Explosion-proof vacuum packaging machine

A vacuum packaging machine, packaging machine technology, applied in the direction of packaging, packaging, transportation and packaging under vacuum/special atmosphere, can solve the problems of inconvenient disassembly and assembly, complicated connection relationship, inconvenient application and promotion, etc., and achieves complete display and sealing. Strong and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

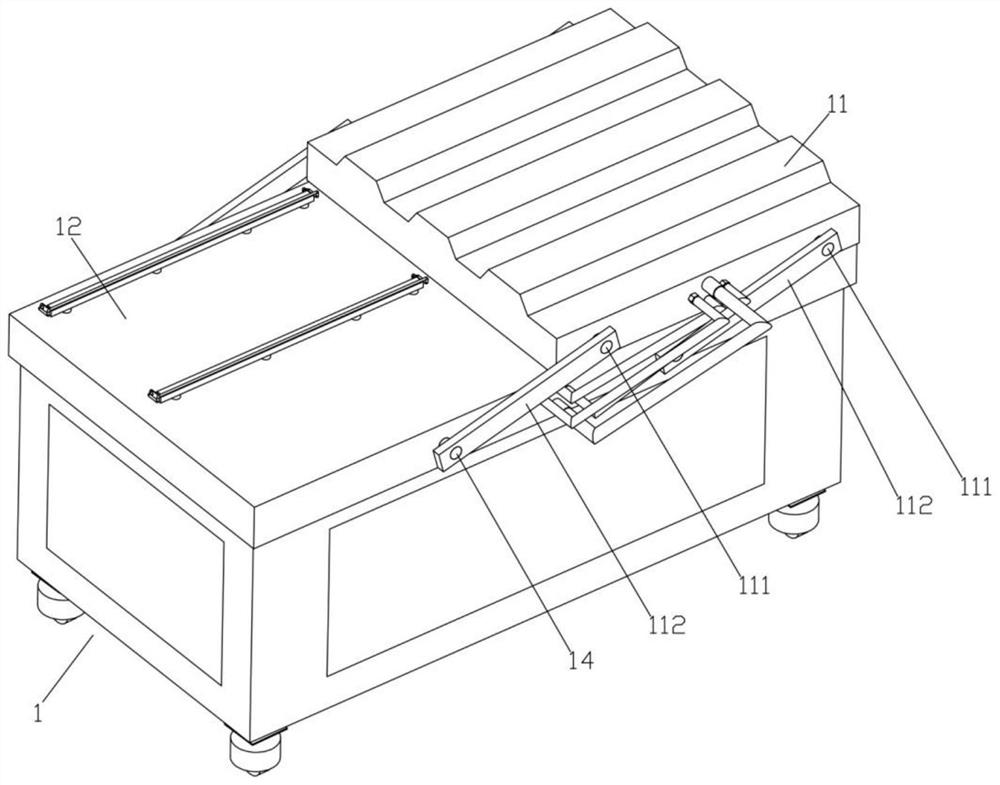

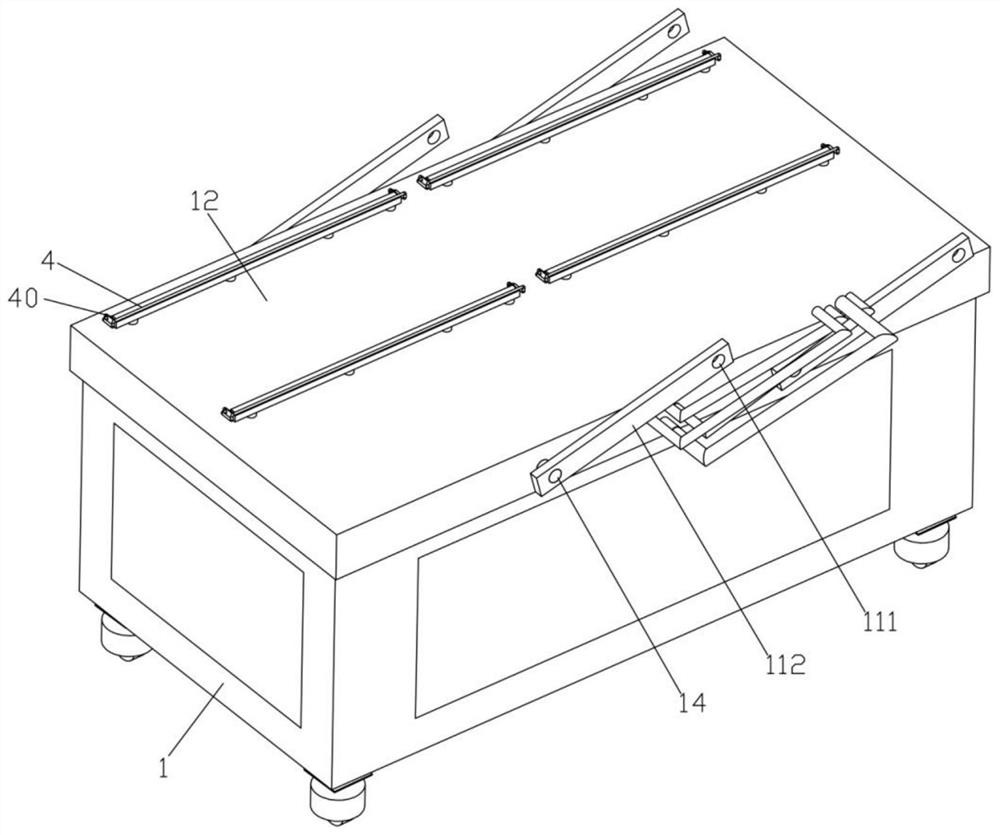

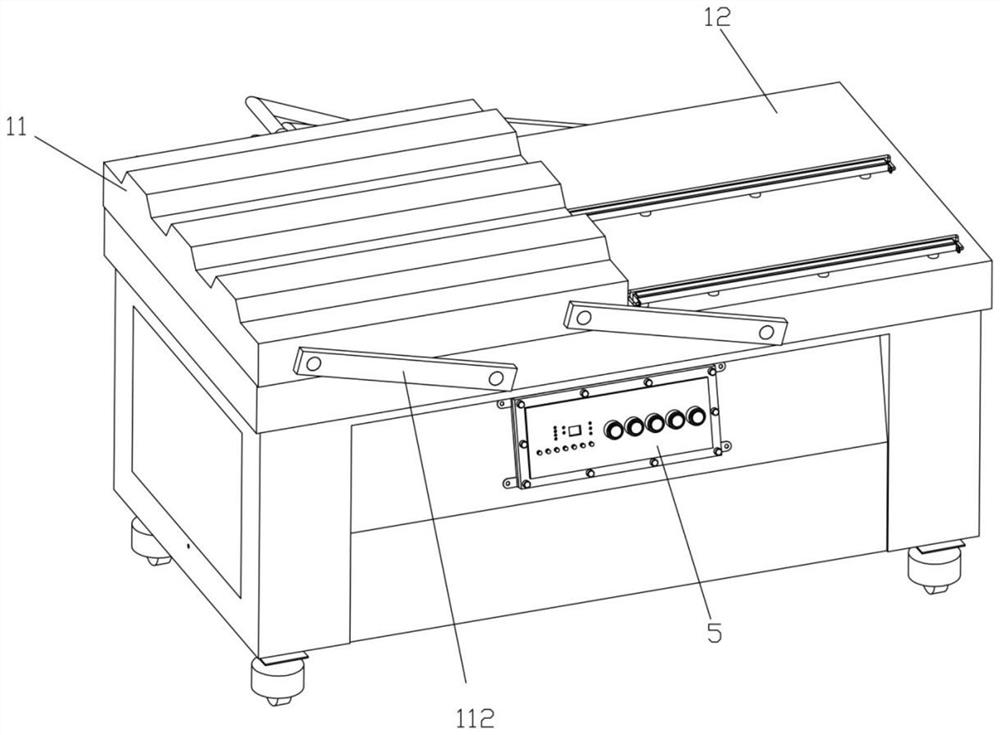

[0028] refer to Figure 1 to Figure 3 , an explosion-proof vacuum packaging machine, which includes a packaging machine main body 1 and a vacuum chamber cover 11 movably installed above the packaging machine main body 1, the top of the packaging machine main body 1 is provided with a vacuum chamber bottom plate 12, and the vacuum chamber bottom plate 12 is The vacuum chamber cover 11 is a shell structure with a cover at the bottom. The vacuum chamber cover 11 can be covered on one side of the vacuum chamber bottom plate 12 so that the vacuum chamber cover 11 is connected to the vacuum chamber bottom plate 12. There is a vacuum chamber 13 in between. The vacuum chamber 13 is provided with two sets of laterally arranged heat sealing mechanisms. The heat sealing mechanisms include an air bag 2 , a heating rod 3 and a silicone strip 4 . The expansion of the air bag 2 can reduce the distance between the heating rod 3 and the silicone strip 4 . The front center of the packaging mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com