Machine core and barrier gate

A technology of movement and brake lever, which is applied in the field of barrier gates, can solve problems such as complex manufacturing process, and achieve the effect of simple and fast processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

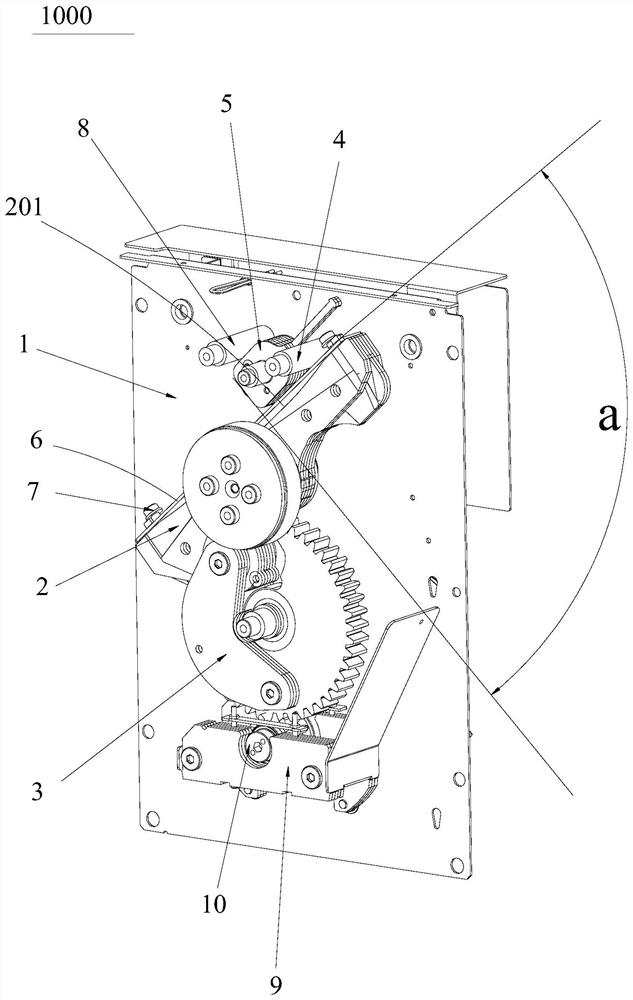

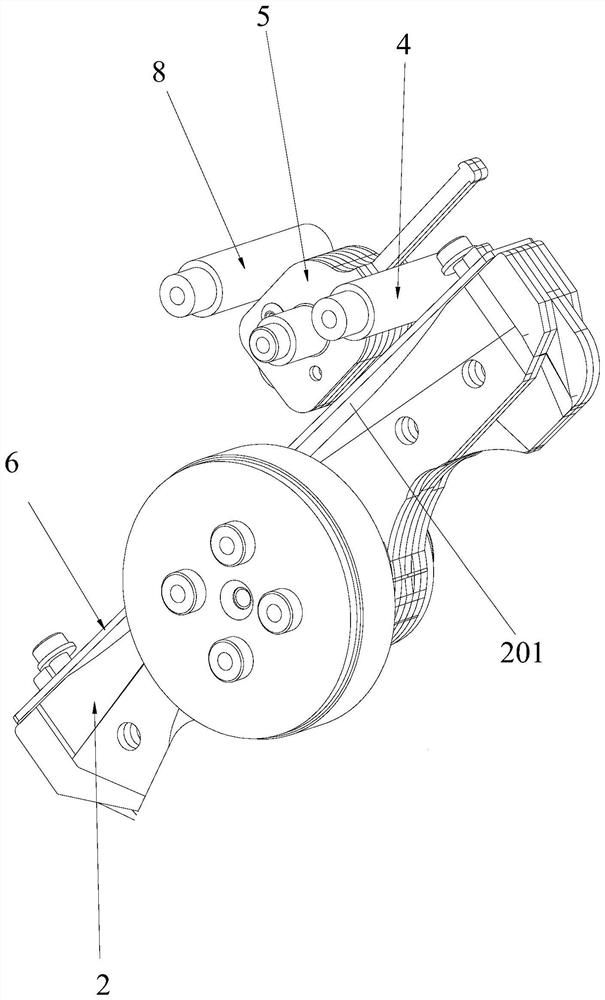

[0046] see figure 2 , as another specific embodiment of the movement 1000 provided by the present application, the lifting drive mechanism 3 also includes a turret 9 installed on the mounting plate 1 (connected by bolts and other components, and forms a certain gap); A turning hole 101 is opened, and the output shaft 3011 passes through the turning hole 101 and is mounted on the turret 9 for rotation. The gap between the turret 9 and the mounting plate 1 is used to accommodate the output shaft 3011 and the driving gear 302 on the output shaft 3011, and the output When the shaft 3011 rotates, the rotation hole 101 and the turret 9 are used as the base of rotation to improve the stability of the rotation; the opposite sides of the driven gear 303 are provided with connecting rods 304, and the connecting rods 304 on both sides are also respectively Rotately connected with both sides of the swing member 2, part of the driven gear 303 is inserted between the connecting rods 304 on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com