Fiber material, preparation method and device and hygienic product

A technology for fiber materials and sanitary products, applied in the field of non-woven fabrics and their preparation, can solve the problems of increasing three-dimensionality, elasticity and resistance to deformation, poor permeability/air permeability, and poor resistance to deformation of bulging bags, so as to increase the air Good circulation and air permeability, good three-dimensional retention, good comfort and good aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

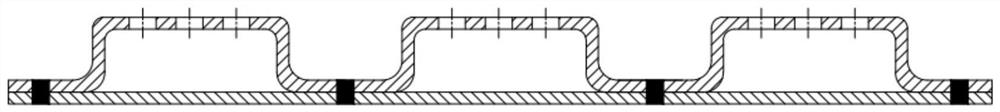

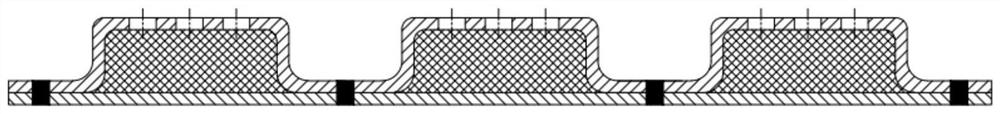

[0089] The surface layer of the fiber material is made of 25 g / m2 whitening weakly hydrophilic hot air non-woven fabric, and the bottom layer is made of 20 g / m2 strong hydrophilic whitening hot air non-woven fabric. Figure 4 and Figure 5 Double layer composite fiber material shown. The diameter of the upper barb opening is about 2.5 mm, the length of the upper barb is about 1.25 mm, the diameter of the lower barb opening is about 2.5 mm, and the length of the lower barb is about 1.2 mm. The hole diameter of the side barb is about 2.5mm, and the length of the side barb is about 1.25mm.

Embodiment 2

[0091] The surface layer of the fiber material is made of 20 g / m² whitening weakly hydrophilic hot air non-woven fabric, and the bottom layer is made of 18 g / m² light blue strong hydrophilic hot air non-woven fabric. Figure 4 and Figure 5 Double layer composite fiber material shown. The diameter of the upper barb opening is about 2.0 mm, the length of the upper barb is about 1.0 mm, the diameter of the lower barb opening is about 2.0 mm, and the length of the lower barb is about 1.0 mm. The hole diameter of the side barb is about 2.0mm, and the length of the side barb is about 1.0mm.

Embodiment 3

[0093] The surface layer of the fiber material is made of 35 g / m² whitening strong hydrophilic hot air non-woven fabric, and the bottom layer is made of 35 g / m² whitening strong hydrophilic hot air non-woven fabric. Figure 9 Double layer composite fiber material shown. The diameter of the upper barb opening is about 3.0 mm, the length of the upper barb is about 1.8 mm, the diameter of the lower barb opening is about 3.0 mm, and the length of the lower barb is about 1.8 mm. The hole diameter of the side barb is about 2.0mm, and the length of the side barb is about 1.0mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com