Vehicle sunshade curtain cover plate and vehicle sunshade curtain cover plate mounting structure

An installation structure and sunshade technology, which is applied to vehicle parts, transportation and packaging, windows, etc., can solve problems such as loose assembly of the sunshade cover and upper guard plate, affecting customer experience, and abnormal noise of the sunshade cover. To achieve the effect of easy assembly, structural enhancement and connection strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

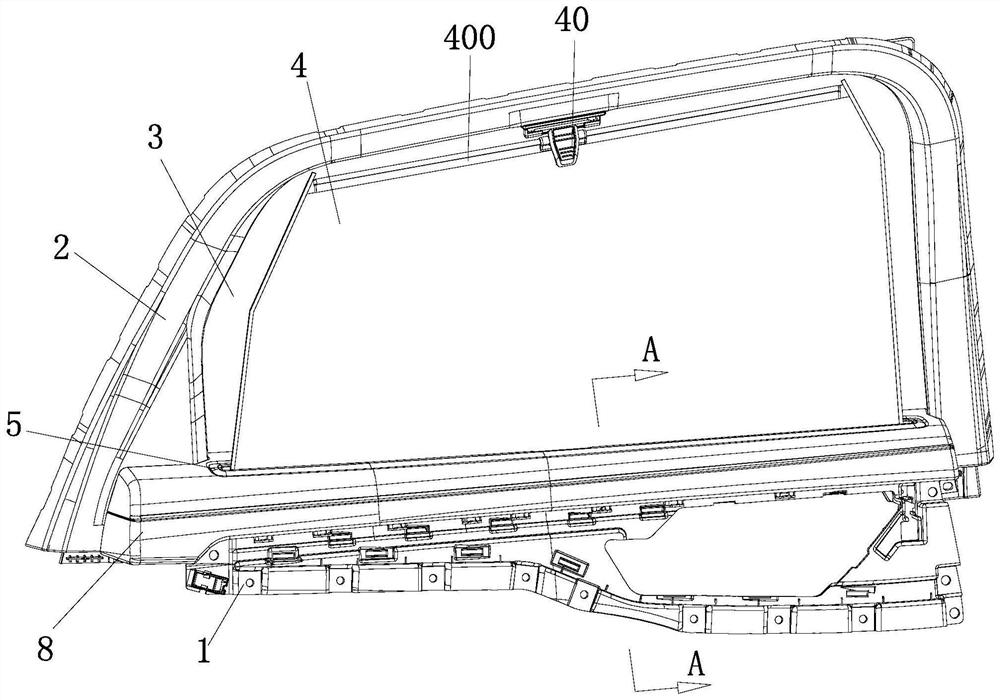

[0040] This embodiment relates to a vehicle sunshade cover. The vehicle sunshade cover is assembled on the upper guard plate of the vehicle compartment to modify the opening of the main body for accommodating the sunshade, which is beneficial to improve the vehicle sunshade cover, the upper The connection strength between the guard plate and the three parts of the main body can reduce the abnormal noise caused by the looseness of the sunshade cover.

