Deodorant preparation method, deodorant and deodorization filter screen

A technology of deodorant and filter screen, which is applied in the field of deodorant preparation, deodorant and deodorization filter, and can solve the problems of poor long-term deodorization ability, easy decomposition and deterioration of capture agent, poor removal ability, etc. , to achieve better effect, long-lasting effect, and not easy to decompose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

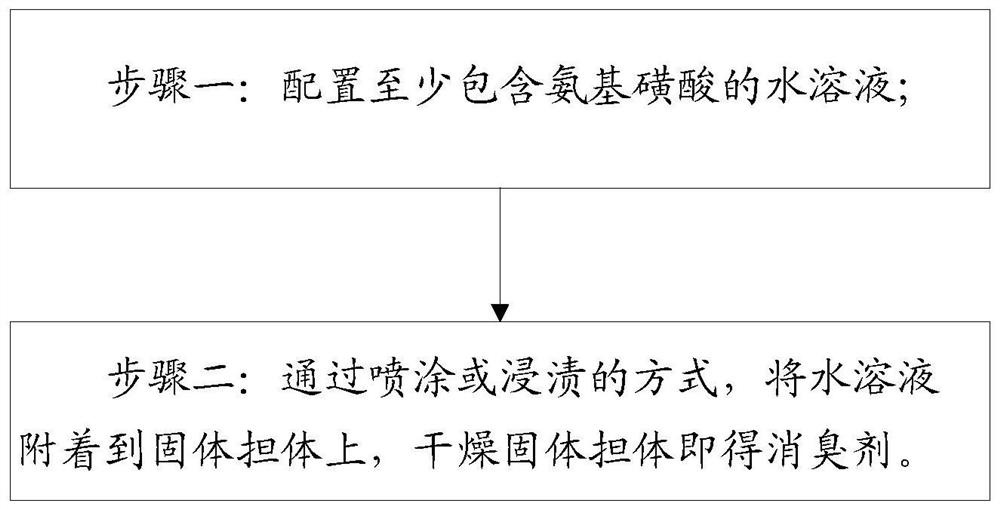

[0043] An embodiment of the present invention discloses a method for preparing a deodorant, such as figure 1 As shown, the preparation method includes:

[0044] Step 1: prepare an aqueous solution containing at least sulfamic acid; mix at least sulfamic acid and water in a certain proportion to obtain an aqueous solution, and the mixing can be achieved by stirring or ultrasonication.

[0045] Step 2: The aqueous solution is attached to the solid carrier by spraying or dipping, and the solid carrier is dried to obtain a deodorant. Specifically, the aqueous solution can be sprayed onto the fixed support by a spraying machine, or the solid support can be immersed in the aqueous solution for a period of time, so that the aqueous solution can be attached to the solid support. The solid support to which the aqueous solution is attached can be placed in an oven or drying oven for drying.

[0046] The deodorant prepared by the method in this embodiment can effectively remove aldehyd...

Embodiment 1

[0071] The coal-based columnar activated carbon with a carbon tetrachloride adsorption value of 65% and a diameter of 2 mm was selected as a solid support, and the solid support was immersed in an aqueous solution with a concentration of sulfamic acid of 3%, the immersion time was not less than one minute, and then passed through The activated carbon is separated from the aqueous solution by centrifugal separation, and the deodorant can be prepared by hot air drying at a drying temperature of 60° C. and a moisture content of less than or equal to 12%.

Embodiment 2

[0073] The coal-based columnar activated carbon with a carbon tetrachloride adsorption value of 65% and a diameter of 2 mm was selected as the solid support, and the solid support was immersed in an aqueous solution with a sulfamic acid concentration of 3% and a 2-imidazolidinone concentration of 2%. The immersion time is not less than one minute, and then the activated carbon is separated from the aqueous solution by centrifugal separation, and then dried with hot air. The drying temperature is 60 ° C, and the moisture content is less than or equal to 12%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com