Special crusher for producing compound feed for broiler chickens

A technology for compound feed and broiler chickens, which is applied in feed, application, agricultural machinery and implements, etc. It can solve problems such as loss of materials, pollution of the on-site operating environment, and bending of shafts, so as to prolong the effective service life and improve the crushing efficiency , the effect of high structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following descriptions are only preferred embodiments of the present invention, and do not limit the scope of the present invention.

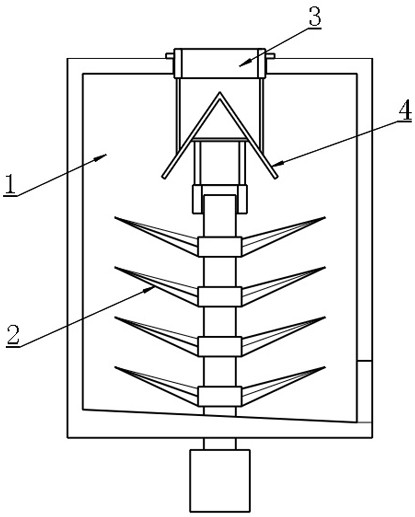

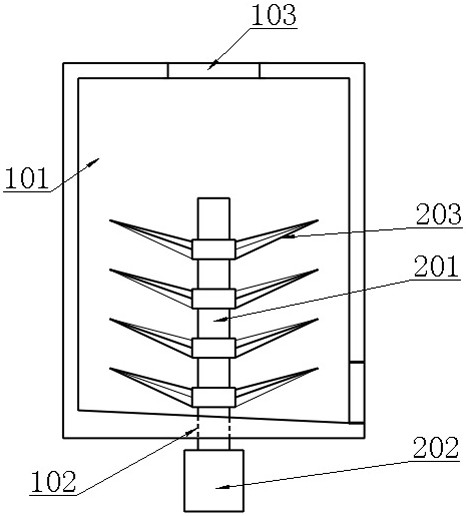

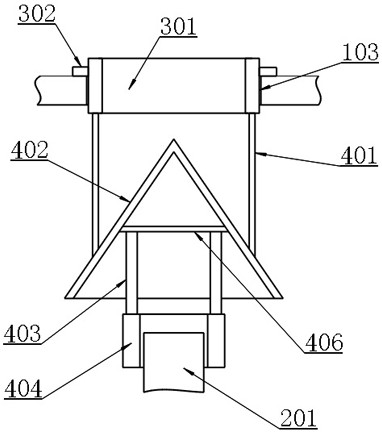

[0036] as attached Figure 1-6 As shown in the figure, a special grinder for the production of compound feed for broilers is characterized in that: it comprises a body unit 1, an inverted crushing knife unit 2 arranged on the bottom plate of the body unit 1, and an inverted crusher unit 2 arranged on the top plate of the body unit 1 The feed hole lining ring unit 3 is arranged at the lower end position of the feeding hole lining ring unit 3, and is sleeved with the upper end of the inverted pulverizing knife unit 2, and is used for the ring to be pulverized. Cone panel unit 4 for guide operation.

[0037] In this embodiment, the general use method and advantages of the raw material pulverizer for feed production are as follows.

[0038] First, the inverted crushing knife unit 2, the feed hole lining ring unit 3 and the conical pane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com