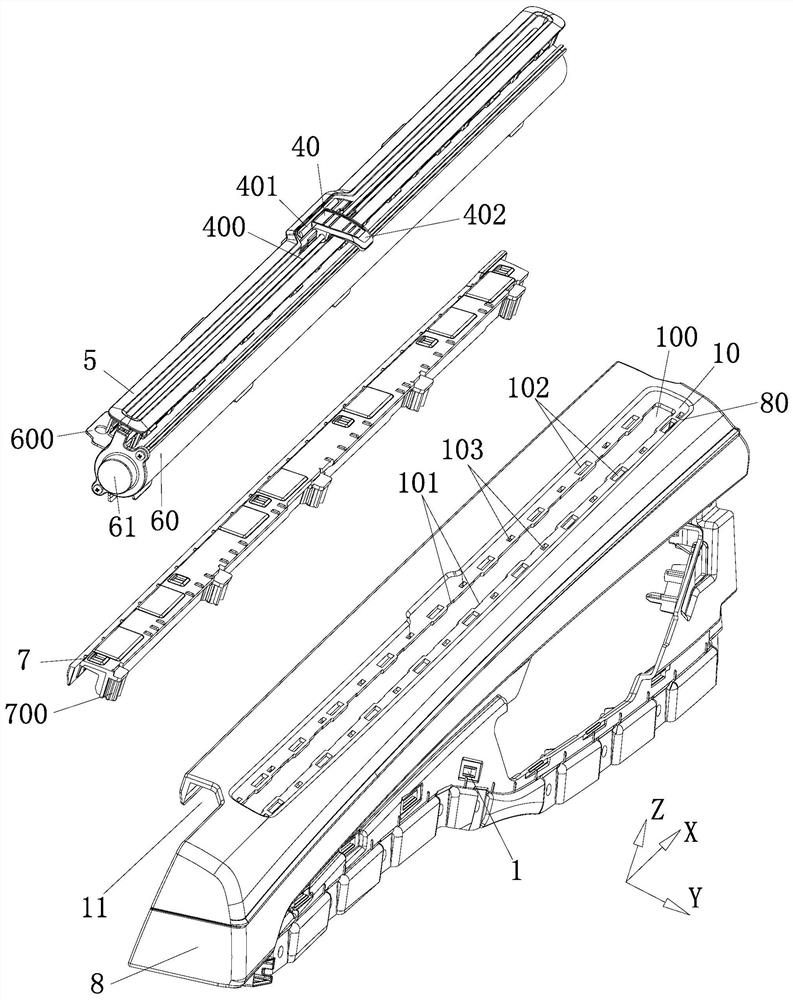

[0041] As a whole, the vehicle sunshade cover plate includes a plate body extending along the length of the vehicle, and four connection groups.

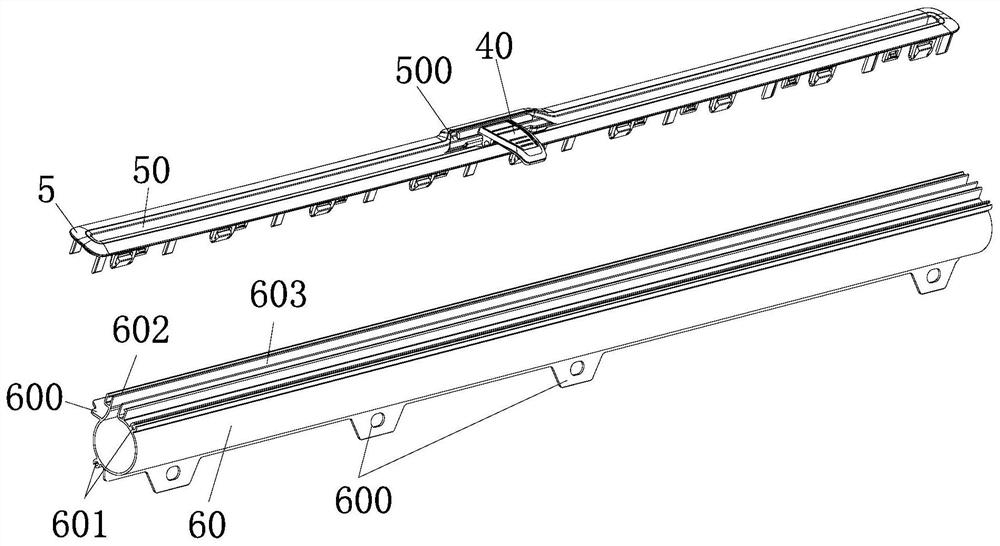

[0042] Among them, a belt outlet is formed transparently on the board main body, so that the sunshade can be led out from the belt outlet after passing through the opening. The two first connection groups are arranged side by side on both sides of the width direction of the opening, each first connection group is composed of a plurality of first connection pieces distributed at interva...

Embodiment 2

[0062] The present embodiment relates to a vehicle sunshade cover installation structure, the vehicle sunshade cover installation structure includes an upper guard plate 1 located in the cabin, and a main body 60 with an opening 603 for accommodating the sunshade 4, and at the same time , on the upper fender 1 and the main body part 60 , the vehicle sunshade cover plate of the first embodiment is connected to form a decorative covering for the main body part 60 at the opening part 603 . This design is beneficial to improve the connection strength between the three components of the vehicle sunshade cover, the upper guard and the main body, thereby reducing abnormal noises caused by the looseness of the sunshade cover.

[0063] A curtain rod 400 is provided on the upper edge of the sunshade 4, a handle 40 is fixed in the middle of the curtain rod 400, and a hanging shaft 401 is provided at one end of the handle 40 to cooperate with the hook on the upper part of the window to kee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com