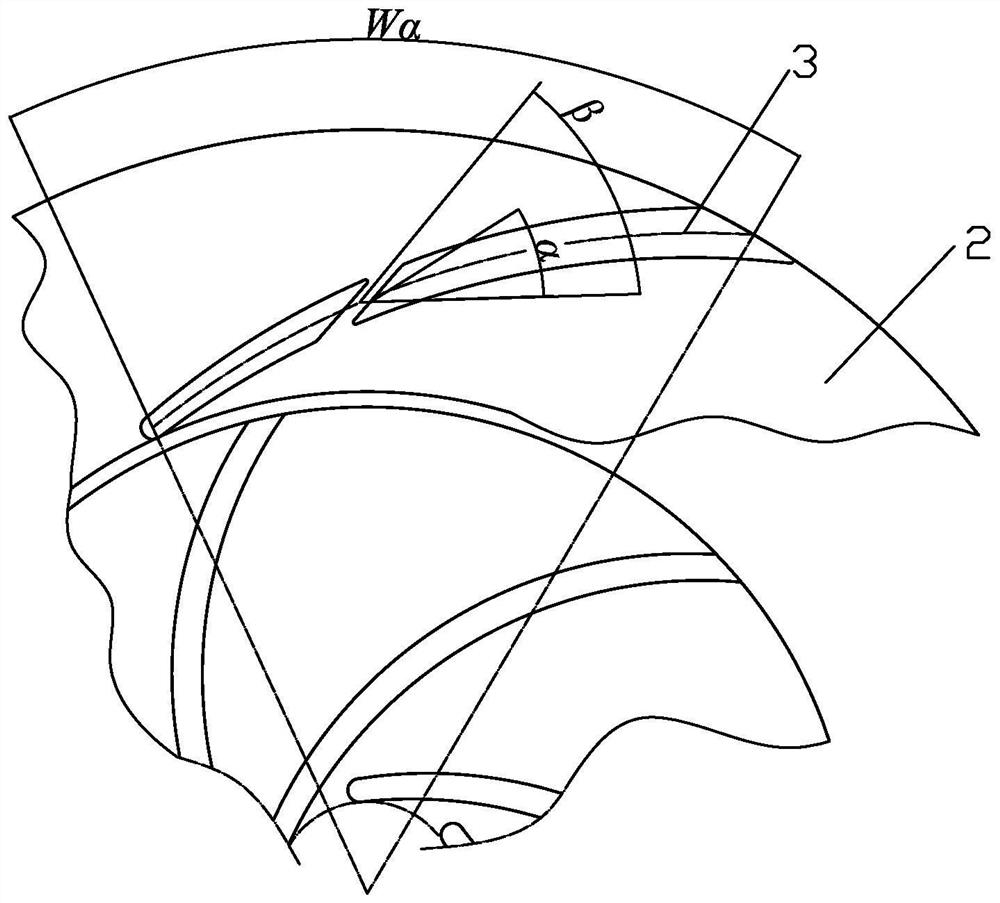

[0033] The blade wrap angle Wa=58°, the length of the bone line l=66mm, the length of the slit from the inlet edge bone line l1=30mm, the blade placement angle α=12.7° based on the bone line at the slit, the inclination angle of the slit β=50.3°, Slot width b2=2.4mm, blade width b1=2.6mm at the slit,

[0034] According to the formula lc=l1 / l of the relative position of the gap, lc=30 / l=0.455,

[0035] According to the calculation formula bc=b2 / b1 of the relative width of the gap, it can be calculated that bc=2.4 / 2.6=0.923,

[0036] According to the calculation formula θ=(β+α) / α of the relative inclination coefficient of the slot, θ=(50.3°+12.7°) / 12.7°=4.96° can be obtained.

Embodiment 2

[0038] The blade wrap angle Wa=55°, the length of the bone line l=76.6mm, the length l1=29.5mm between the slit and the bone line of the inlet side, the blade placement angle at the slit is based on the bone line α=22°, the inclination angle of the slit β=48 °, the slit width b2=3mm, the blade width b1=4.5mm at the slit;

[0039] According to the calculation formula lc=l1 / l of the relative position of the gap, it can be obtained that lc=0.385,

[0040] According to the calculation formula bc=b2 / b1 of the relative width of the gap, it can be obtained that bc=0.667,

[0041] According to the calculation formula θ=(β+α) / α of the relative inclination coefficient of the gap, it can be obtained that θ=3.182,

Embodiment 3

[0043] The blade wrap angle Wa=66°, the length of the bone line l=180mm, the length of the slit from the inlet edge bone line l1=111.6mm, the blade placement angle at the slit is based on the bone line α=12°, the inclination angle of the slit β=36° , the width of the slit is b2=4.5mm, and the width of the blade at the slit is b1=7.5mm;

[0044] According to the calculation formula lc=l1 / l of the relative position of the gap, it can be obtained that lc=0.62,

[0045] According to the calculation formula bc=b2 / b1 of the relative width of the gap, it can be obtained that bc=0.6,

[0046] According to the calculation formula θ=(β+α) / α of the relative inclination coefficient of the gap, it can be obtained that θ=4,

[0047] The following table is a comparison table of comprehensive indicators before and after improvement:

[0048] Performance parameters of centrifugal pumps using traditional guide vanes:

[0049]

[0050] Use the performance parameters of the centrifugal pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com