Electric automatic industrial dust removal equipment

A technology for electrical automation and dust removal equipment, which is applied in the fields of smoke and dust removal, climate change adaptation, climate sustainability, etc. The effect of dust efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

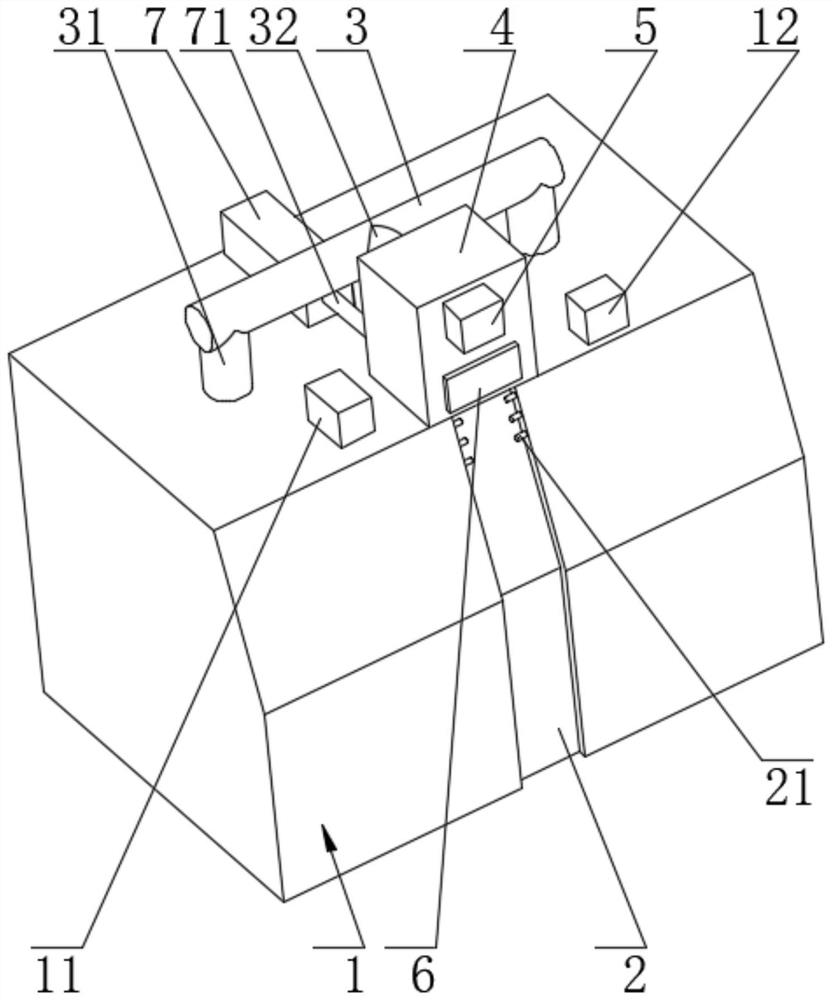

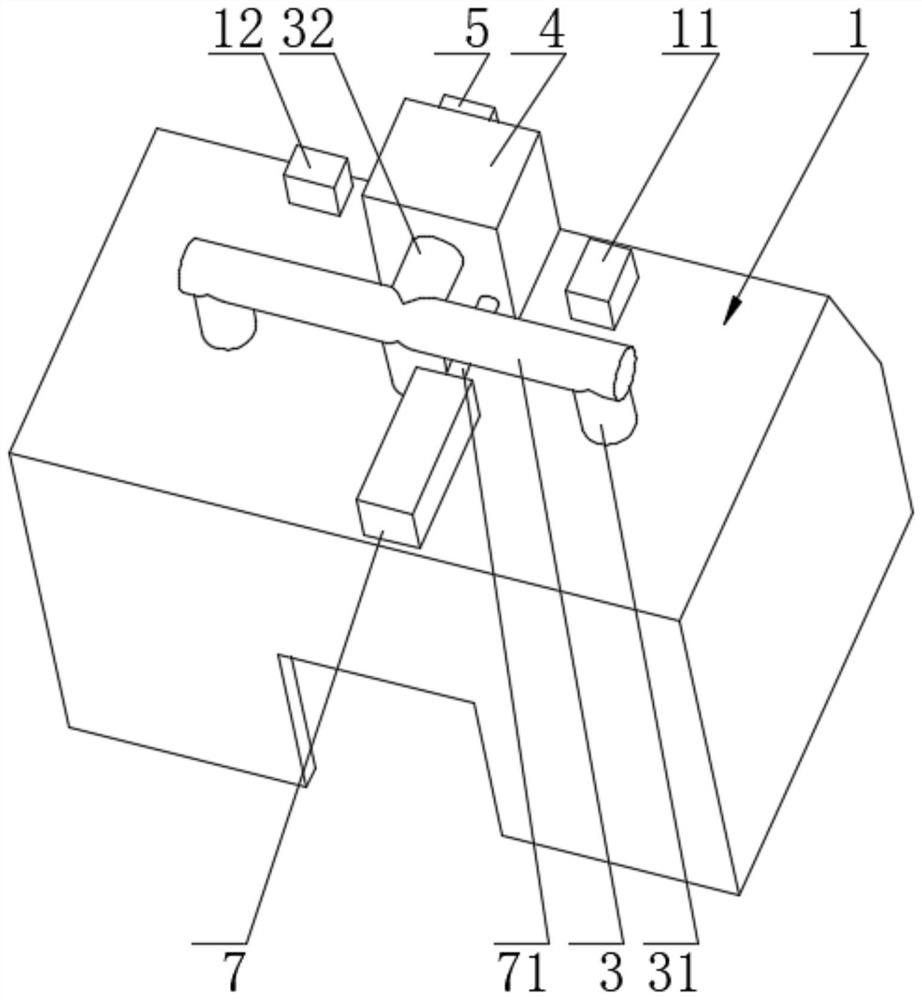

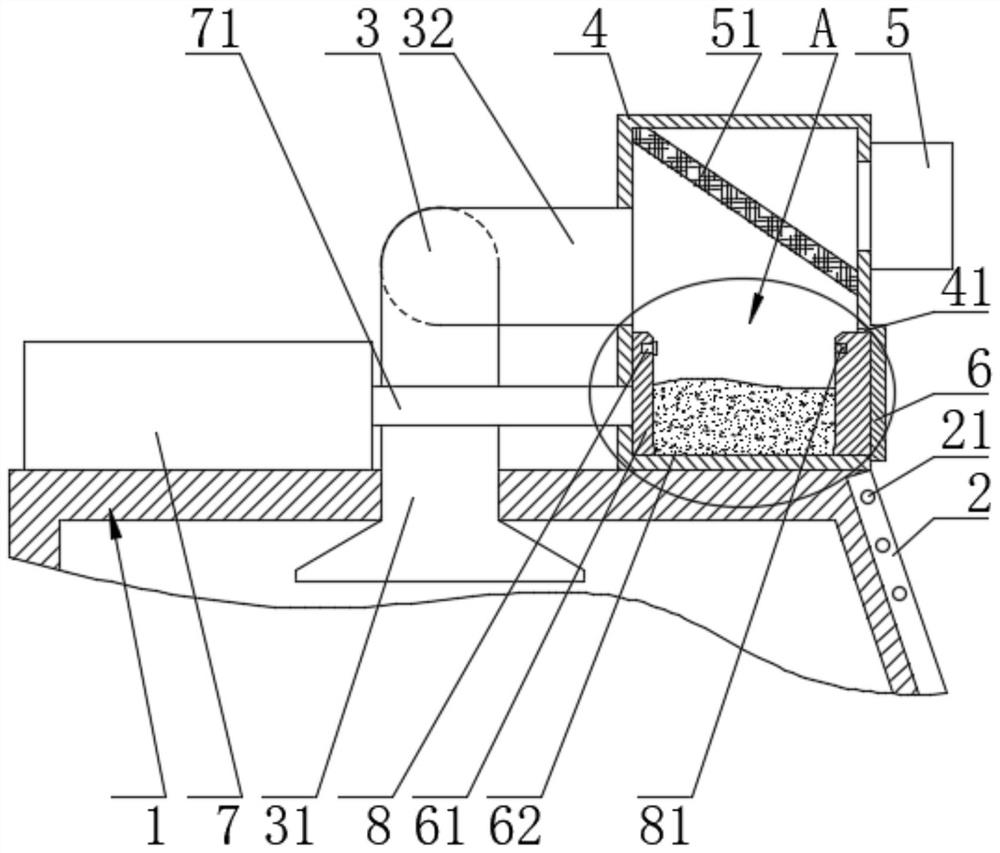

[0025] see figure 1 , figure 2 , image 3 , an electrical automation industrial dust removal equipment, including a workshop body 1, and a controller 11, a water pump 12, a slag discharge tank 2, a dust storage box 4, a dust extraction pipe 31, a cylinder 7, and a slag discharge tank arranged on the workshop body 1. The inner wall surface of 2 is installed with a water spray head 21, the water spray head 21 is connected with the water pump 12 through a preset water pipe, the water pump 12 is connected with the external water tank through a water suction pipe, and the top of the dust suction pipe 31 is provided with a connecting gas pipe 3, which is connected to the gas pipe 3. A dust extraction pipe 31 is connected to the top, and the dust extraction pipe 31 is communicated with the dust storage box 4. The dust storage box 4 is provided with a sliding port 41 and a vacuum cleaner 5. A dust filter screen 51 is installed in the dust storage box 4 through screws. 61 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com