Fermentation equipment and method for dairy products

A technology for fermentation equipment and dairy products, which is applied in milk preparations, dairy products, applications, etc., can solve problems such as poor operability, residual liquid additives, and difficulty in tank cleaning, and achieves convenient cleaning, improved production efficiency, and easy cleaning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

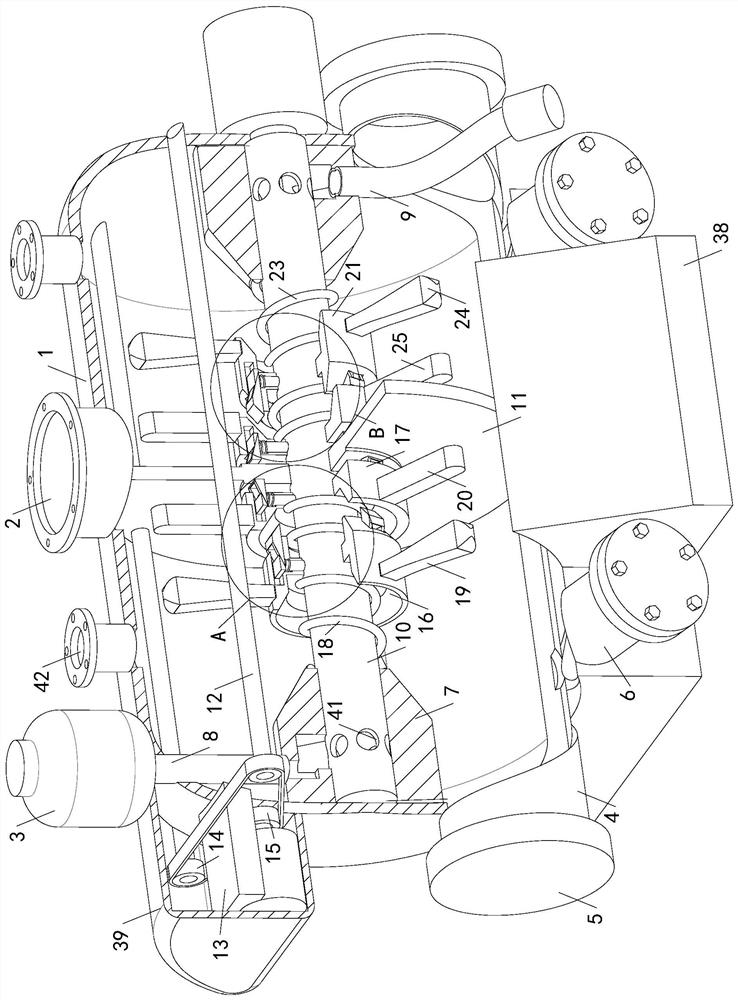

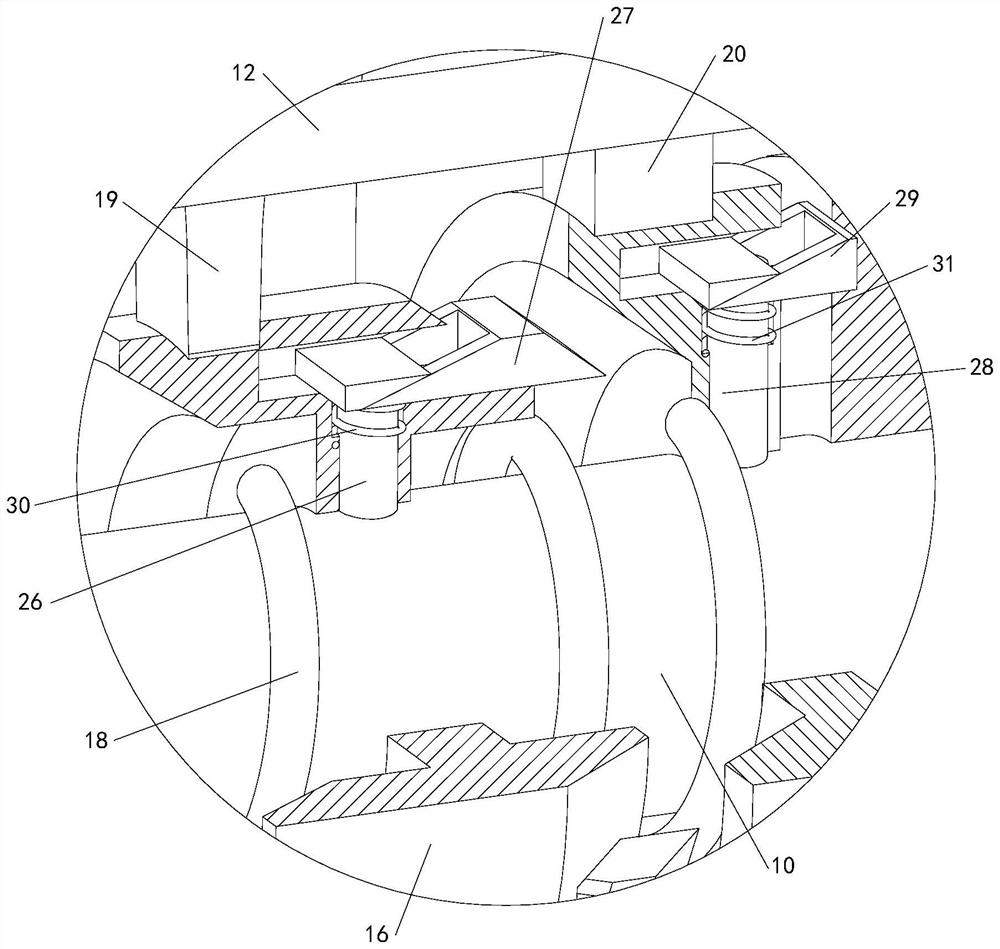

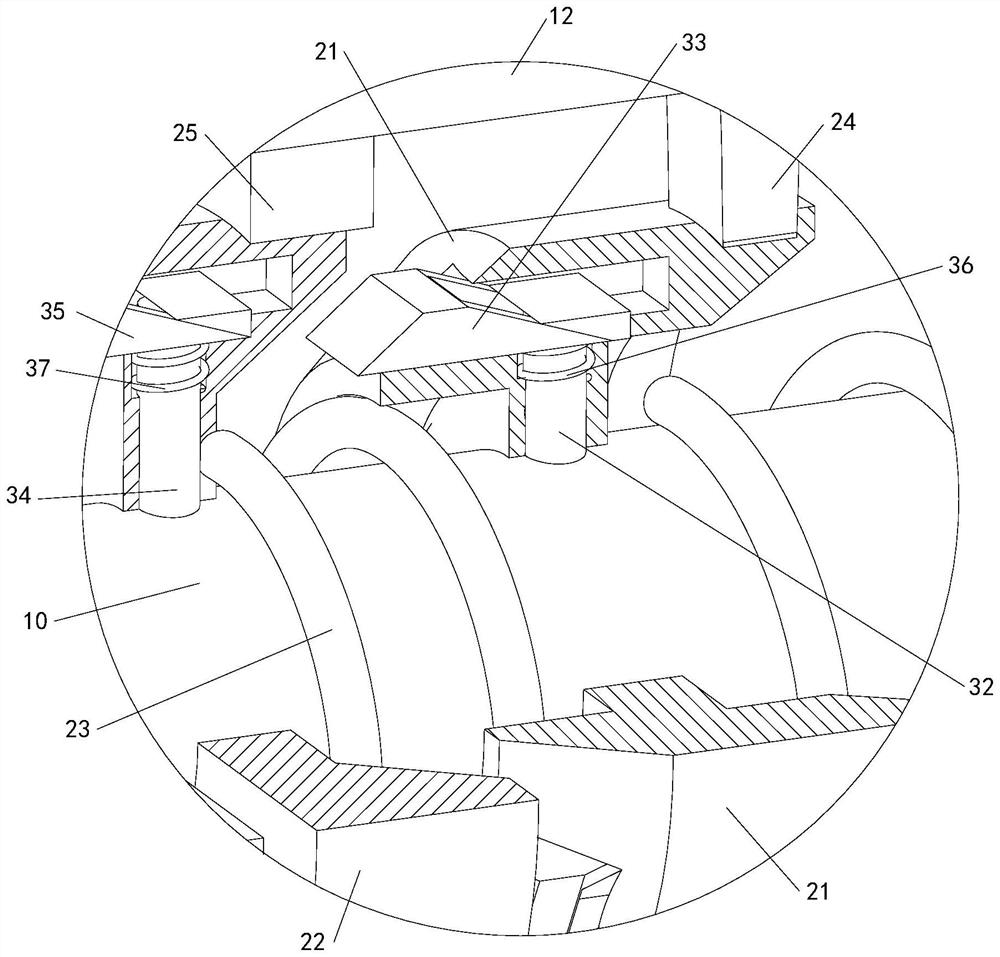

[0033] see Figure 1-5 , a fermentation equipment for dairy products, including a horizontal tank 1, the upper part of the tank 1 is provided with a main feeding port 2, and also includes an auxiliary material tank 3, the top of the tank 1 is provided with two exhaust pipes 42, two The exhaust pipes 42 are arranged symmetrically on the left and right, and the left and right ends of the tank body 1 are provided with manhole pipes 4 . The cleaning of the two relatively independent spaces on the left and right of The bottom end of the body 1 is provided with a support table 38, the top of the support table 38 is a circular groove structure matching the tank body 1, and the front end of the support table 38 is provided with a gap matching the discharge pipe 6, so as to realize the support of the tank body 1. At the same time, the passage of the discharge pipe 6 is convenient. Two base sleeves 7 are fixedly connected in the tank body 1. The bottom end of the auxiliary material tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com