Wall structure detection device for old community reconstruction planning

A technology of wall structure and detection device, which is applied in the direction of sampling device, material inspection product, mechanical thickness measurement, etc., can solve the problems of staff interference, impact of drill pipe, and low service life, so as to improve structural stability and avoid detection Error, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

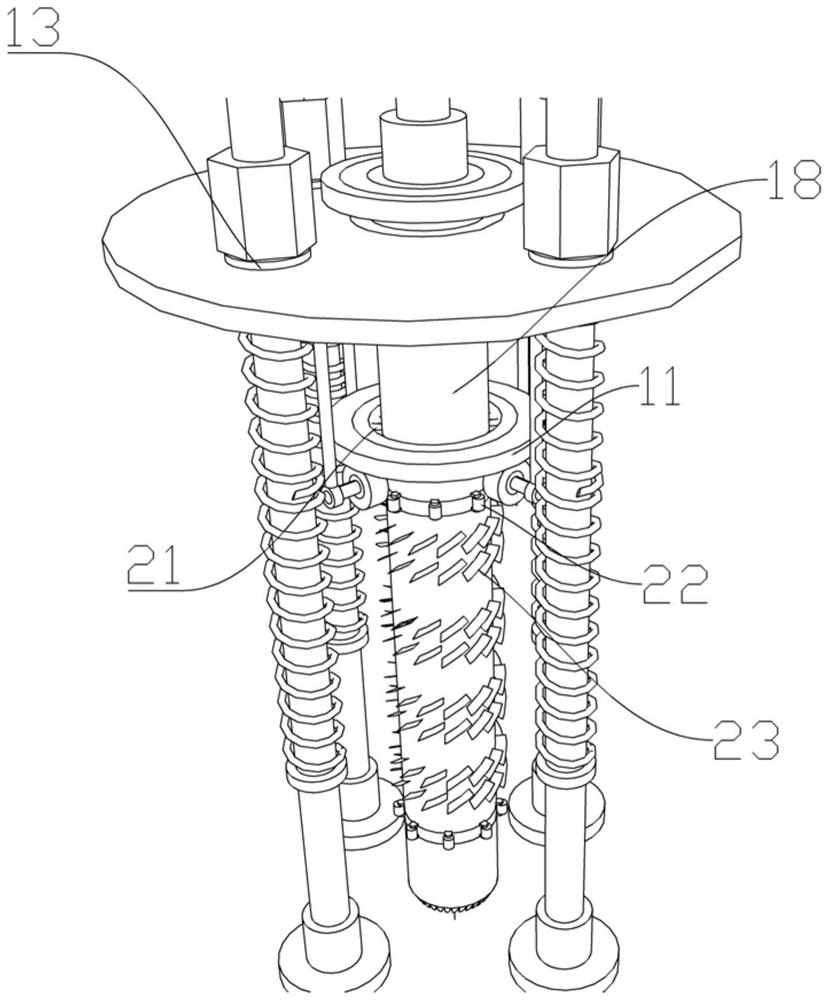

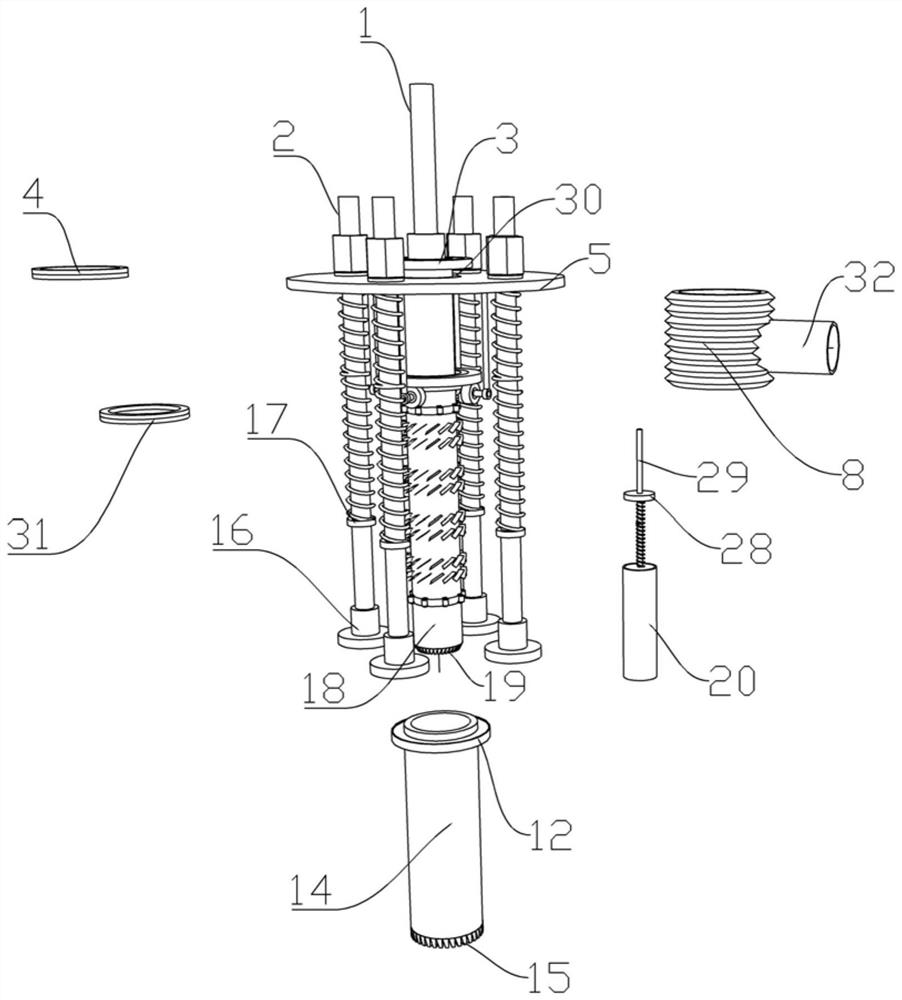

[0034] like Figure 1-6 As shown in the figure, a wall structure detection device for the renovation planning of an old residential area includes a fixed frame body, a first drill pipe 18, a second drill pipe 14, and a sampling pipe 20 components;

[0035] The middle part of the fixed frame body is rotatably connected with a first drill rod 18 through a first bearing 30 . The inside of the drill rod 18 is provided with a sampling tube 20 assembly that can extend in and out, and a second drill rod 14 is sleeved on the outside of the first drill rod 18 , and a space between the second drill rod 14 and the first drill rod 18 There is a ash layer, there are multiple groups of blast blades 23 in the ash layer, the first drill rod 18 is fixed with the upper toothed plate 11 through the first connecting rod 21, and the upper toothed plate 11 passes through the second bearing. 31 is rotatably connected to the lower toothed plate 12 at the upper end of the second drill pipe 14, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com