Composite material patching method for long-section casing damage well

A composite material and composite material belt technology, which is applied in the fields of earth-moving drilling, wellbore/well components, climate sustainability, etc., can solve the problems of complex operation procedures and processes, and achieve the effect of high deformation strength and reduced outer diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

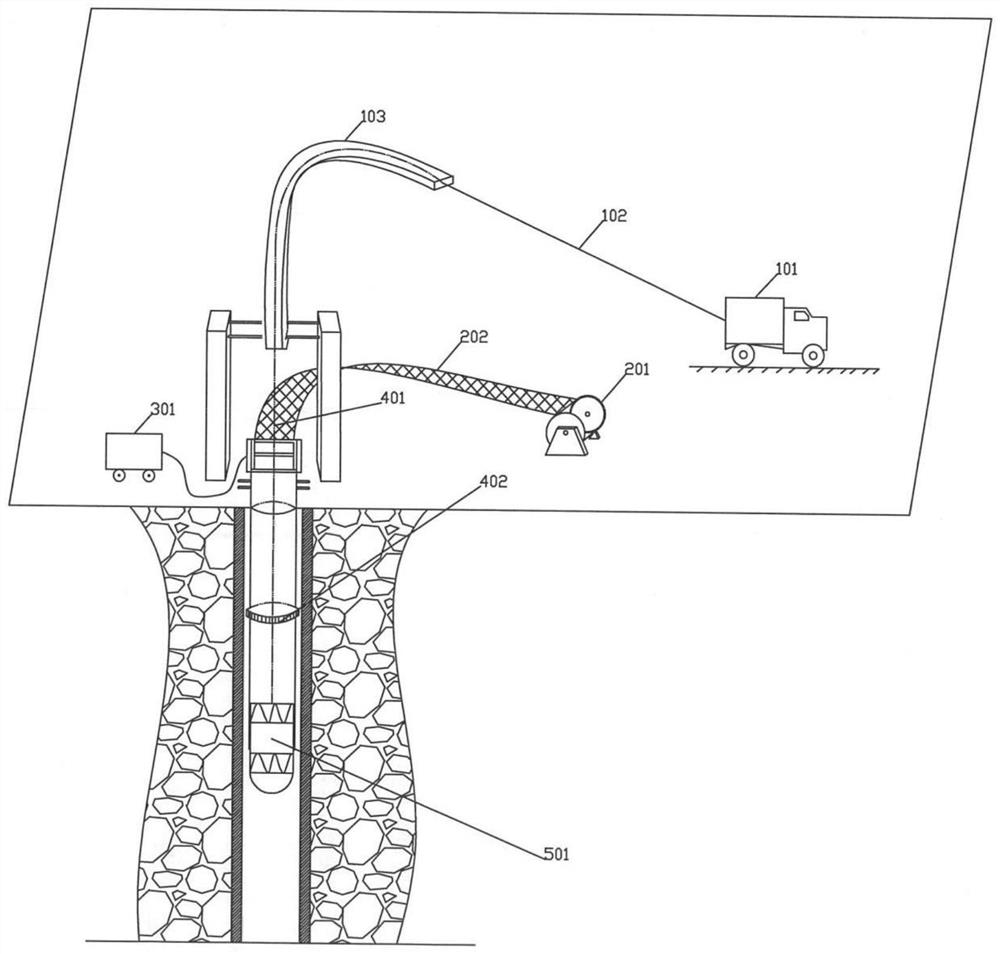

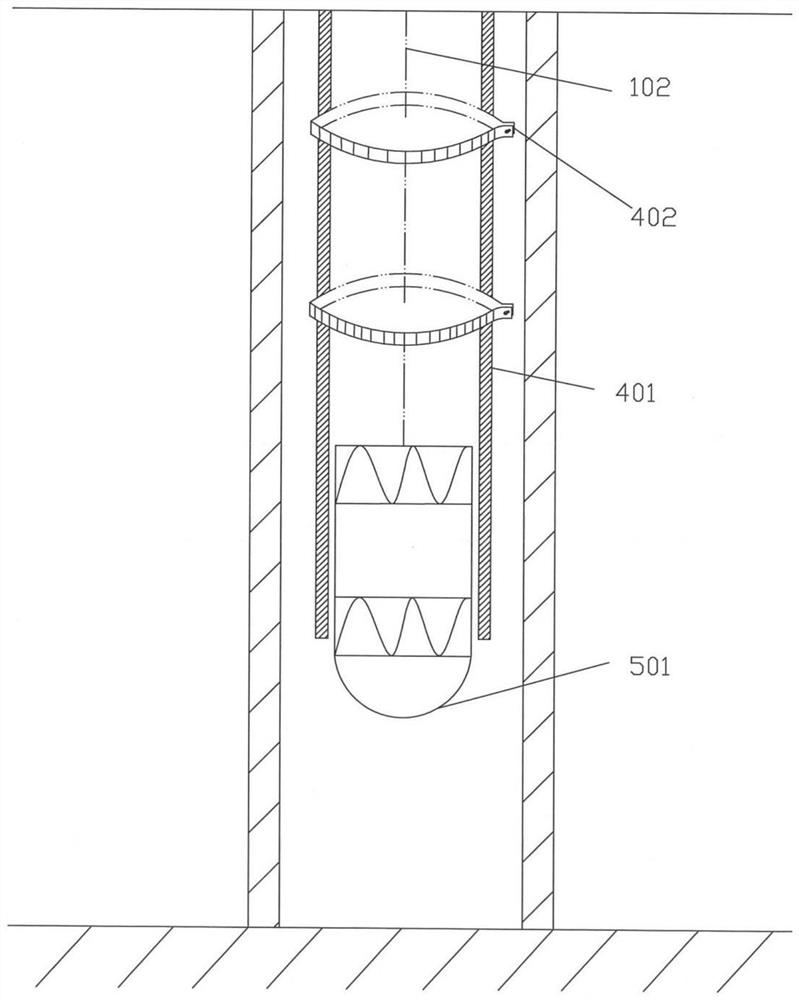

[0073] In this example, a composite material subsidy method for a long casing damaged well is implemented in Well X-3. The depth of Well X-3 is 1883 m, the casing specification outer diameter × wall thickness = 139.7 mm × 7.72 mm, and the casing damage location is at 1051-1059m, the well temperature of the casing damaged section is about 40°C, the operation schematic diagram of the composite material subsidy method for the long casing damaged well is as follows figure 1 and Figure 5 shown, from figure 1 and Figure 5 It can be seen that it includes the following specific steps:

[0074] According to the casing specification, well temperature, casing damage and other working conditions, determine the casing subsidy process parameters:

[0075] According to the damage position of the casing 1051-1059m, the length of the subsidy pipe is 10m and the thickness is 3mm;

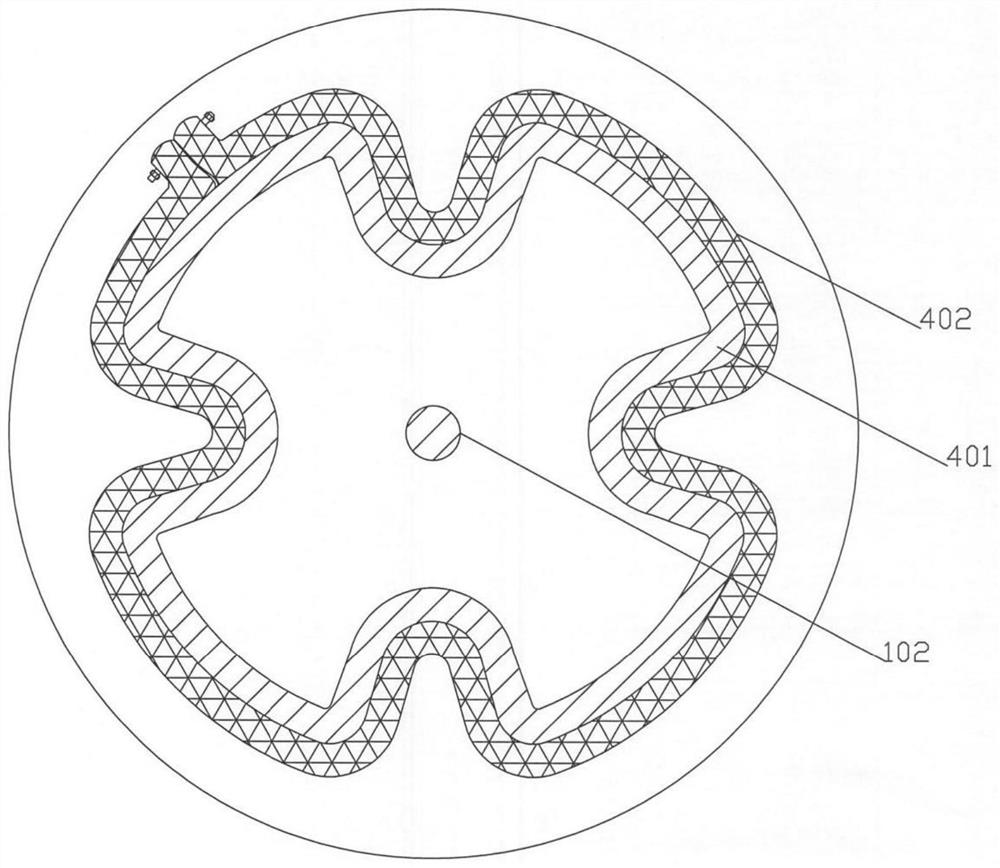

[0076] According to the outer diameter of the casing × wall thickness = 139.7 mm × 7.72 mm, the circumferenc...

Embodiment 2

