Vehicle-mounted millimeter wave radar

A millimeter-wave radar and housing technology, applied in the field of sensors, can solve the problems such as the inability to effectively meet the lightweight design requirements, the large size of the vehicle-mounted millimeter-wave radar casing, and the increase of the vehicle-mounted millimeter-wave radar process, etc., to achieve high assembly efficiency, The effect of reducing installation cost and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

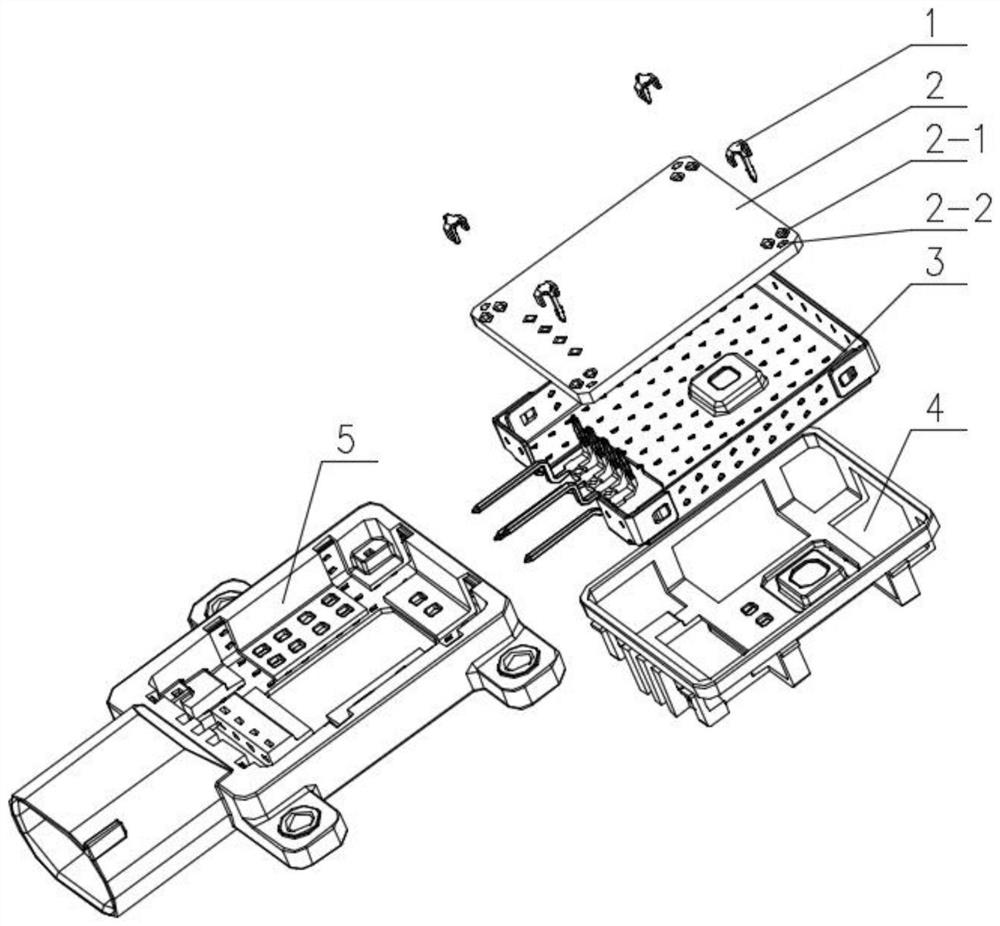

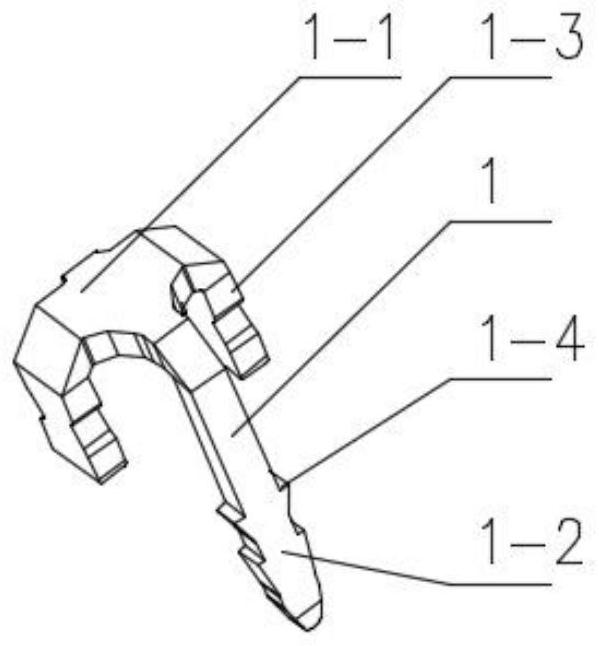

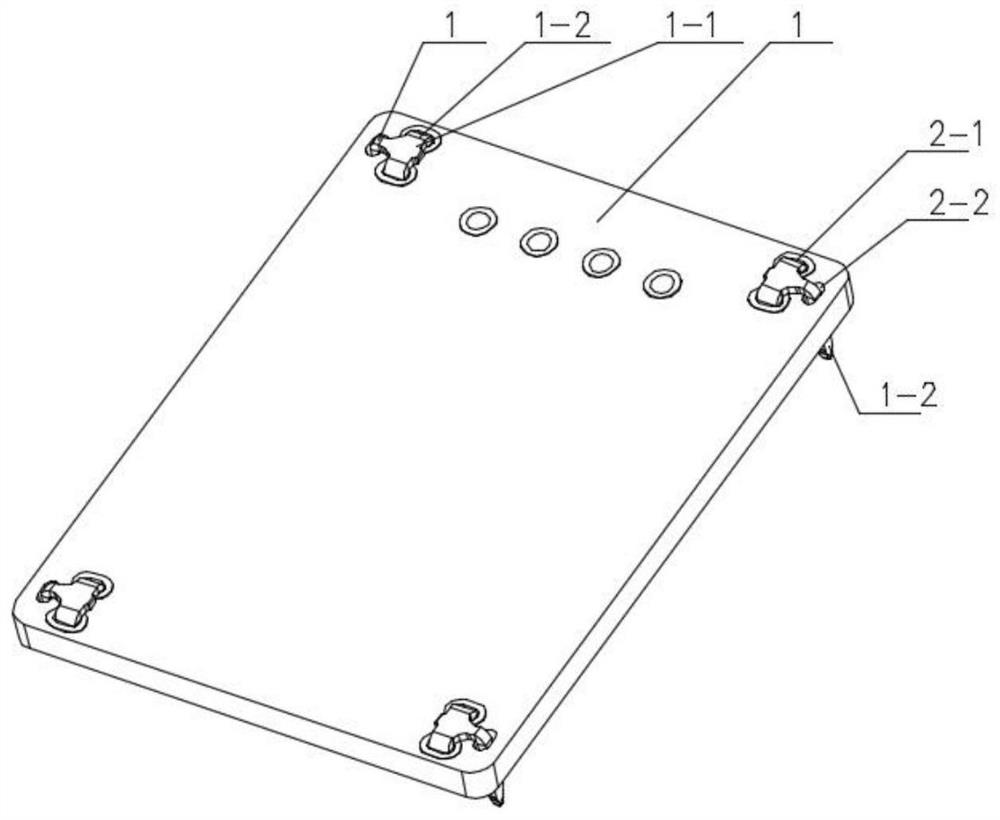

[0026] A vehicle-mounted millimeter-wave radar PCB, see figure 1 , Figure 4 , the PCB board 2 in the vehicle-mounted millimeter-wave radar and the base 4 in the vehicle-mounted millimeter-wave radar housing 5 are fixed by a plurality of rivets 1, and an open box-shaped shielding part 3 is installed in the base, and the shielding part is embedded Stamped metal parts in the injection molding cavity of the vehicle-mounted millimeter-wave radar housing.

[0027] The shielding part includes a bottom plate 3-1, the front and rear sides and the left and right sides of the bottom plate are respectively punched upwards with symmetrical front and rear side plates and symmetrical left and right side plates, and the four corners of the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com