Bearing capacity calibration method of dynamic pressure thrust gas bearing

A technology of gas bearing and calibration method, which is used in bearing-related force sensors, mechanical bearing testing, force/torque/work measuring instruments, etc., to achieve the effect of quick calibration process and comprehensive calibration data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

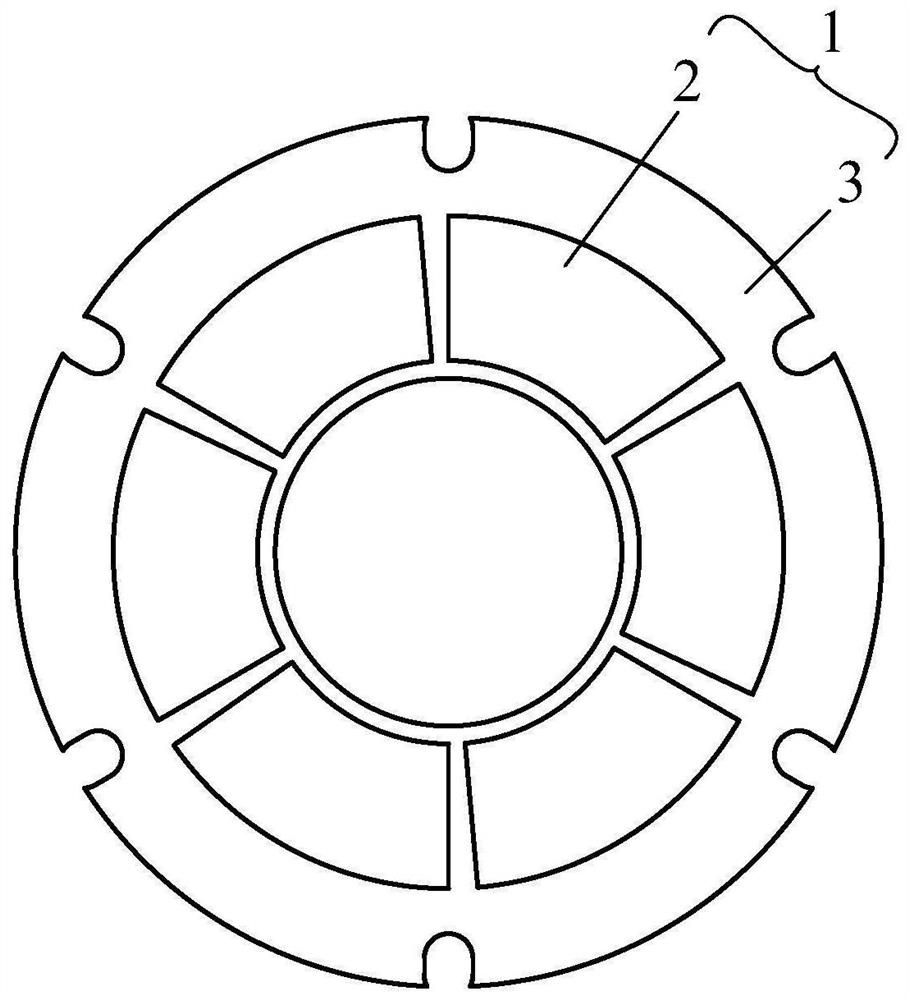

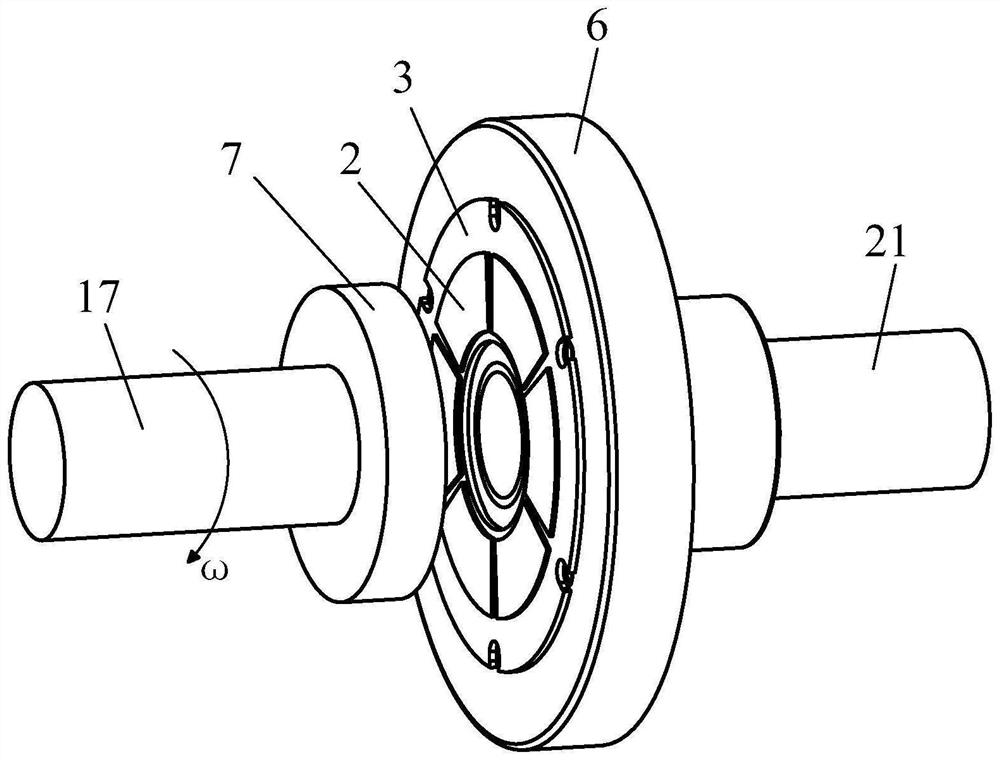

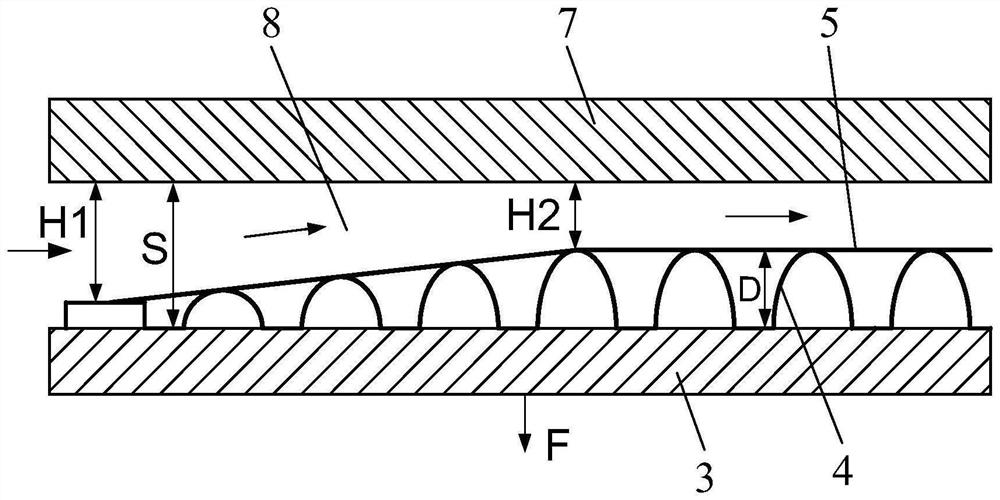

[0038] The embodiment of the present invention provides a bearing capacity calibration method of a dynamic pressure thrust gas bearing 1, and the bearing capacity calibration method adopts a bearing capacity calibration system to realize the bearing capacity calibration, such as Figure 7 As shown, the bearing capacity calibration method specifically includes the following steps:

[0039] The first step is to start the bearing capacity calibration system: install the dynamic pressure thrust gas bearing 1 to be calibrated, turn on the power supply, make all parts of the bearing capacity calibration system energize and start, and set the load of the load application device 11 to zero, The rotor driving device 10 is set as the initial speed, and the initial speed can be determined according to the actual situation, such as: the initial calibration speed ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com