[0088] In this example, a composite material subsidy method for a long casing damaged well is implemented in Well Y-3. The depth of Well Y-3 is 2208 m, the casing specification outer diameter × wall thickness = 139.7 mm × 9.17 mm, and the casing damage location is at 1420-1580m, the well temperature of the casing damaged section is about 55°C, and the composite material subsidy method for the long casing damaged well specifically includes the following steps:

[0089] According to the casing specification, well temperature, casing damage and other working conditions, determine the casing subsidy process parameters:

[0090] According to the damage position of the casing 1420-1580m, the length of the subsidy pipe is 180m and the thickness is 4mm;

[0091] According to the outer diameter of the casing × wall thickness = 139.7 mm × 9.17 mm, the circumference of the inner wall of the casing is calculated to be 381 mm, and the lateral width of the PTFE sheet is determined to be 400...

Embodiment 3

[0103] In this example, the composite material subsidy method for long casing damaged wells is implemented in Well JY-3. The depth of Well JY-3 is 2208 m, the outer diameter of casing specification × wall thickness = 139.7 mm × 9.17 mm, and the damage position of casing is at 1433-1593m, the well temperature of the casing damaged section is about 55℃;

[0104] The only difference between this example and Example 2 is that the composite material tape used in this example is made of bismaleimide shape memory polymer and carbon fiber reinforced material by molding and curing, and the bismaleimide shape memory The glass transition temperature of the polymer is 95-123°C, the deformation temperature is 70-75°C, and the cable heating temperature is 85°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile yield strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com