Railway vehicle wheel set tread 3D image detection method

A technology for rail vehicle and image detection, applied in the direction of rim measurement/measurement, etc., can solve the problems of low detection rate, low efficiency, irregular shape and size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below with reference to the accompanying drawings and embodiments.

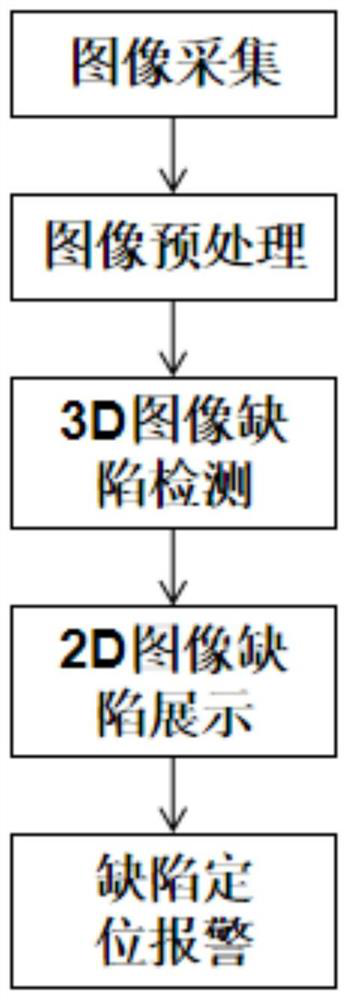

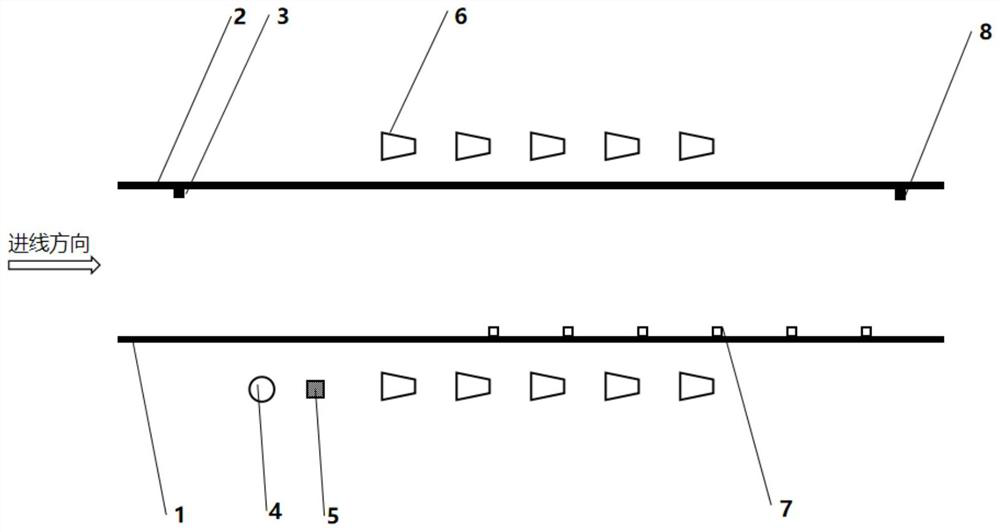

[0040] The workflow of the 3D image detection system for the wheelset tread of a rail vehicle in this embodiment is as follows: figure 1Shown: when there is no train entering the line, the detection system is in the state of dormancy and waiting to pick up the train; when the train enters the line, the wheels pass the line sensor 3, and the line sensor 3 triggers a valid incoming signal, then the detection system starts to enter the state of picking up the train, and the tread image is collected. Device 6 opens the protective cabin door, turns on the blower and dust removal device on the window glass, and at the same time, the window glass is heated to remove water mist. The detection system starts the speed measuring radar 4 to detect the passing vehicle speed, calculates the matching camera acquisition frame rate according to the vehicle speed, and send...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com