Inner gate cutting mechanism of mold

A mold and gate technology, which is applied in the field of incision gate mechanism of molds, can solve the problems of lower efficiency of needle cutting and incision gate operation, support heads cannot be set at the same position, mold deformation, etc., and achieve smooth and accurate movements , improve work efficiency, and solve the effect of mold deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

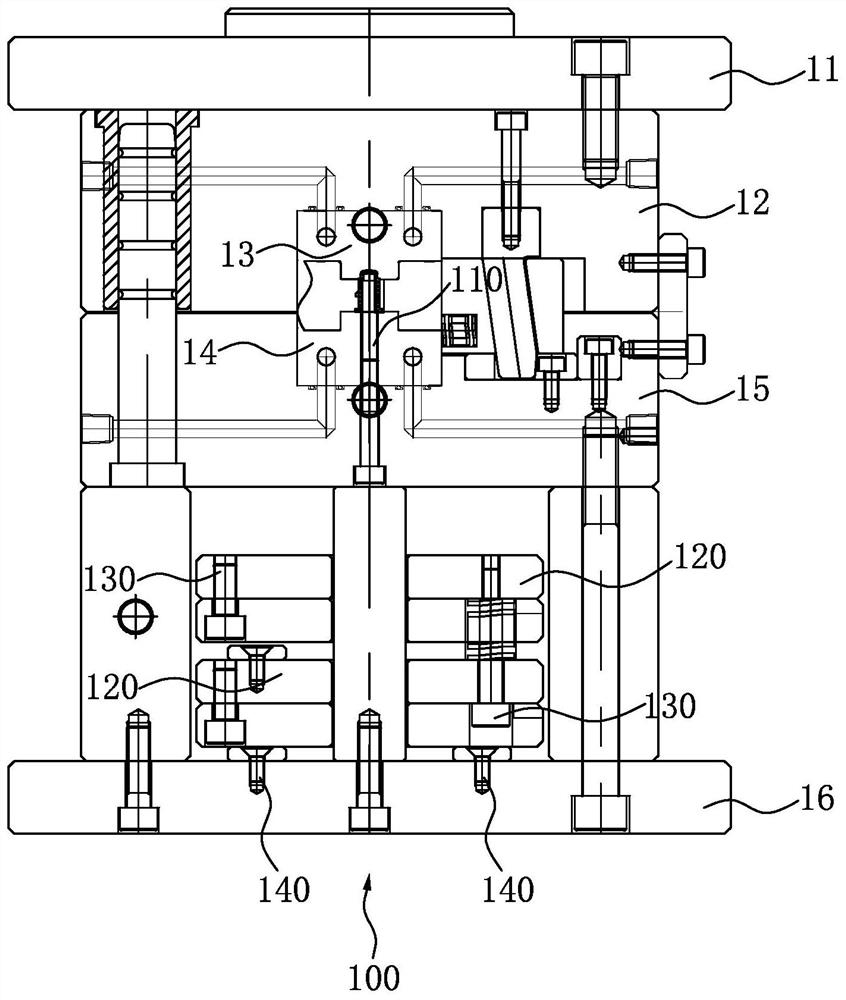

[0021] In order to further illustrate the technical means adopted by the present invention and its effects, the following is a detailed description in conjunction with a preferred embodiment of the present invention and the accompanying drawings.

