Ultrahigh vacuum two-dimensional material preparation system and preparation method

A two-dimensional material, ultra-high vacuum technology, used in nanostructure manufacturing, nanotechnology, nanotechnology and other directions to avoid pollution and avoid oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

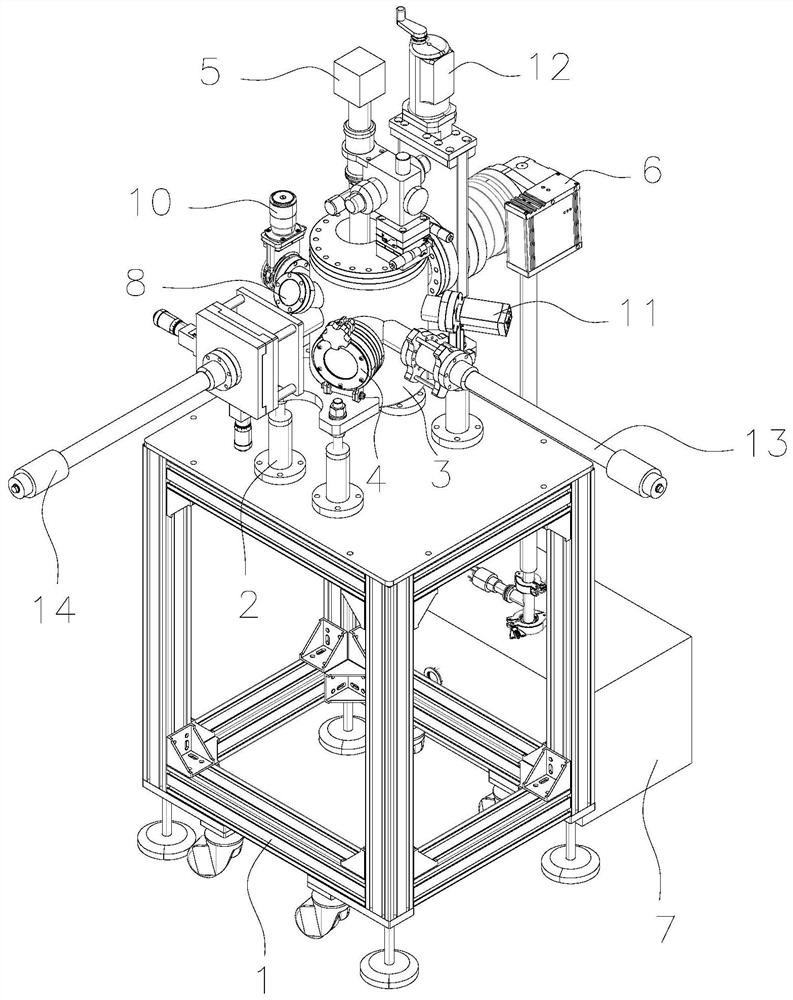

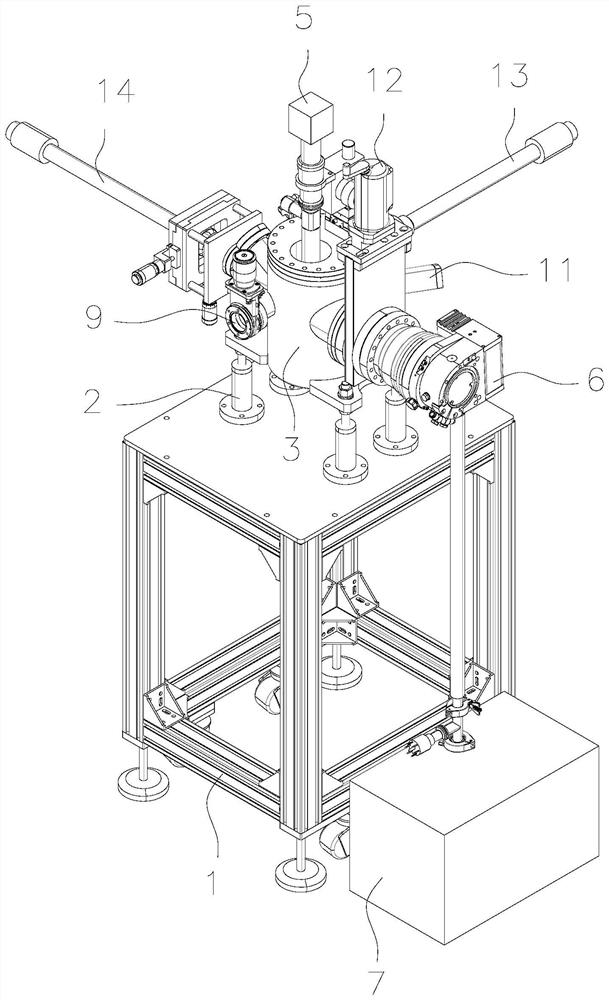

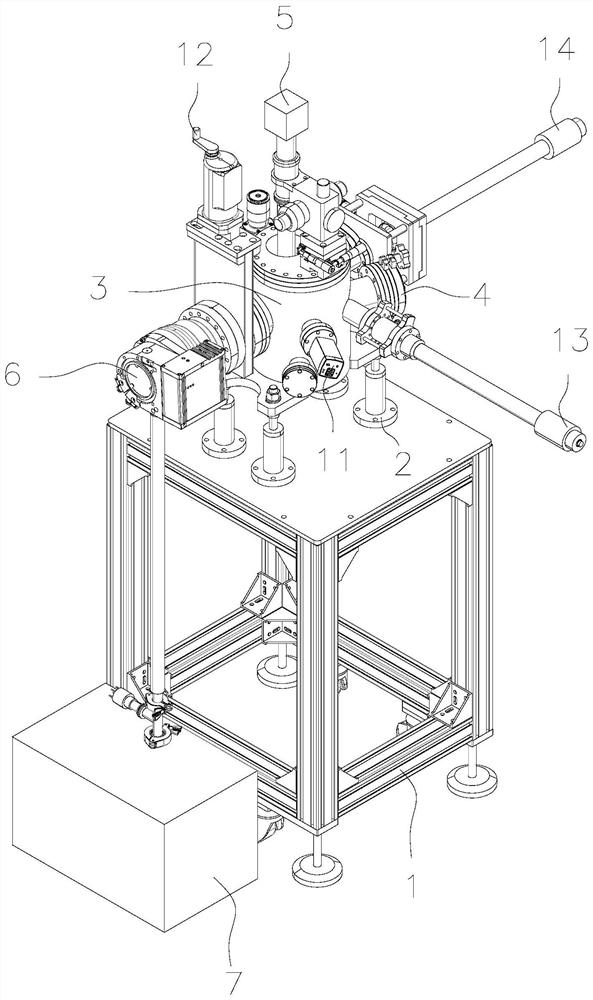

[0041] The embodiment of the present invention provides an ultra-high vacuum two-dimensional material preparation system. Figure 1-6 , including the system bracket 1 as the installation platform, on the system bracket 1 is installed the ultra-high vacuum chamber 3 through the fixing frame 2, the ultra-high vacuum chamber 3 is made of high-quality 316 stainless steel, and the leakage rate of the chamber is lower than 1× 10 -10 mbar·L / s, the ultra-high vacuum chamber 3 is provided with:

[0042] The vacuum chamber door 4 is used for rapid replacement of two-dimensional material samples inside and outside the ultra-high vacuum chamber 3;

[0043] The telephoto microscope 5 is used to observe the prepared two-dimensional material sample;

[0044] The vacuum pump set is used to evacuate the inner cavity of the ultra-high vacuum chamber 3 and maintain the ultra-high vacuum environment of the inner cavity of the ultra-high vacuum chamber 3; in this embodiment, the vacuum pump set ...

Embodiment 2

