Industrial belt glass fiber wire winder capable of performing stepless adjustment on tensioning force

A technology of stepless adjustment and glass fiber, which is applied in the field of industrial belt manufacturing equipment, can solve the problems of unstable glass fiber line routing, inability to realize stepless adjustment, and affect the processing quality of glass fiber line layers, etc., to achieve good practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

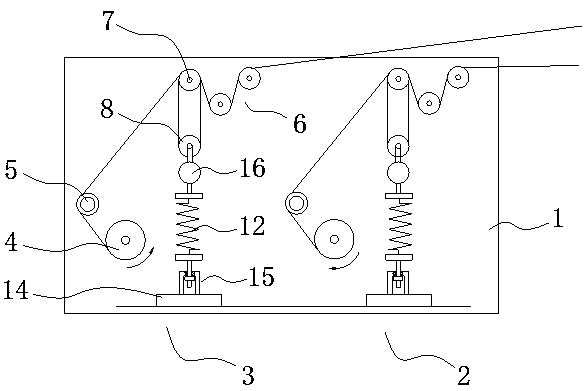

[0016] This embodiment proposes an industrial belt glass fiber wire winder with stepless tension adjustment to meet the winding requirements of the glass fiber wire.

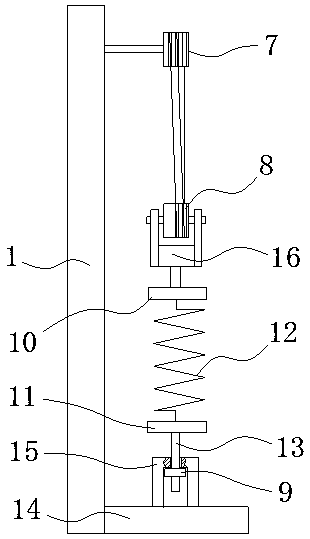

[0017] like figure 1 , 2 As shown, the industrial belt glass fiber wire winder for stepless adjustment of tension in this embodiment includes a vertical base 1, the side wall of which is provided with a set of wire feeding and winding devices 2 and a set of receiving The wire winding device 3, the wire feeding and winding device 2 and the wire taking and winding device 3 all include wire rollers 4, guide rollers 5, tension rollers, and crimping rollers 6 groups, and the wire feeding and winding devices 2 has the same structure as the take-up and winding device 3, except that the direction of the winding is opposite, which can ensure that both ends of the winding are subjected to a balanced tension, and can better improve the winding quality.

[0018] The tension roller group includes an upper fixed roller 7, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com