Automatic cleaning equipment for interior of ceramic bottle

A technology for automatic cleaning and ceramic bottles, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems such as inability to clean ceramic bottles, achieve a wide range of applications, facilitate high-pressure washing, and reduce the number of settings Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will now be further described with reference to the accompanying drawings and specific embodiments.

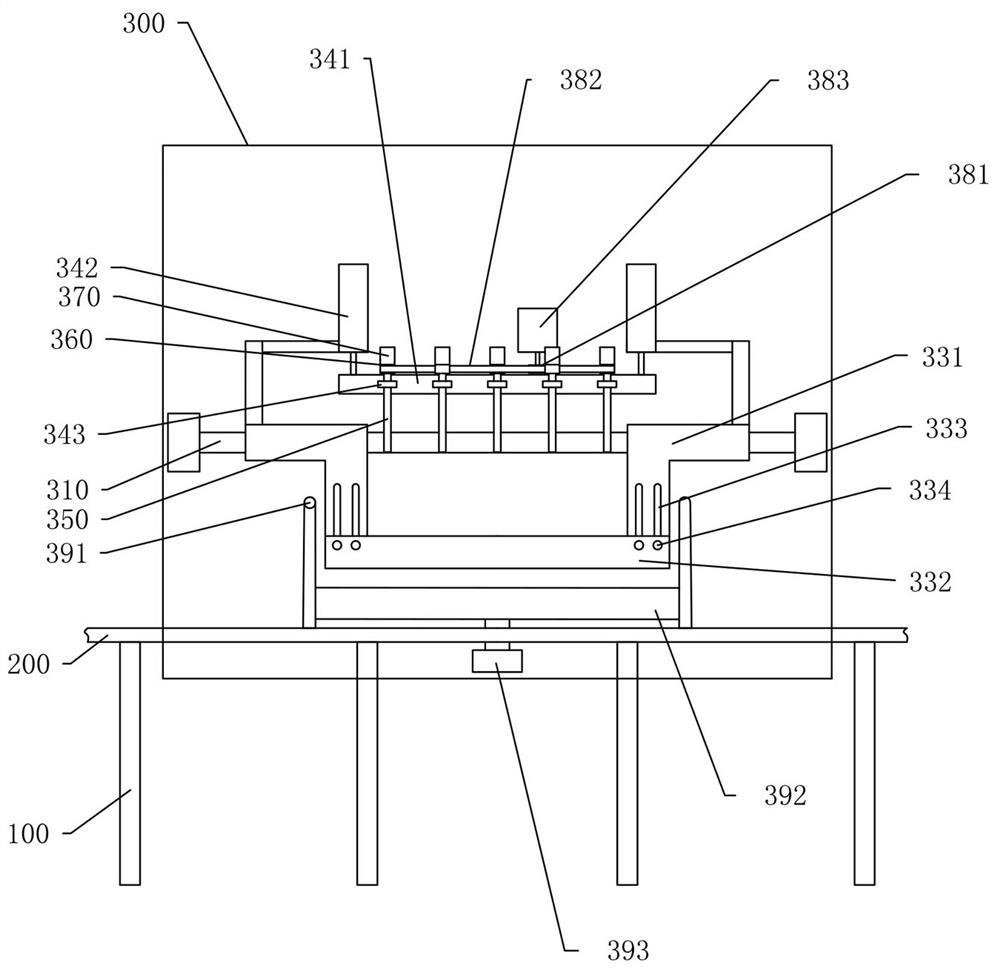

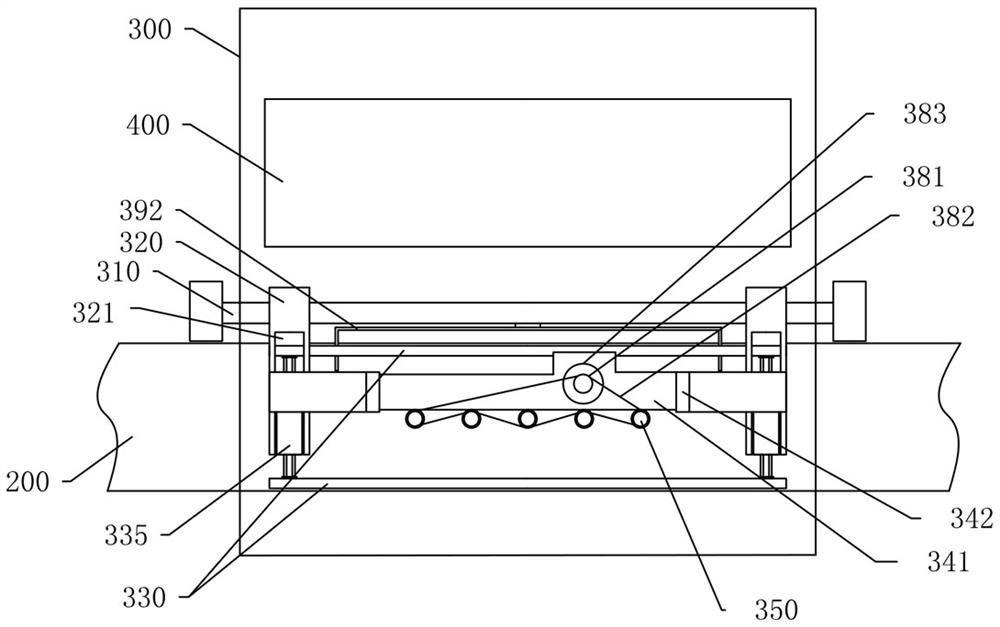

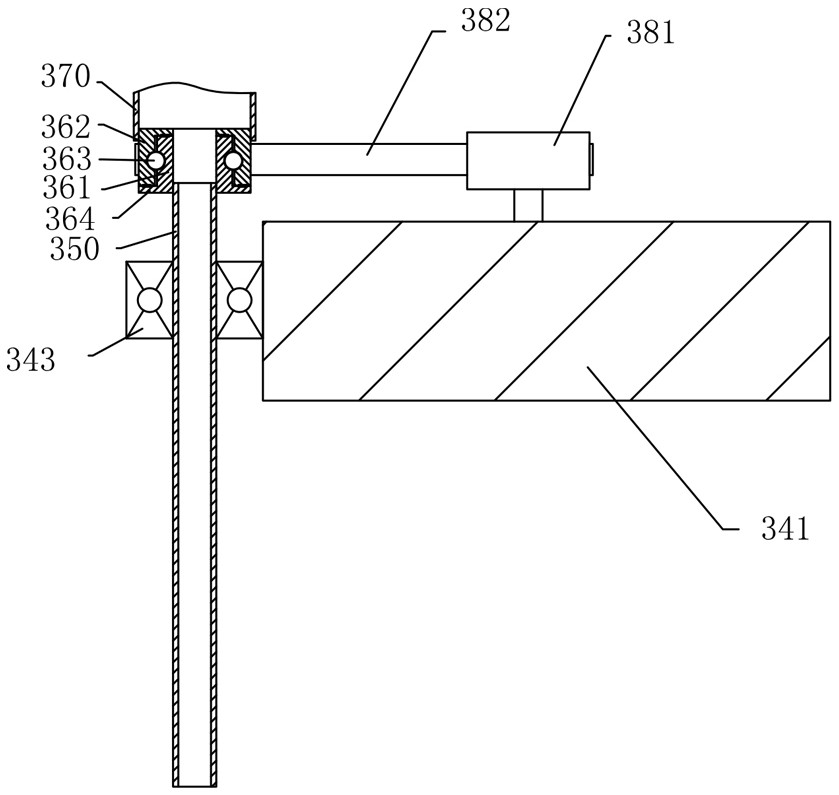

[0022] refer to Figure 1 to Figure 5 , this embodiment provides an automatic cleaning device for the interior of a ceramic bottle, including a rack 100, a conveyor belt 200 arranged on the rack 100, and a cleaning host 300 covered on part of the conveyor belt 200. The conveying direction of the conveyor belt 200 is Transversely, the cleaning host 300 is provided with a main shaft 310 parallel to the conveyor belt 200 above one side of the conveyor belt 200 , the main shaft 310 is controlled by a rotating motor and can reciprocate and rotate 180°, and the main shaft 310 is fixed on the main shaft 310 . There are two mounting racks 320, between the two mounting racks 320 there is a clamping rack 330 for clamping the products on the conveyor belt 200, and the two clamping racks 330 are driven by a bidirectional synchronous cylinder 335. Specifically,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com