Hose filling and tail sealing system and hose filling and tail sealing method

A filling device and hose technology, applied in the field of hose filling and sealing systems, can solve the problems of ill-considered aseptic process, unreasonable structural layout and high interchangeability requirements, achieve reasonable overall structural layout and improve production. Efficiency and production quality, the effect of low error rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

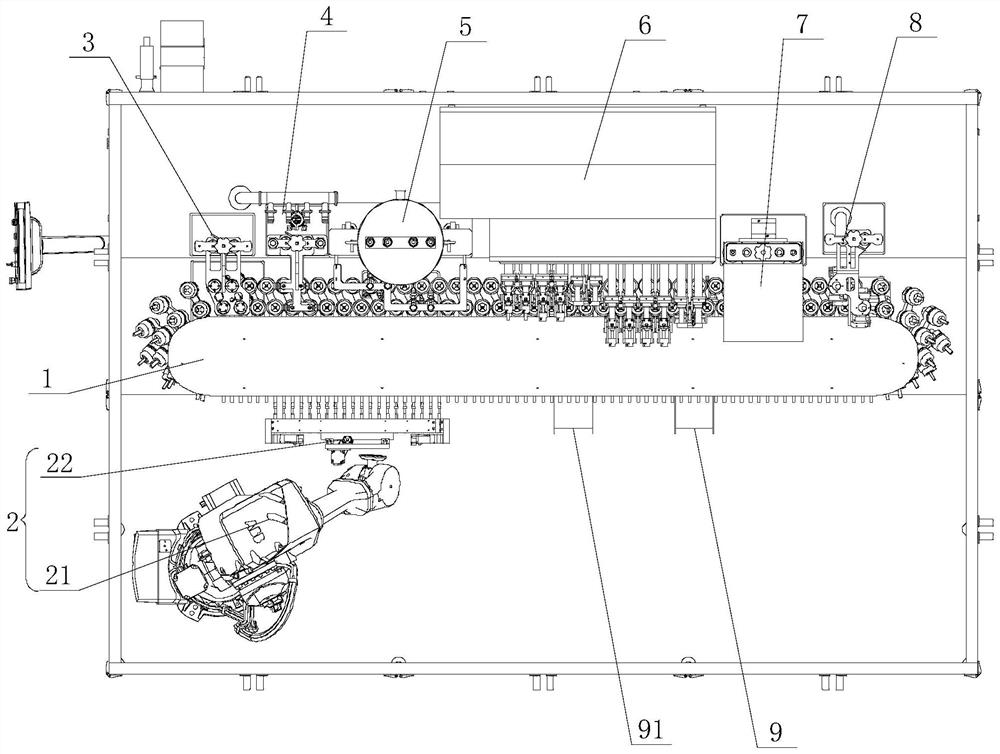

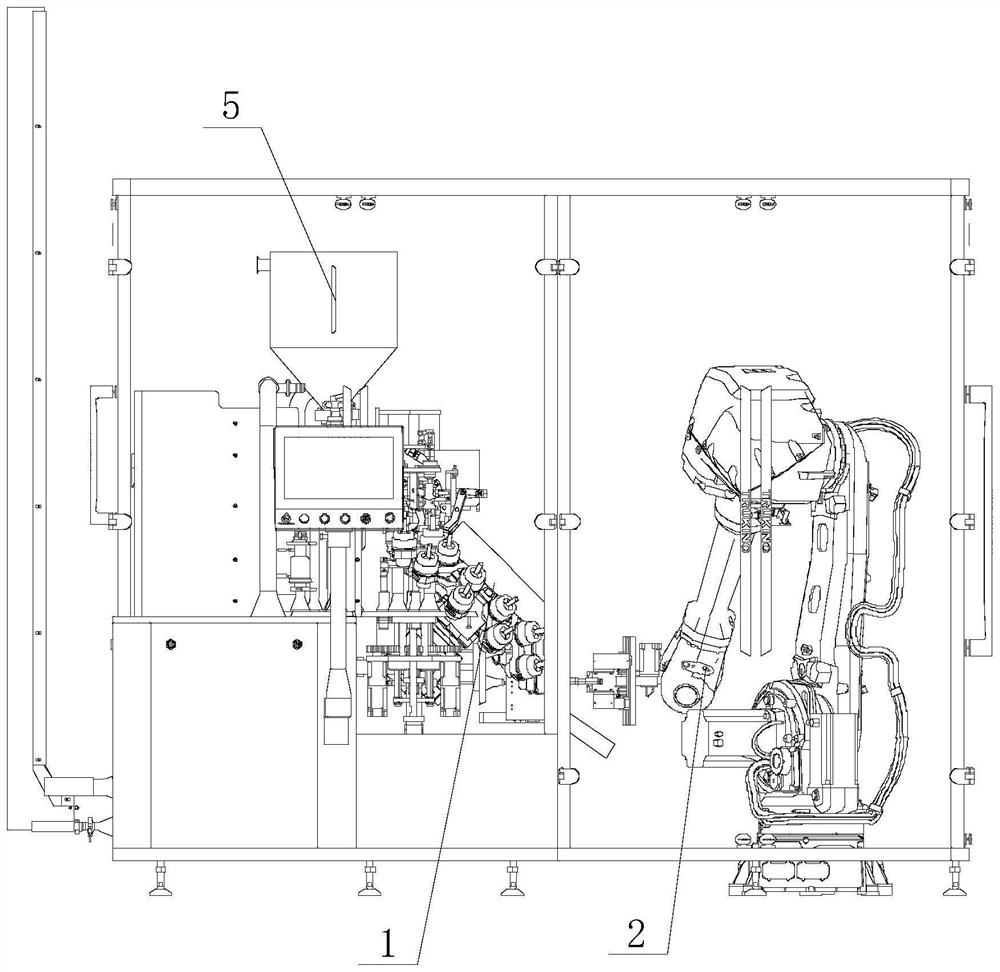

[0045] Figure 1 to Figure 11 As shown in the figure, the hose filling and sealing system of this embodiment includes an annular conveying device 1 for conveying hoses, and a variable-pitch feeding device 2, a benchmarking device 3, a blowing device 2 arranged in sequence along the conveying direction of the annular conveying device 1 Sweeping device 4, filling device 5, tail folding device 6, embossing device 7, visual inspection device 8, unloading device 9 and waste rejection device 91, one side of the annular conveying device 1 is the horizontal conveying side of the horizontal conveying hose, The other side is the upright conveying side of the upright conveying hose. The variable-pitch feeding device 2, the unloading device 9 and the rejecting device 91 are located on the horizontal conveying side of the annular conveying device 1. The loading device 5 , the tail folding device 6 , the imprinting device 7 and the visual inspection device 8 are located on the upright conve...

Embodiment 2

[0057] A method for filling and sealing a tube is carried out by using the above-mentioned system for filling and sealing a tube, comprising the following steps:

[0058] S1. Feeding: The variable-pitch feeding device 2 takes out the hose in the material box and transfers it to the feeding station on the horizontal conveying side of the annular conveying device 1, and then inserts the hose horizontally into the annular conveying device 1;

[0059] S2. Benchmarking: The annular conveying device 1 transfers the hose to the benchmarking station, and the benchmarking device 3 transfers the color mark of the hose to the same direction;

[0060] S3. Purge: The annular conveying device 1 transfers the hose to the purging station, and the inner wall of the hose is purged and cleaned by the purging device 4;

[0061] S4. Filling: The annular conveying device 1 transfers the hose to the filling station, and the filling device 5 fills the hose;

[0062] S5. Folding the tail: the annular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com