Method and system for evaluating flame retardance of flame arrester, and electronic equipment

A flame arrester and fire arresting technology, applied in the field of fire arresting safety, can solve problems affecting the smooth operation of the device, high testing efficiency, and inconvenient testing, and achieve the effects of high testing efficiency, improved fire arresting performance, and short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

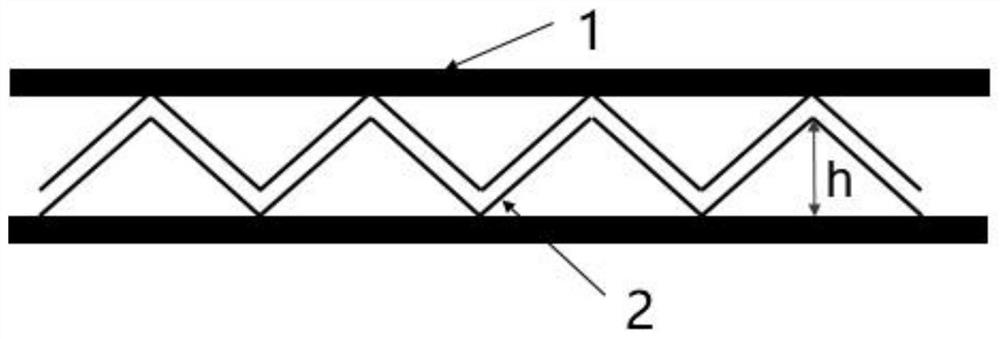

[0072] Provide a model of DN150, IIA type pipeline detonation type flame arrester in service, using corrugated plate flame arrester as the flame arrester unit, where the design value of the flame arrester gap is 0.75±0.05mm, and the outer diameter of the flame arrester is 310mm. The overall thickness is 80mm, and the thickness of a single piece is 20mm.

