Oily impermeable cloth closed feeding system and feeding method

A feeding system and feeding technology, applied in the furnace, loading/unloading, furnace type, etc., can solve the problems of uneven characteristics, miscellaneous oil-containing anti-seepage materials, and inability to ensure the health and safety of workers. The effect of high feed efficiency and accurate metering of feed amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

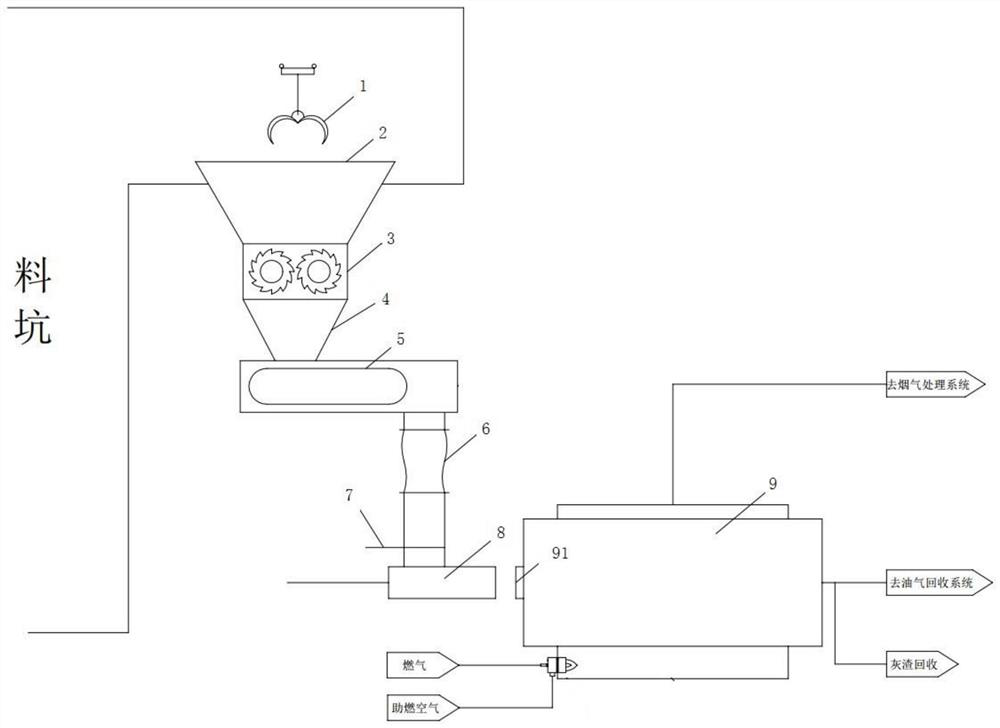

[0032] like figure 1 As shown, in a specific embodiment, the oil-containing anti-seepage cloth airtight feeding system includes a grab feeding device 1, a primary storage bin 2, a shredder 3, a secondary storage bin 4, a Conveyor 5, flexible connecting pipe 6, flapper valve 7, push rod feeding device 8, mobile trolley (not shown), rotary kiln pyrolysis device 9; grab feeding device 1 is installed in the primary storage bin 2 Above the entrance; the opening of the grab feeding device and the primary storage bin is set in a closed space; the outlet of the primary storage bin 2 is connected to the entrance of the shredder 3; the outlet of the shredder 3 is connected to the entrance of the secondary storage bin 4 Connection; the outlet of the secondary storage bin 4 is connected with the inlet of the conveyor 5 with the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com