Environment-friendly mould pressing door plate with formaldehyde removal function

A technology of functional boards and door panels, which is applied to door leaves, household appliances, heating methods, etc., can solve the problems of scratches on the surface of door panels, inconvenient photolysis, and affecting the service life of photocatalysts, etc., and achieve the effect of improving photolysis efficiency and service life

Active Publication Date: 2022-06-21

江苏真磊新材料有限公司

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Spray photocatalyst on the surface of some door panels, and degrade formaldehyde in the air through the photolysis of photocatalyst. As long as the photocatalyst coating is not worn or peeled off, the photocatalyst itself will not change and wear, and it can continuously purify pollutants under the irradiation of light. , but it is easy to scratch the surface of the door panel in daily life, so that the photocatalyst coating will fall off, which greatly affects the service life of the photocatalyst, and it is not convenient to protect the photocatalyst coating. At night, the photocatalyst is not convenient. photolysis

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

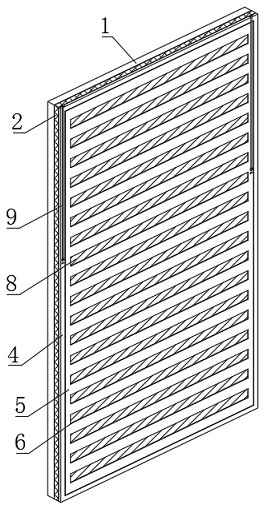

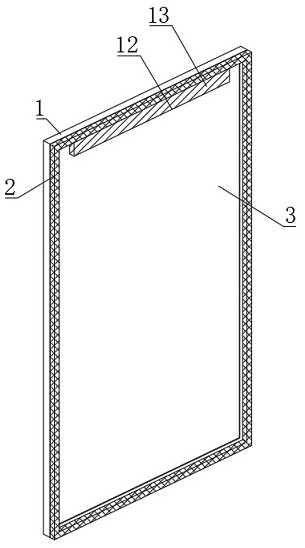

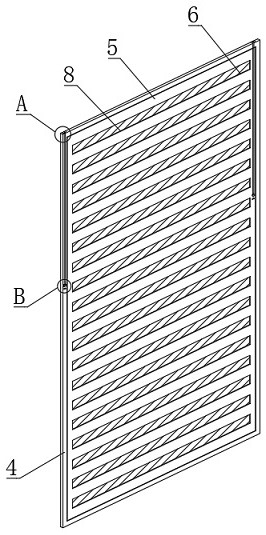

The invention discloses an environment-friendly mould pressing door plate with a formaldehyde removal function, and belongs to the field of door planks. The environment-friendly mould pressing door plate with the formaldehyde removal function comprises a metal door plate body, and a second mirror reflection coating right coincides with the position, not provided with a through groove, of a connecting plate; the light can cover the photocatalyst coating in a large range through the second specular reflection coating, the shading rate of the connecting plate is reduced, the photolysis efficiency of the photocatalyst coating is improved, the photocatalyst coating on the surface of the metal door plate body is protected through the ventilation frame, the fixing frame and the connecting plate, the possibility that the photocatalyst coating is scratched and falls off is reduced, and the service life of the metal door plate body is prolonged. The first mirror reflection coating and the second mirror reflection coating are also distributed in a staggered mode, a complete mirror effect is formed on the opposite face of the photocatalyst coating, the photocatalyst coating is completely covered with illumination of the fluorescent powder in cooperation with a complete mirror, and the photocatalyst coating still has a good photolysis effect at night.

Description

technical field [0001] The invention relates to the field of door panels, and more specifically relates to an environmentally friendly molded door panel with the function of removing formaldehyde. Background technique [0002] The formaldehyde in the indoor air mainly comes from the artificial wood boards used in decoration materials and new combined furniture, such as the adhesives in plywood, large-core board, MDF, and chipboard. Formaldehyde is released. Foam, which is used as an insulating material for housing heat protection and cold protection, can also release formaldehyde after aging under the action of light and heat. Products such as paints, chemical fiber carpets, cosmetics, and floor glue that use formaldehyde as a preservative can also slowly release formaldehyde. The smoke of each cigarette also contains 20-88 micrograms of formaldehyde. In addition, a small amount of formaldehyde comes from outdoor industrial waste gas, automobile exhaust and photochemical s...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E06B3/72F24F8/158F24F8/167

CPCE06B3/72F24F8/158F24F8/167

Inventor 田延宽

Owner 江苏真磊新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com