[0055] The difference between this embodiment and Embodiment 1 is that, such as Figure 1-4 As shown, the ultra-high vacuum chamber 3 is provided with interconnecting pipes 9 that can be connected with other chambers, for transferring the prepared two-dimensional material samples to other ultra-high vacuum chambers for testing, and the interconnecting pipes 9 There is a first gate valve 10 on it that cuts off the connection between other cavities and the ultra-high vacuum cavity 3, which ensures that the prepared two-dimensional material can be transferred to other cavities for testing by testing equipment without exposing to the atmosphere. In order to reflect the most essential characteristics of two-dimensional materials during testing.

[0056] For other undescribed structures, refer to Embodiment 1.

Embodiment 3

[0058] The present invention also provides a preparation method for preparing two-dimensional materials by using an ultra-high vacuum two-dimensional material preparation system, comprising the following steps:

[0059] S1. Adhering the two-dimensional material sample to the substrate of the first sample holder 24 by PDMS (polydimethylsiloxane), and loading the first sample holder 24 on the mechanical gripper 19, and passing the The opened vacuum chamber door 4 is sent into the ultra-high vacuum chamber 3, and then the vacuum chamber door 4 is closed;

[0060] S2. Turn on the vacuum pump set composed of the molecular pump 6 and the mechanical pump 7 to evacuate the inner cavity of the ultra-high vacuum chamber 3. After the inner cavity of the ultra-high vacuum chamber 3 reaches the ultra-high vacuum environment, keep the first sample holder 24 The two-dimensional material sample adhered to the top is in an ultra-high vacuum environment;

[0061] S3. Manipulate the sample rack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com