Wafer cleaning device and cleaning method

A technology for cleaning devices and wafers, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as reducing and reducing wafer yield, and achieve the effect of improving consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

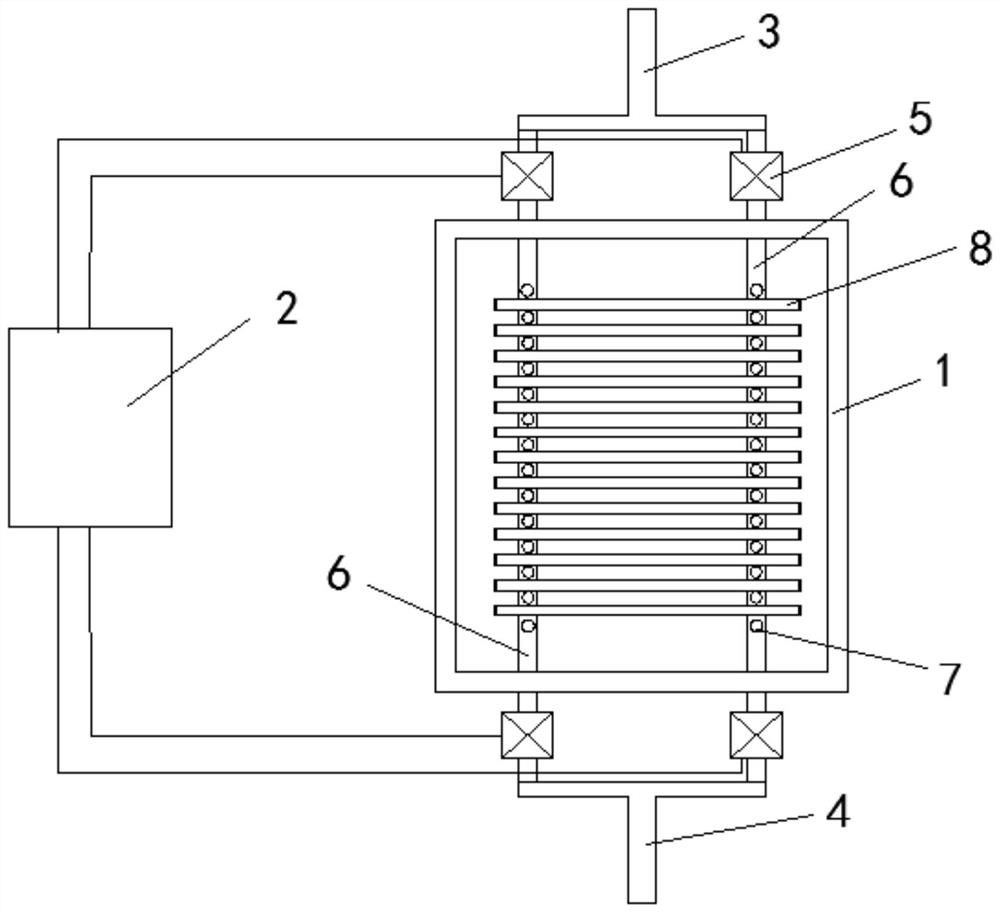

[0034] This embodiment provides a wafer cleaning device, which combines figure 1 , the wafer cleaning device includes: a cleaning tank 1 , an electronic control module 2 , a first infusion manifold 3 , a second infusion manifold 4 , four solenoid valves 5 and two infusion tubes 6 . Wherein, the two infusion tubes 6 are parallel to each other, and the two ends of each infusion tube 6 respectively penetrate the bottom of the two opposite side walls of the cleaning tank 1; the two ends of each infusion tube 6 are respectively provided with a liquid inlet; Each infusion pipe 6 is fixedly provided with a plurality of nozzles 7 along the length direction, and the nozzles 7 are all located in the cleaning tank 1; the first infusion main pipe 3 and the second infusion main pipe 4 are respectively located on opposite sides of the cleaning tank 1, and the two The liquid inlets of each infusion pipe 6 are respectively communicated with the corresponding first infusion main pipe 3 or the ...

Embodiment 2

[0039] The present embodiment provides a wafer cleaning method, including: providing two infusion pipes 6 , a plurality of nozzles 7 are arranged in the longitudinal direction of the two infusion pipes 6 , and the plurality of nozzles 7 are used for spraying the cleaning liquid on the wafer 8 , Both ends of the two infusion pipes 6 are respectively provided with a liquid inlet; the cleaning liquid is conveyed to the infusion pipes 6 through the liquid inlets, so that the nozzles 7 can clean the wafers 8 in the cleaning tank 1 .

[0040] Further, the method also includes: providing four solenoid valves 5, and the four solenoid valves 5 are respectively fixedly arranged at both ends of each infusion pipe 6; the flow rate of the cleaning liquid conveyed by the infusion pipe 6 is controlled by the solenoid valve 5, so that it is easy to change. The cleaning degree of the cleaning solution to the wafer 8 .

[0041] Further, the method further includes: providing an electronic contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com