Double-roller crusher for mine

A roll crusher, mining technology, applied in the direction of solid separation, chemical instruments and methods, grain processing, etc., to achieve the effect of improving crushing efficiency, preventing clogging, and improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

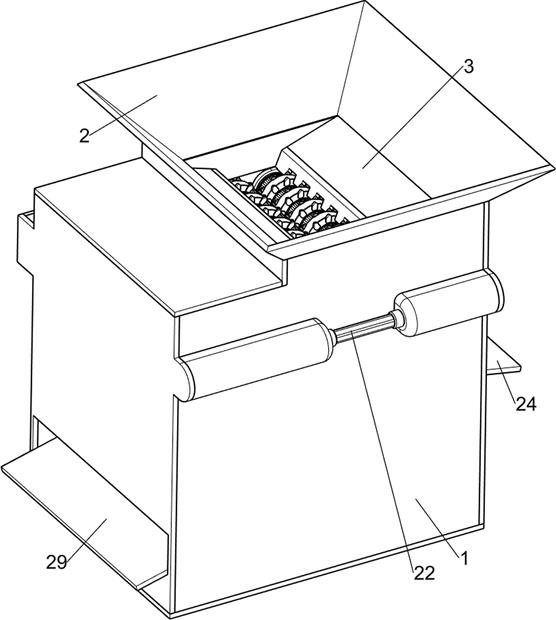

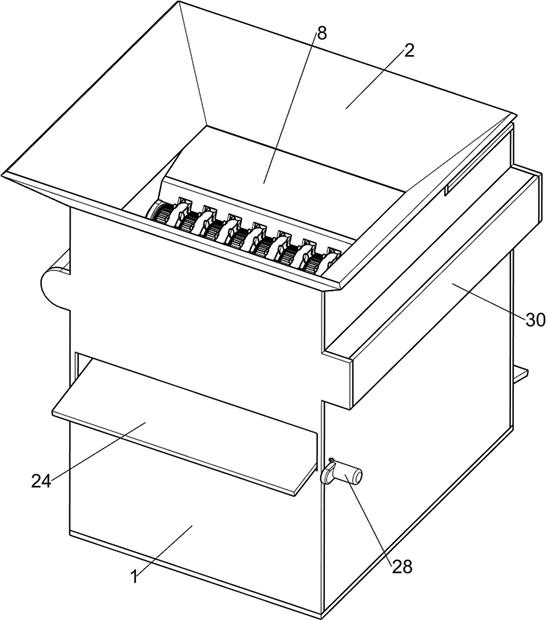

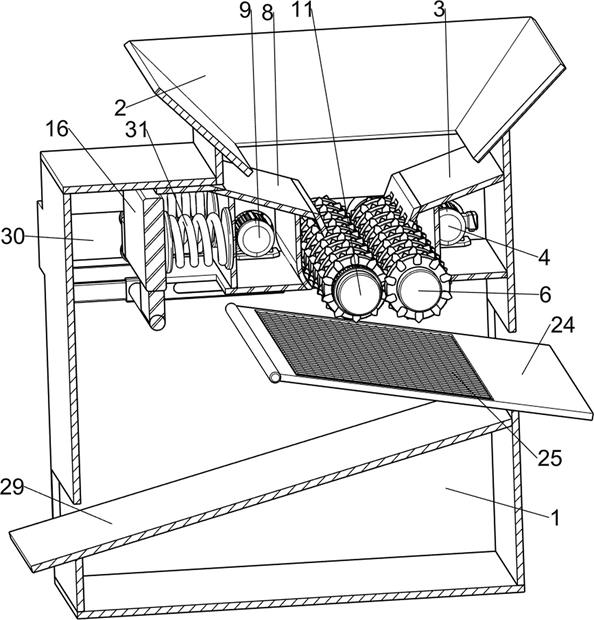

[0035] Hereinafter, a pair-roll crusher for mines according to an embodiment of the present invention will be described with reference to the accompanying drawings, such as figure 1 - Figure 10 As shown, the mine roller crusher includes a shell 1, a funnel 2, a crushing device capable of crushing mineral materials, an elastic device capable of making the crushing device avoid hard objects, an adjusting device capable of changing the size of the crushed mineral material, and a The feeding device for separating hard objects and mineral materials, the funnel 2 is fixed above the shell 1, the crushing device is set in the shell 1, the elastic device is set in the shell 1, the elastic device is located behind the crushing device, and the adjusting device is set on the side of the shell 1 , The unloading device is located in the casing 1, and the unloading device is located below the crushing device.

[0036] like image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7As s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com