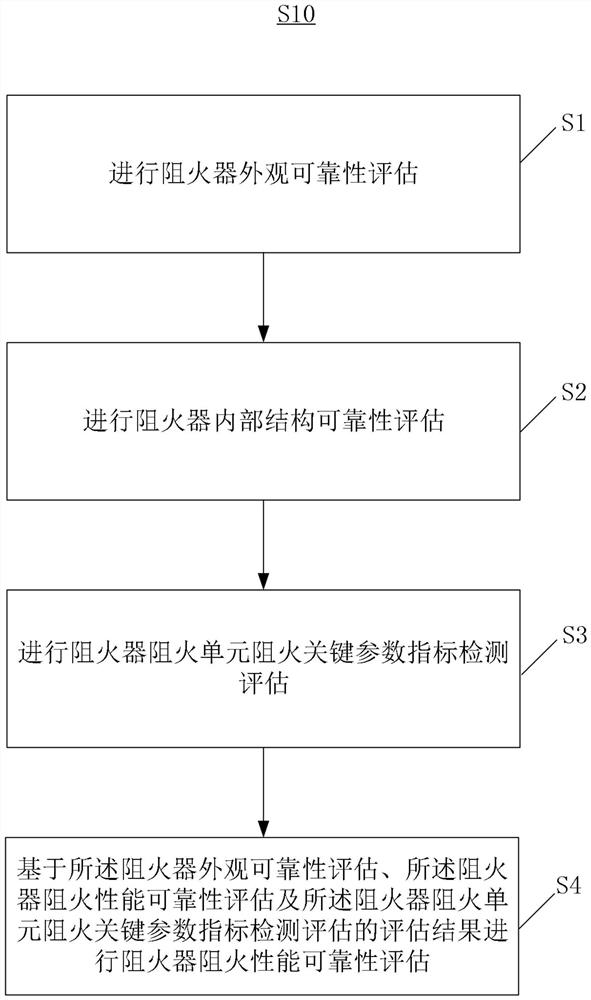

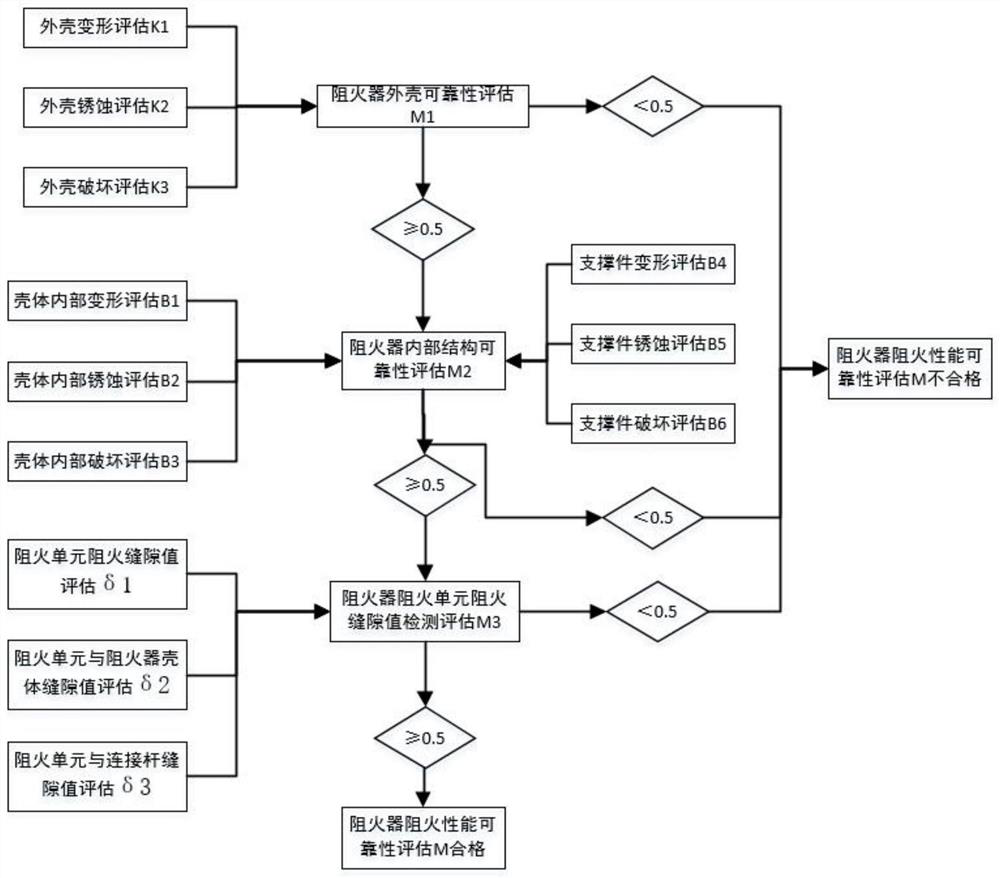

[0073] see figure 2 , According to the above-mentioned evaluation method of flame arrester fire resistance performance, the reliability of the appearance of the flame arrester, the reliability of the internal structure of the flame arrester, and the detection of the key parameters of the flame arrester flame arrester are evaluated respectively. The reliability evaluation of the flame arrester's fire resistance performance is mainly based on the analysis of the results between the three, and the reliability parameter M=M1*M2*M3 of the flame arrester's fire resistance performance is obtained. When M3 ≥ 0.125 and M1, M2, M3 ar...

Embodiment 2

[0106] The qualitative evaluation method is adopted, and the 3oo2 method is used to judge whether the appearance of the flame arrester fails. For example, when more than two kinds of appearance deformation, corrosion and structural damage occur, the appearance of the flame arrester is judged to be invalid (the quantitative index of the appearance of the flame arrester is simplified). When the evaluation result is qualified, it can be recorded as 1, when it is not qualified, it is recorded as 0, and it is recorded as 0.5 when the judgment is not good.

[0107] For this flame arrester, the reliability evaluation of the appearance of the flame arrester and the reliability evaluation of the internal structure of the flame arrester are as described in Example 1, so M1=M2=1.

[0108] (23) Detection and evaluation of key parameters of flame arrester flame arrester flame arrester

[0109] Adopt the same method as Example 1 to obtain M3=0.5.

[0110] (24) Reliability evaluation of fla...

Embodiment 3

[0113] For the flame arrester in Example 1, the reliability of the appearance of the flame arrester, the reliability of the internal structure of the flame arrester, and the detection of the key parameters of the flame arrester flame arrester were evaluated.

[0114] The reliability evaluation of the appearance of the flame arrester and the reliability evaluation of the internal structure of the flame arrester are performed using the same method as in Embodiment 1, and will not be repeated here.

[0115] (33) Detection and evaluation of key parameters of flame arrester flame arrester flame arrester

[0116] For the inconvenience of dismantling the fire arrester unit, there are flame arresters that are difficult to install again after dismantling, and the gap value evaluation of the outer fire arrester unit can be used. In order to ensure the reliability of the data, the number of sampling points is doubled on the basis of the original suggestion. The sampling data is shown in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com