Lithium ion battery

A lithium-ion battery, lithium salt technology, applied in secondary batteries, secondary battery repair/maintenance, circuits, etc., can solve problems such as insufficient safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

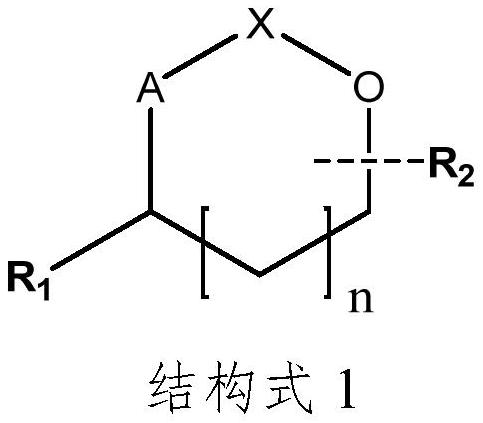

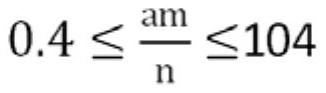

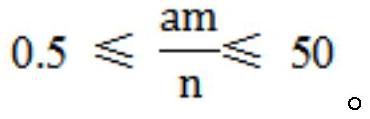

Method used

Image

Examples

Embodiment 1

[0118] This embodiment is used to illustrate the lithium ion battery disclosed in the present invention and the preparation method thereof, including the following operation steps:

[0119] 1) Preparation of positive electrode sheet

[0120] The cathode active material LiCoO 2 , conductive carbon black and binder PVDF are dispersed in non-aqueous organic solvent NMP (N-methyl-2-pyrrolidone) and mixed evenly to obtain positive electrode slurry; the positive electrode slurry is uniformly coated on the positive electrode current collector aluminum foil, After drying, rolling and cutting, a positive electrode sheet is obtained, and the weight ratio of the positive electrode active material, the conductive carbon black and the binder PVDF is 96:2:2.

[0121] 2) Preparation of negative pole piece

[0122] Disperse the negative electrode active material graphite, conductive agent, CMC and SBR in deionized water in a weight ratio of 96:1:1:2 and stir to obtain a negative electrode s...

Embodiment 2~37

[0130] Examples 2 to 37 are used to illustrate the lithium ion battery disclosed in the present invention and the preparation method thereof, including most of the operation steps in Example 1, and the differences are:

[0131] The compaction density of the negative electrode, the added components of the electrolyte and the injection ratio of the electrolyte shown in Table 1 were used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com