Tin-plated plate containing sunflower pattern and used for aerosol can bottom cover and production method of tin-plated plate

A production method and technology of aerosol cans, which are applied in the field of tinplate for the bottom cover of aerosol cans, can solve the problem of no sunflower pattern and achieve the effect of improving the surface quality

Pending Publication Date: 2022-06-17

邯郸市金泰包装材料有限公司

View PDF11 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The technical problem to be solved by the present invention is to solve the above-mentioned deficiencies in the prior art, and the method

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Example Embodiment

[0058]实施例1中制备气雾罐底盖用镀锡板的其他工艺参数为S2中热轧的加热温度为1150℃,粗轧出口温度为1080℃,终轧温度为865℃,卷取温度为590℃;S3中酸洗的速度为100m / min,温度为85℃,盐酸的浓度为14%。

Example Embodiment

[0059]实施例2中制备气雾罐底盖用镀锡板的其他工艺参数为S2中热轧的加热温度为1180℃,粗轧出口温度为1090℃,终轧温度为875℃,卷取温度为600℃;S3中酸洗的速度为106m / min,温度为88℃,盐酸的浓度为16%。

Example Embodiment

[0060]实施例3中制备气雾罐底盖用镀锡板的其他工艺参数为S2中热轧的加热温度为1220℃,粗轧出口温度为1110℃,终轧温度为885℃,卷取温度为610℃;S3中酸洗的速度为113m / min,温度为92℃,盐酸的浓度为18%。

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

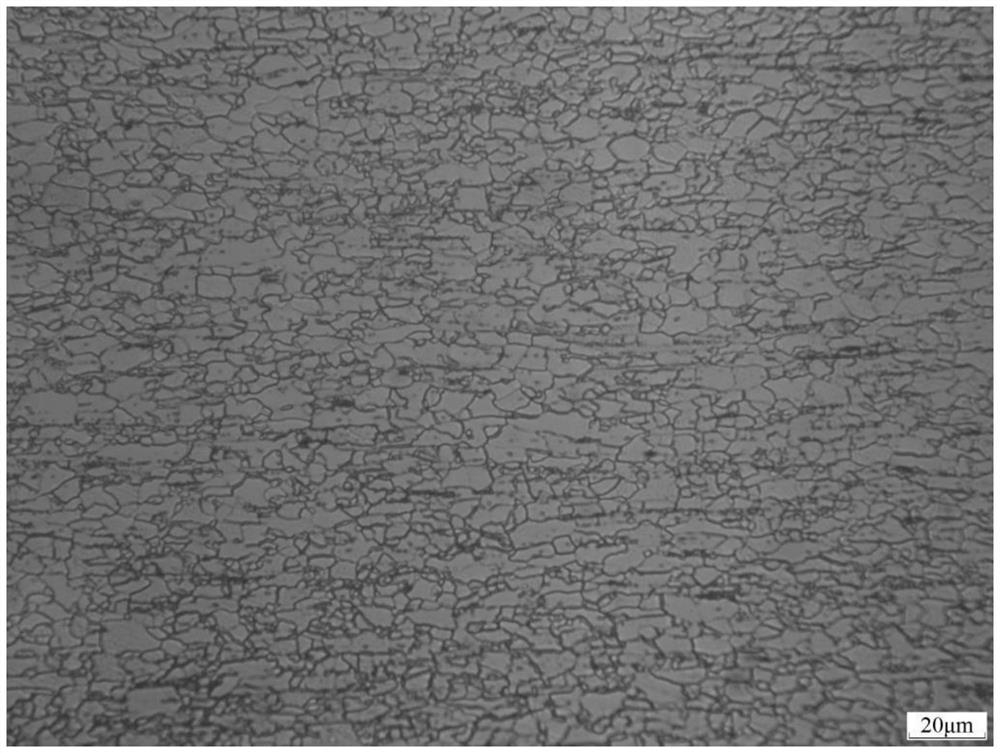

The invention provides a sunflower pattern-containing tin plate for an aerosol can bottom cover. The sunflower pattern-containing tin plate comprises the following chemical components in percentage by mass: 0.06%-0.10% of C, 0.45%-0.55% of Mn, 0.02%-0.06% of Als, less than or equal to 0.03% of Si, less than or equal to 0.015% of P, less than or equal to 0.02% of S, less than or equal to 0.005% of N and the balance of iron and inevitable impurities. The invention further provides a production method of the tinned plate containing the sunflower pattern for the aerosol can bottom cover. The production method comprises the procedures of steelmaking, hot rolling, acid pickling, cold rolling, continuous annealing, flattening and tinning. After the tin-plated plate for the aerosol can bottom cover produced by the method is formed, sunflower patterns are formed on the surface.

Description

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C38/04C22C38/06C25D3/30C25D7/06B21C37/04C21D8/02C22C38/00C22C38/02

CPCC22C38/04C22C38/06C22C38/02C22C38/001B21C37/04C21D8/0205C21D8/0226C21D8/0236C21D8/0247C21D8/0278C25D7/0614C25D3/30

Inventor 景锋李建设景振果谢红印苗素静申李焱韩刚王朋飞郝丽霞张鋆慧侯晓叶赵冬司永强

Owner 邯郸市金泰包装材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com