Broken line detection system and method

A technology of wire breakage detection and detection device, which is applied to wire breakage detectors, textiles, papermaking, sewing equipment, etc., to achieve the effect of high detection accuracy and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

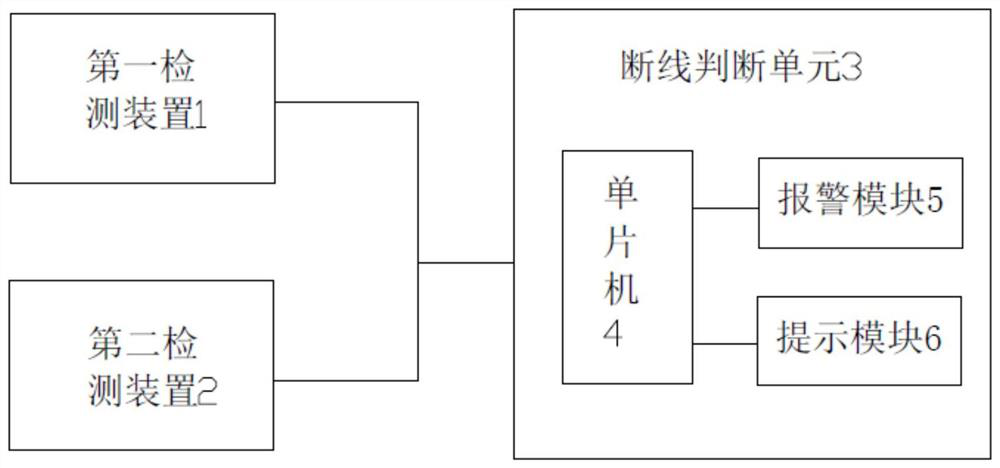

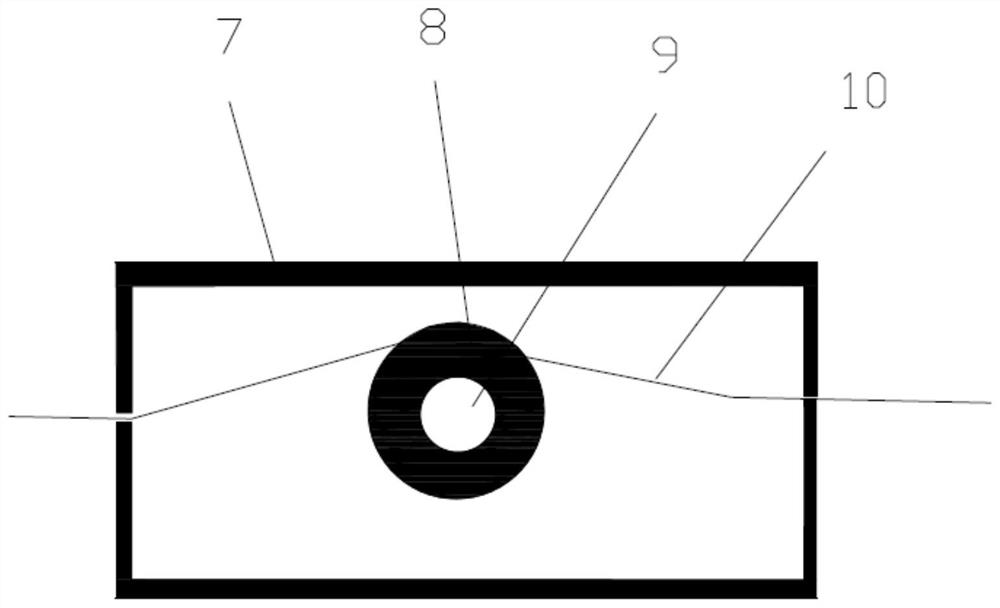

Method used

Image

Examples

Embodiment 1

[0030] The present invention also provides a disconnection detection method, comprising the following steps:

[0031] Embodiment two:

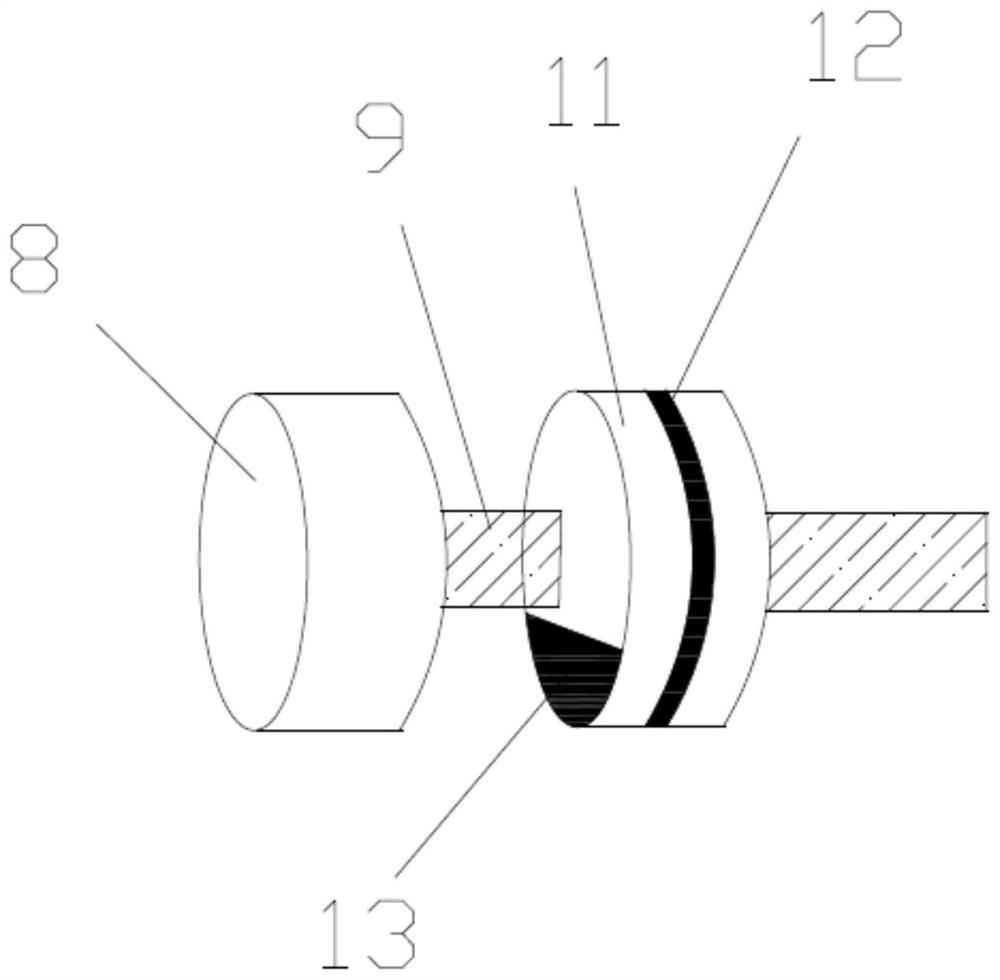

[0032] The needle suture passes through the first through hole of the base body, the second through hole of the first electrode plate and the third through hole of the second capacitor plate, and when the needle reciprocates up and down, it drives the needle suture to move up and down , the sewing thread of the machine needle is connected with the second through hole, the friction force is generated when the thread is hooked, and the generated friction force overcomes the elastic force and does work to drive the first plate to move downward, so that the capacitance value changes. When the thread is taken up, the spring force By doing work, the first capacitor plate is far away from the second capacitor plate, and the capacitance value further changes, and then a signal pulse is generated to realize the broken thread detection of the needle sut...

Embodiment 2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com