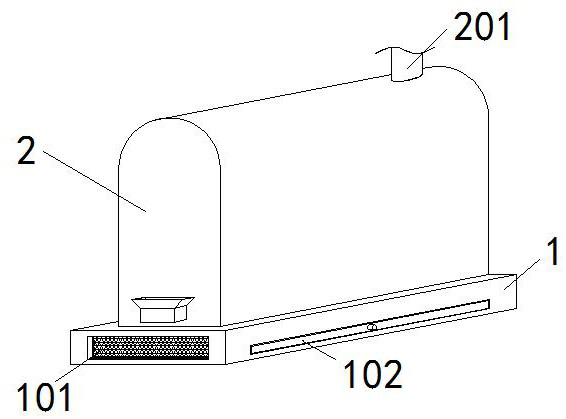

Comprehensive air inlet device of household garbage incinerator

A technology of domestic waste incineration and air intake device, which is applied in the direction of incinerator, combustion type, combustion method, etc., to achieve good combustion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] When the air guide tooth 307 enters the air guide groove 317 at the bottom of the retaining wall 302, the opening and closing door 309 in the bottom of the air guide groove 317 will be pushed back, and the top column 310 at the bottom will be opened after the opening and closing door 309 is fully opened and closed. The airtight door 308 at the top of the air guide tooth 307 is pushed open, and the air will enter the inside of the retaining wall 302 through the air guide tooth 307 at this time.

[0032] Embodiment three:

[0033] When the air deflector 311 moves upward, the connecting column 315 will be used to drive the combustion-supporting plate 314 to move upward along the movable groove 312 .

Embodiment 2

[0035]When the combustion-supporting plate 314 moves to the top of the movable groove 312, the material dial column 318 on the top of the combustion-supporting plate 314 will protrude through the hole in the combustion net 313, and the raw material will be pushed and exchanged so that the raw material can be fully burned, and the combustion-supporting plate 314 will The one-way valve 318 on the board is opened, and the dust collected on the board is introduced into the collection drawer 4 .

[0036] Embodiment five:

[0037] When the combustion-supporting plate 314 moved to the bottom of the movable groove 312, the one-way valve 318 on the plate was closed, so that the flame-retardant plate 314 formed a sealed plate, and the ashes on the conveyor belt 301 were sucked on the conveyor belt 301 by the holes in the combustion net 313. Burner plate 314.

Embodiment 3

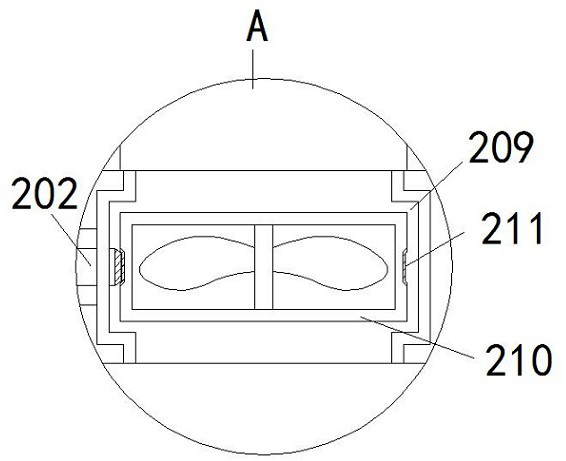

[0039] When the transmission shaft 106 rotates, it will drive the drive shaft 305 to rotate and make the conveyor belt 301 meshed with it rotate. At this time, the drive shaft 305 will input air into the interior through the transmission shaft 106, and the imported air will enter the air guide teeth 307. When the guide When the gas tooth 307 enters the air guide groove 317 at the bottom of the retaining wall 302, the opening and closing door 309 in the bottom of the air guiding groove 317 will be pushed back, and the top column 310 at the bottom will guide the air after the opening and closing door 309 is fully opened and closed. The airtight door 308 on the top of the teeth 307 is pushed back, and now the air will enter the inside of the retaining wall 302 through the air guide teeth 307 and blow up the air deflector 311 to guide the air out of the surface of the conveyor belt 301 so that the raw materials can be fully burned.

[0040] When the air deflector 311 moves upwards,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com