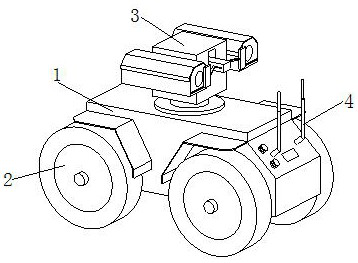

Full-automatic tunnel safety intelligent inspection equipment

An intelligent inspection and fully automatic technology, which is applied in the direction of motor vehicles, electric components, vehicle cleaning, etc., can solve problems such as stuck, blurred camera, and reduced scanning range of high-definition infrared cameras

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The wiping mechanism 33 includes a connecting rod 331, a guide rod 332, and a pushing mechanism 333. The inner end of the connecting rod 331 is fixed with the output end of the motor 32, and the outer end of the connecting rod 331 is welded with the inner end surface of the pushing mechanism 333. , the guide rod 332 is fixedly installed inside the waterproof mechanism 34, and the guide rod 332 passes through the inner end of the push mechanism 333 with clearance fit, the push mechanism 333 is installed at the outer front end of the waterproof mechanism 34, and the outer end of the push mechanism 333 is connected to the inner end of the push mechanism 333. The front end of the high-definition infrared camera 31 is in contact with each other, the guide rod 332 has an arc structure, and the arc center of the guide rod 332 and the output end of the motor 32 are located at the same point, so as to ensure that the output end of the motor 32 rotates to drive the push mechanism 3...

Embodiment 2

[0025] The heat exhaust mechanism 345 includes a heat collecting groove 45a, an expansion ball 45b, a heat sink 45c, and an opening and closing sheet 45d. The expansion ball 45b, the left end face of the expansion ball 45b is in conflict with the right end face of the heat sink 45c, the left end of the heat sink 45c is in conflict with the opening and closing sheet 45d, and the opening and closing sheet 45d is hingedly mounted on the left end of the heat collecting groove 45a Inside, the expansion ball 45b is made of metal zinc material, which has a good expansion coefficient. After absorbing heat, it expands, thereby pushing the heat sink 45c to move, automatically opening the opening and closing plate 45d, and expelling heat. Anyway, the opening and closing plate 45d is automatically closed to prevent external moisture from flowing into the interior of the casing 341 from the outer end of the heat collecting tank 45a.

[0026] The specific usage mode and function of this emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com