Environment-friendly water-jet loom wastewater recycling device

A technology of water jet loom and waste water recycling, applied in separation methods, filtration separation, chemical instruments and methods, etc., can solve the problem of inability to squeeze, increase the effective contact area between waste water and the side wall of the water filter cartridge, and fail to reduce the collection load and other problems to achieve the effect of convenient filtration and purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

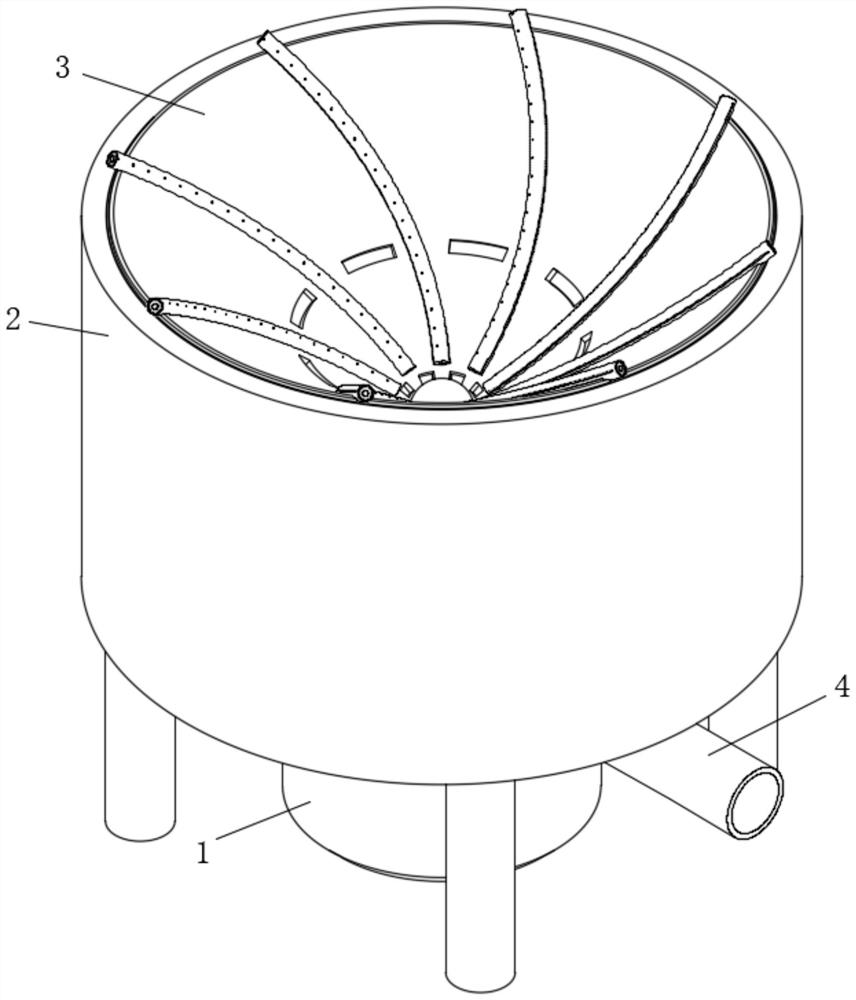

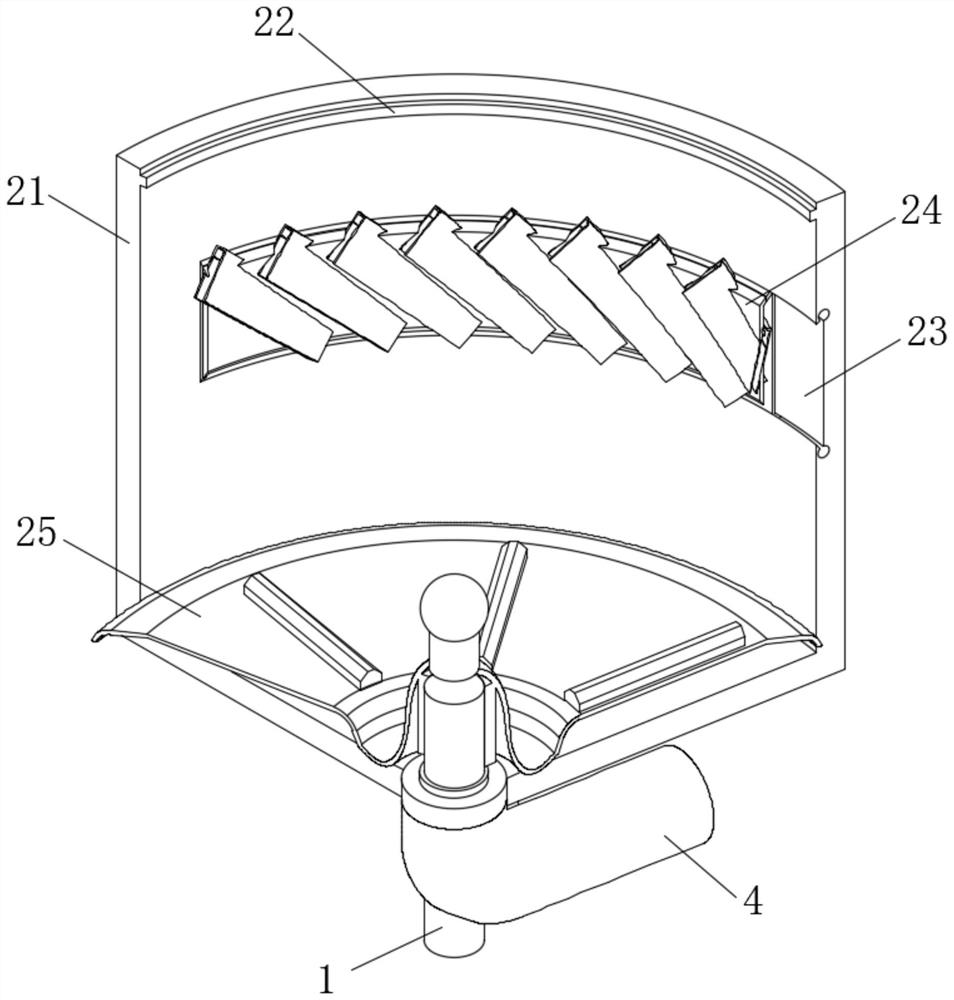

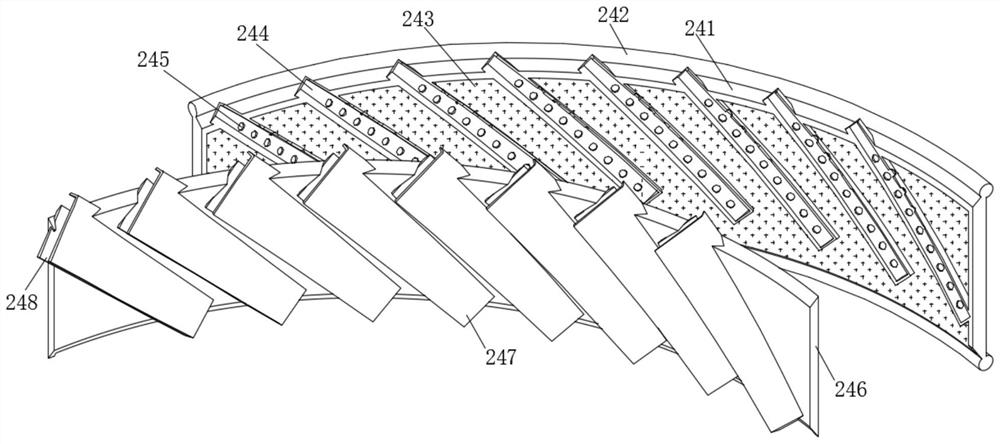

Embodiment 1

[0031] like Figure 1-Figure 6 As shown, the present invention provides a technical solution: comprising a motor 1, a waste water cylinder assembly 2 is installed on the upper end surface of the motor 1, a rotary bucket mechanism 3 is movably installed at the inner middle position of the waste water cylinder assembly 2, and a lower end surface of the waste water cylinder assembly 2 is installed. The middle position is fixedly connected with a return pipe 4 for recycling waste water; the waste water cartridge assembly 2 includes a water filter cartridge 21, and a water blocking ring 22 is fixedly connected to the inner side wall surface of the water filter cartridge 21 near the upper end side, and the water filter cartridge 21 The middle position of the inner side wall surface is provided with a wall clip slot 23, the inner side of the wall clip slot 23 is installed with a cover net mechanism 24, and the cover net mechanism 24 is fitted and installed with the water filter cartri...

Embodiment 2

[0036] like Figure 4-Figure 5 As shown, the rotating bucket mechanism 3 includes a water rotating bucket 31, the inner side wall surface of the water rotating bucket 31 is provided with a water leakage window 32 in a circular array, and the inner side wall surface of the water rotating bucket 31 is provided with a spiral groove 33 in a circular array. A top wall cover 34 is fixedly connected to the lower end surface of the water spinner 31; a spiral wall tube 35 is installed on the inner side of the spiral groove 33, and a drawing assembly 36 is installed on the inner side of the spiral wall tube 35, and the spiral wall tube 35 passes through the spiral groove 33. The water bucket 31 is fitted and installed, the water swirl bucket 31 is movably installed with the water filter cartridge 21 through the water blocking ring 22, and the water swirl bucket 31 is rotatably installed with the water stirring plate 251 through the top wall cover 34 and the dome ball 253; the spiral wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com