Treatment equipment for industrial acidic sewage

A technology for acid sewage and treatment equipment, which is applied in the fields of water/sewage multi-stage treatment, neutralized water/sewage treatment, water/sludge/sewage treatment, etc. Treatment efficiency and other issues, to achieve the effect of improving sewage neutralization treatment efficiency, speeding up neutralization treatment efficiency, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

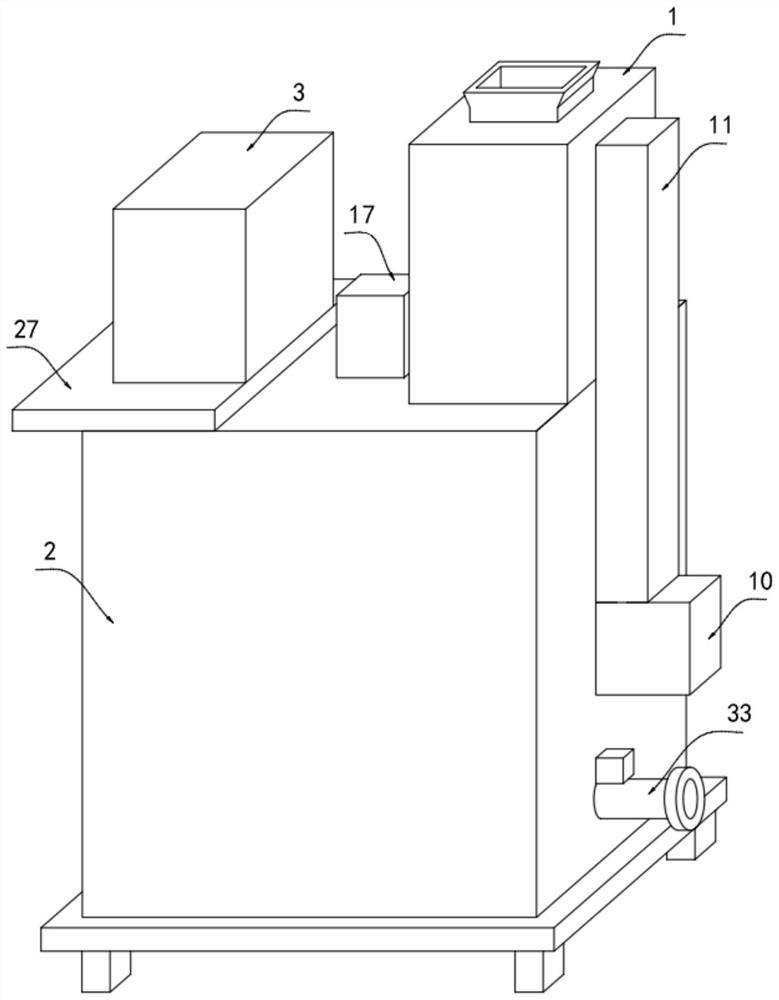

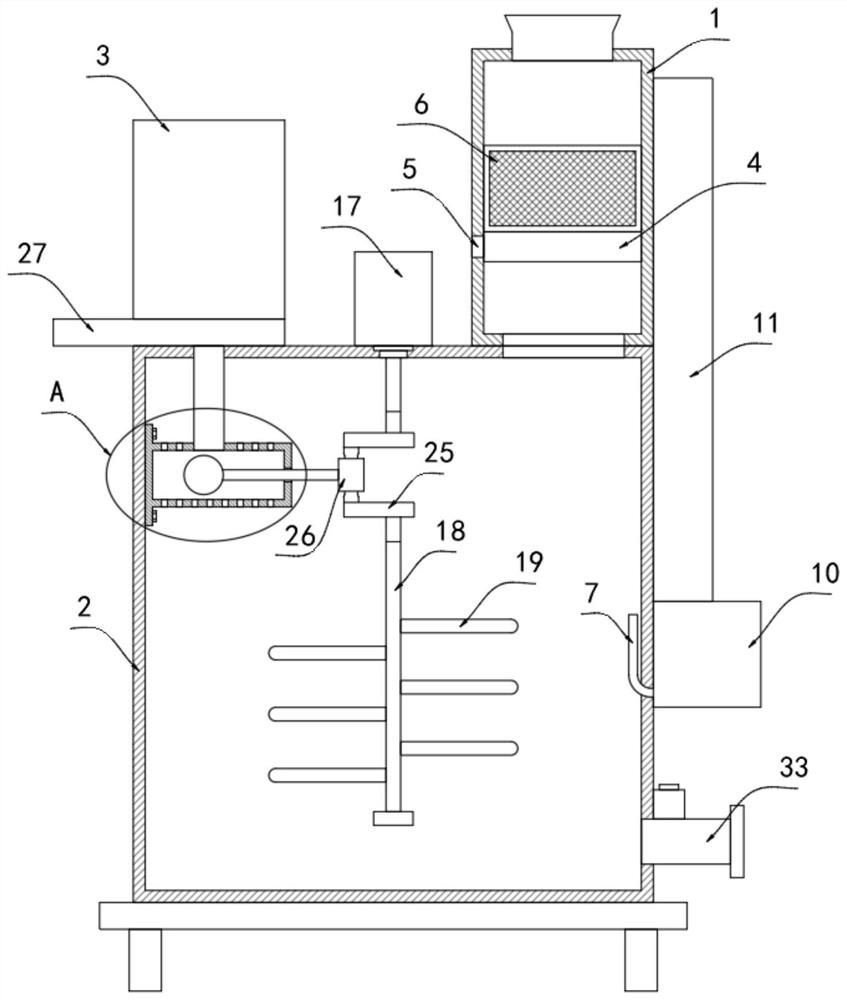

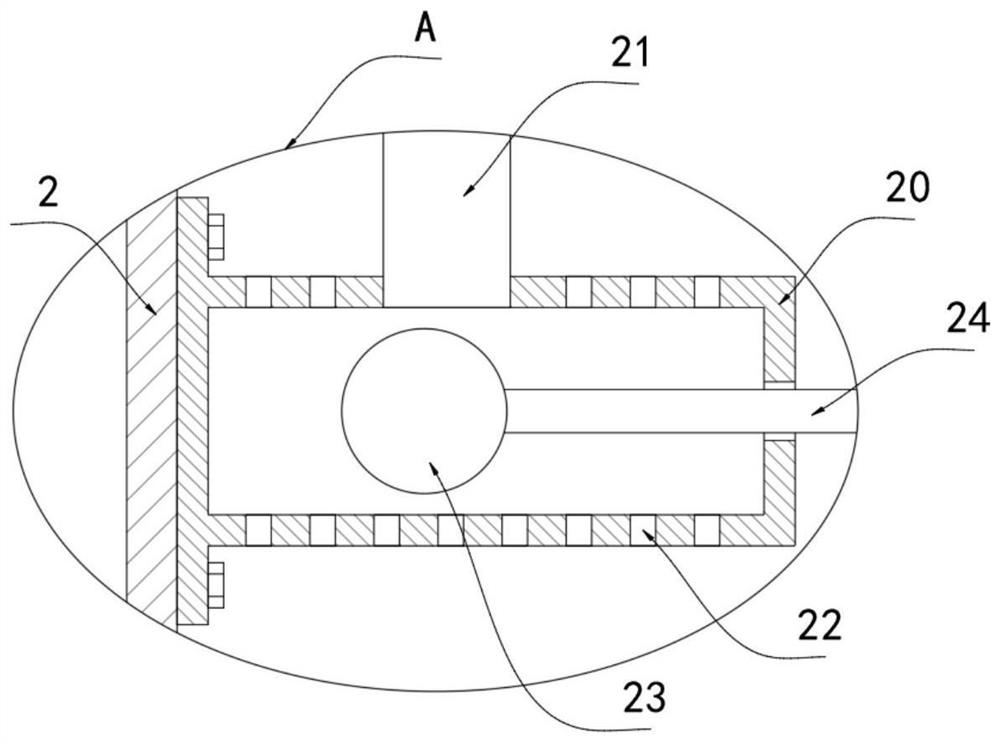

[0029] like figure 1 As shown, a treatment equipment for industrial acid sewage includes a filter box 1 and a neutralization box 2, the filter box 1 is arranged above the neutralization box 2, the upper end of the filter box 1 is provided with a feeding port, and the filter box 1 The bottom of the neutralization box 2 is communicated with the interior of the neutralization box 2. A drainage pipe 33 is fixedly connected to the bottom side wall of the neutralization box 2. A solenoid valve is installed at the connection between the drainage pipe 33 and the neutralization box 2. A filter mechanism is provided in the filter box 1. , The top of the neutralization box 2 is provided with a feeding box 3, the feeding box 3 is filled with an alkaline neutralizer, the alkaline neutralizer is limestone, and the neutralizing box 2 is provided with a stirring mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com