Adjustable wire and cable winding mechanism

A wire and cable and winding mechanism technology, applied in the field of adjustable wire and cable winding mechanisms, can solve problems such as troublesome use, inconvenient adaptation to different scenarios, and large limitations, and achieve convenient use, easy promotion, and small limitations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

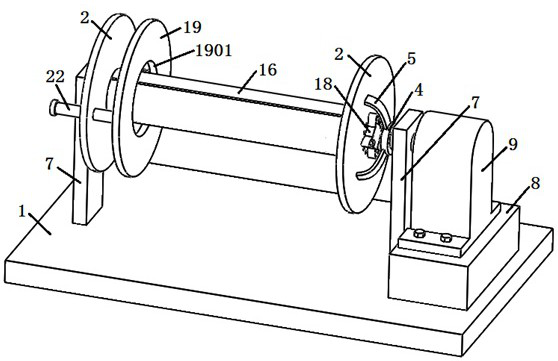

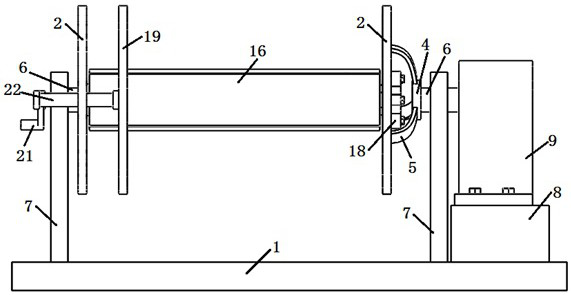

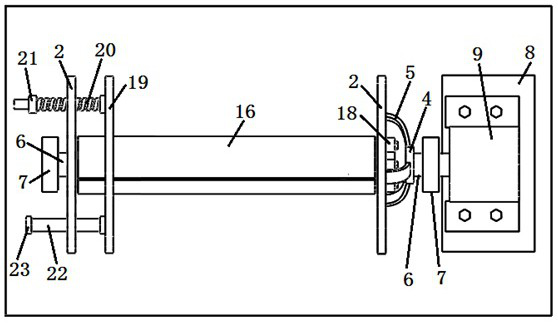

See Figure 1-6 , A regulatable wire and cable winding mechanism of this embodiment, including bottom board 1, which are symmetrically installed on the left and right sides of the upper surface of the bottom plate 1 with columns 7. Symptom setting of two wound disks 2, and the middle of the two winding disks 2 is installed and fixed by connecting the shell 13. In the middle of the connecting shell 13, there is a first turning shaft 3 in the central part of the interior. The two ends of the first turning shaft 3 can be installed on two winding disks 2, and the first turning shaft 3 passes through the right side of the right side. The adjustment mechanism on the winding disk 2 is fixed. The first turning shaft 3 is evenly installed with three arc -shaped cylindrical panels 16. These three arc -shaped cylindrical board 16 surround the formation of the wound, and the three arc -shaped cylindrical board 16 can be along the first turning shaft along the first turning shaft. 3 radial teles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com