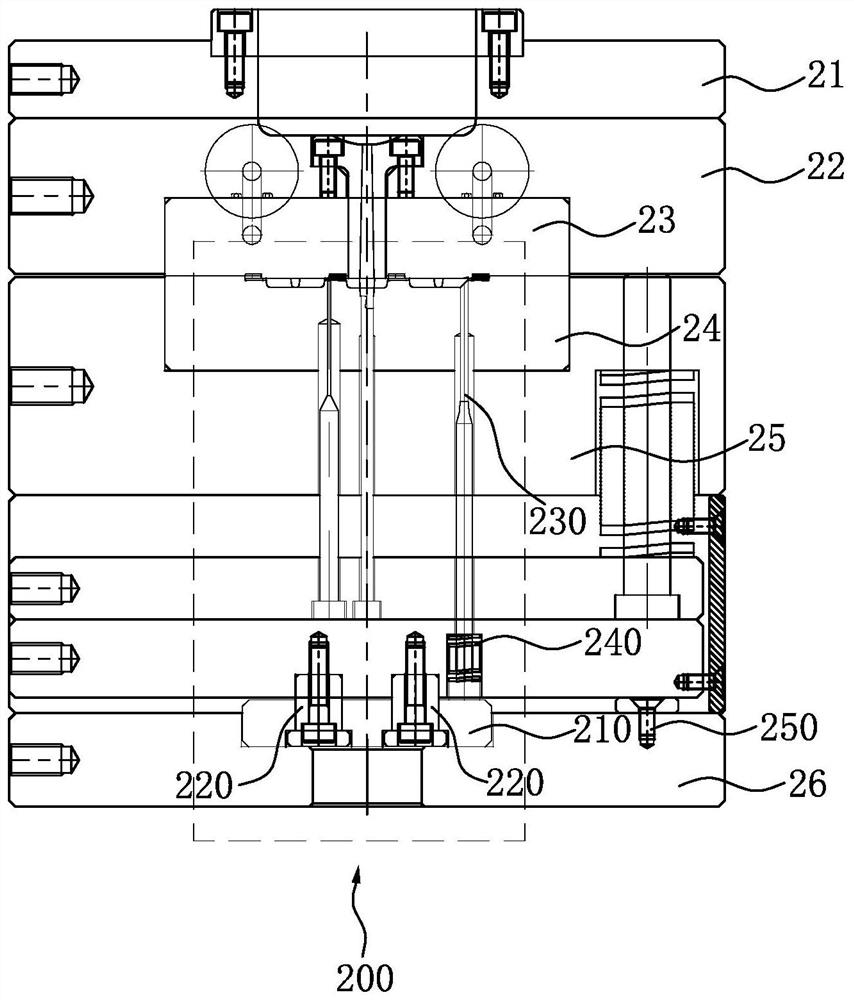

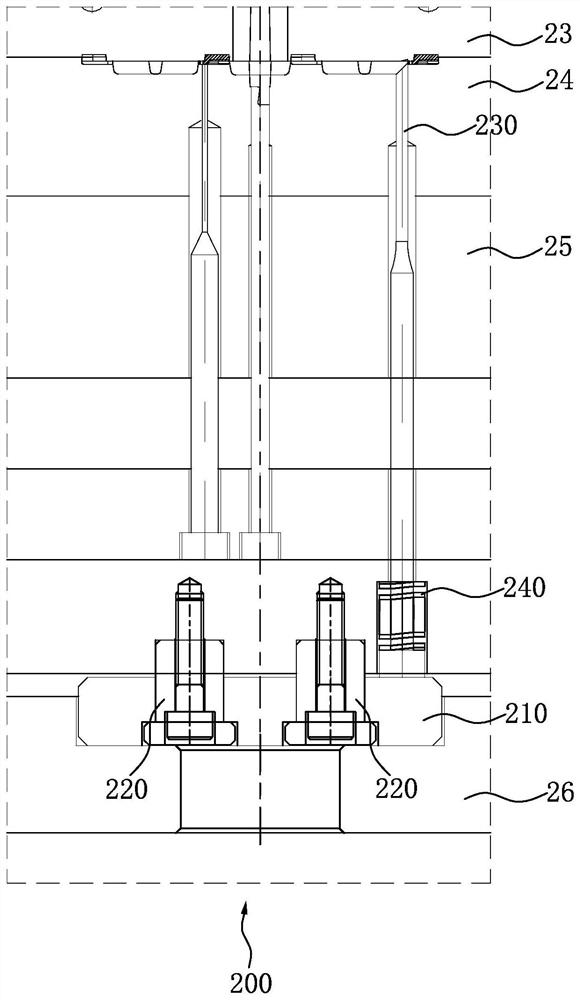

[0022] see figure 2 and image 3 shown, figure 2 is the schematic diagram of the in-cut gate mechanism of the mold of the present invention, image 3 It is a partial schematic diagram of the in-cut gate mechanism of the mold of the present invention.

[0023] The present invention provides an in-cut gate mechanism for a mold. The mold includes an upper fixed plate 21, a female template 22, a female mold core 23, a male mold core 24, a male template 25 and a lower fixed plate 26. The gate mechanism 200 includes:

[0024] an ejector plate 210, the ejector plate 210 is disposed on the lower fixing plate 26, and the ejector plate 210 is used for fixing the cutting needle 230 and the guide cylinder 220;

[0025] a guide cylinder 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com