Pipe fitting chamfering machine for fitness equipment production and processing

A technology of fitness equipment and chamfering machine, which is applied in metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of poor cooling effect, shorten the service life of chamfering knives, and increase the temperature of chamfering knives, and achieve cooling good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

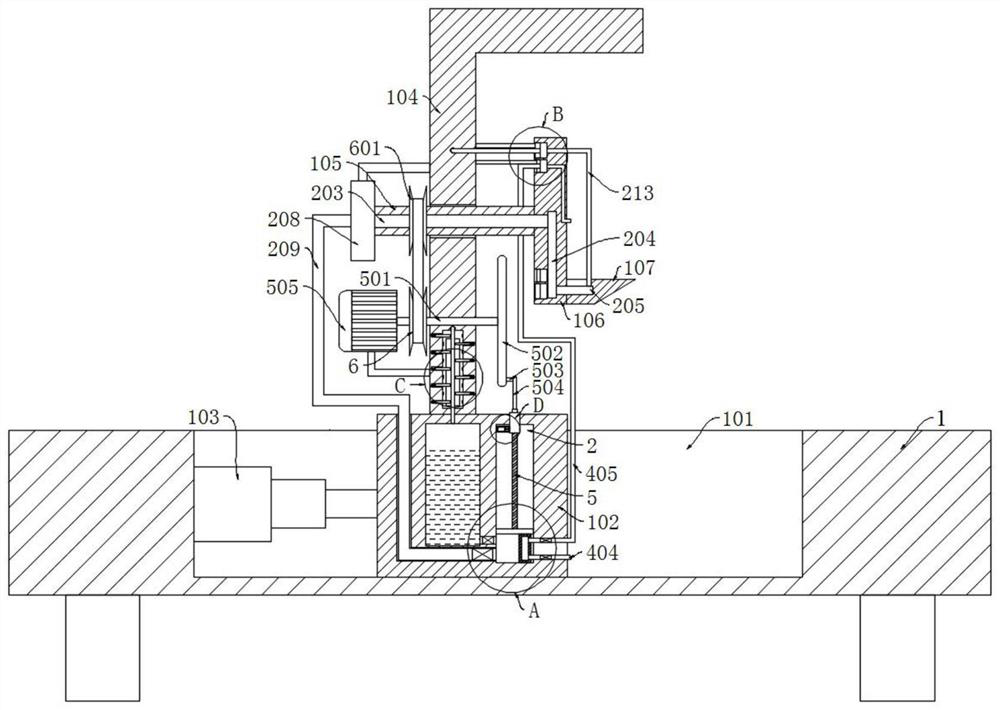

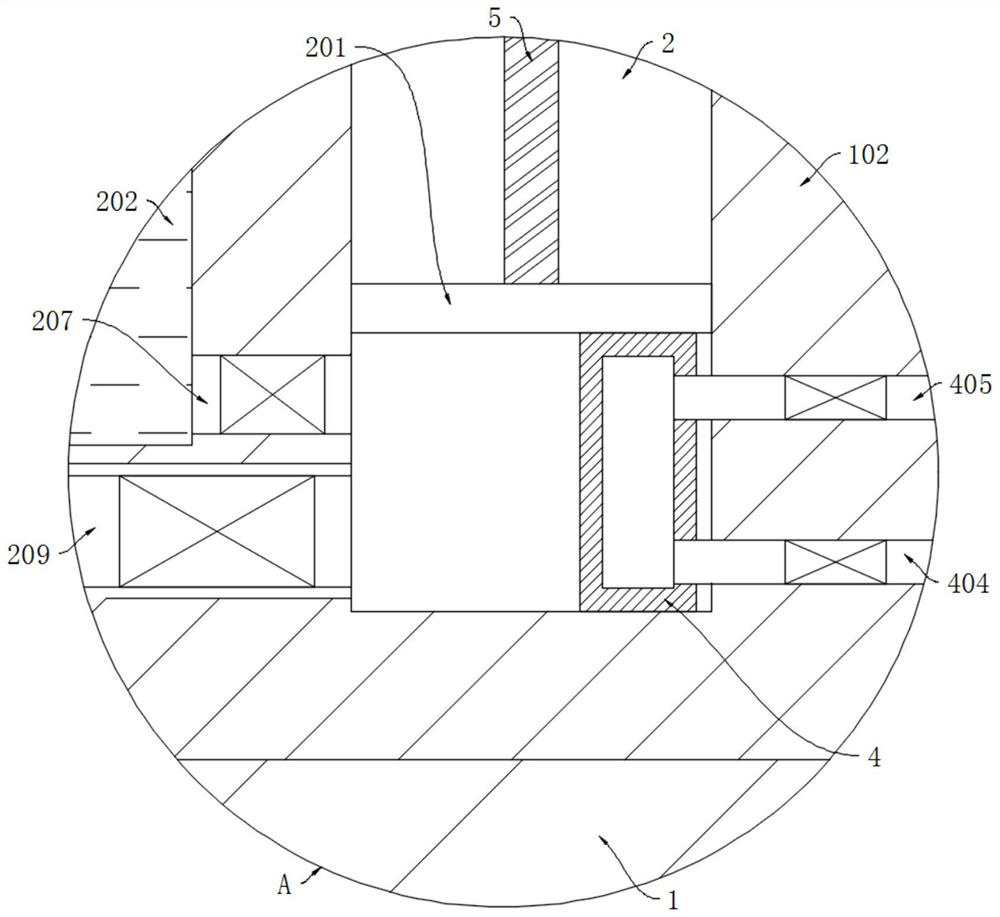

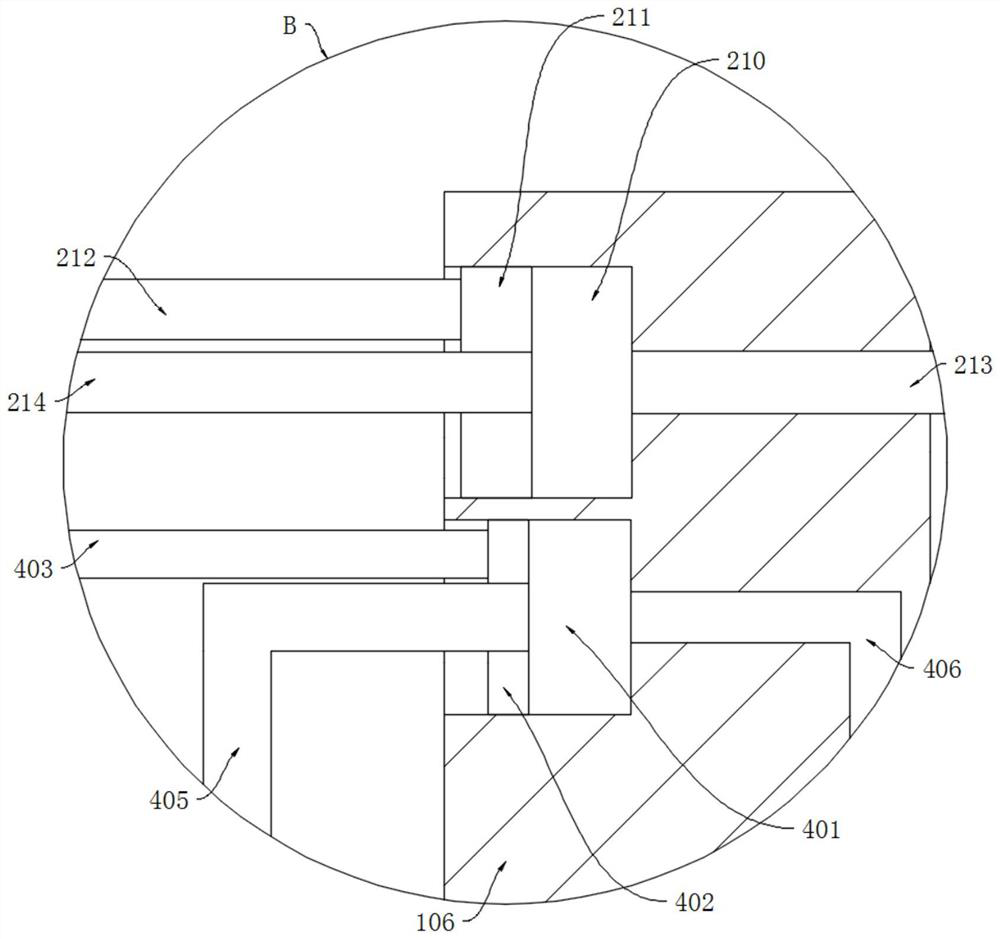

[0024] refer to Figure 1-5 , a pipe fitting chamfering machine for fitness equipment production and processing, comprising a base 1, the lower end of the base 1 is symmetrically and fixedly connected with a support column, and the lower end of the support column is fixedly connected to the ground through expansion screws, the upper end of the base 1 is provided with a chute 101, the chute The inner wall of 101 is slidably connected with a moving block 102, the inner wall of the chute 101 is fixedly connected with an electric push rod 103, the movable end of the electric push rod 103 is fixedly connected with the moving block 102, and the upper end of the moving block 102 is fixedly connected with a mounting rod 104, the mounting rod 104 is L The shape can block the debris generated during the chamfering process, and prevent the debris from flying around and causing injuries to the surrounding workers. The side wall of the mounting rod 104 is rotatably connected to the rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com