Temperature change type anti-counterfeiting paperboard and production process thereof

A production process, temperature-variable technology, applied in special paper, anti-biological reagent addition, papermaking, etc., can solve the problems of no anti-counterfeiting performance, limited application scope, shortened service life, etc. The effect of broadening application fields and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

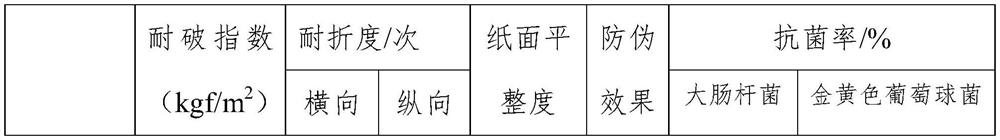

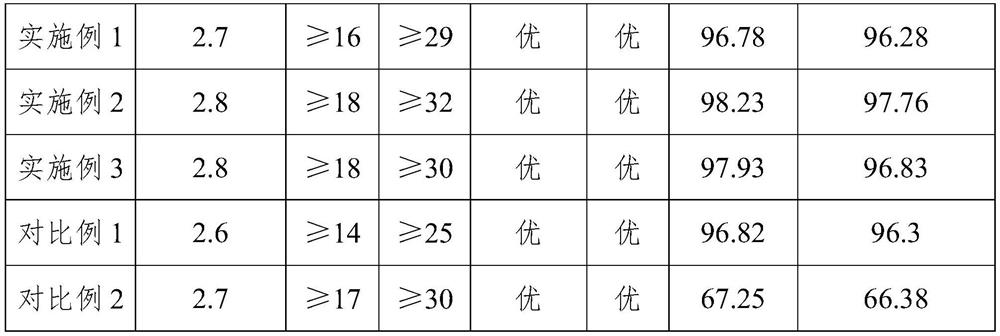

Embodiment 1

[0034] A kind of temperature-changing anti-counterfeiting cardboard, the temperature-changing anti-counterfeiting cardboard includes the anti-counterfeiting base layer, the core paper layer and the anti-counterfeiting surface paper layer from bottom to top;

[0035] The slurry used in the anti-counterfeiting substrate layer is composed of 65wt% hardwood pulp and a residual amount of softwood chemical sulfate pulp;

[0036] The slurry used in the core paper layer is composed of 55% maple chemical mechanical pulp and the residual birch chemical mechanical pulp;

[0037] The slurry used in the security paper layer consists of 20% softwood chemical sulfate slurry and a residual eucalyptus chemical mechanical slurry.

[0038] The security paper layer is quantitatively 27g / m 2 The anti-counterfeiting substrate layer is quantitatively 26g / m 2 。

[0039] A production process for temperature-variable anti-counterfeiting cardboard consisting of the following steps:

[0040] Step 1: Mix the ...

Embodiment 2

[0057] The production process of the temperature-changing anti-counterfeiting cardboard is roughly similar to the technical solution provided in Example 1, the main differences between the two are as follows:

[0058] The slurry used in the anti-counterfeiting bottom layer is composed of 75wt% hardwood pulp and a residual amount of softwood chemical sulfate pulp;

[0059] The slurry used in the core paper layer is composed of 65% maple chemical mechanical pulp and a residual birch chemical mechanical pulp;

[0060] The slurry used in the security paper layer consists of 25% softwood chemical sulfate slurry and a residual eucalyptus chemical mechanical slurry.

[0061] The security paper layer is quantitatively 30g / m 2 The anti-counterfeiting substrate layer is quantitatively 28g / m 2 。

[0062] The amount of warm fiber used is 2.0% of the total mass of the mixed slurry in the pulper of step 1 and step 2, and the mass concentration of the pulp after the crushing treatment in step 1 ...

Embodiment 3

[0074] The production process of the temperature-changing anti-counterfeiting cardboard is roughly similar to the technical solution provided in Example 1, the main differences between the two are as follows:

[0075] The slurry used in the anti-counterfeiting bottom layer is composed of 80wt% hardwood pulp and a residual amount of softwood chemical sulfate pulp;

[0076] The slurry used in the core paper layer is composed of 70% maple chemical mechanical pulp and the remaining birch chemical mechanical pulp;

[0077] The slurry used in the security paper layer consists of 30% softwood wood chemical sulfate slurry and a residual eucalyptus chemical mechanical slurry.

[0078] The security paper layer is quantitatively 32g / m 2 The anti-counterfeiting substrate layer is quantitatively 30g / m 2 。

[0079] The amount of temperature-modified fiber used is 2.5% of the total mass of the mixed slurry in the pulper of step 1 and step 2, and the mass concentration of the slurry after the crush...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com