Armature core polishing device for electric tool

A technology of armature iron core and polishing device, which is applied in the direction of grinding/polishing safety device, device for fixing grinding wheel, manufacturing tools, etc. It can solve the problems of polishing tool wear and damage, not easy to repair, difficult to control polishing accuracy, etc. To achieve the effect of easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

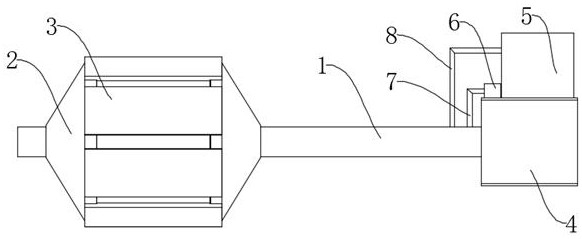

[0055] The present invention provides such Figure 1-10 The shown armature core polishing device for electric tools includes a transmission rod 1, a fixed assembly 2 is arranged on the transmission rod 1, and a polishing assembly 3 for polishing the armature core is arranged on the fixed assembly 2, The end of the transmission rod 1 is provided with a drive assembly for driving the transmission rod 1 to rotate, and the drive assembly is provided with a medium adding assembly for adding cooling medium to the fixed assembly 2;

[0056] The fixing assembly 2 includes a housing 11 fixed on the outer ring of the transmission rod 1, one end of the housing 11 is fixed on the transmission rod 1 by a screw, the housing 11 is a conical shell structure, and the housing 11 is provided with a Two groups, two groups of casings 11 are symmetrically distributed with respect to the polishing assembly 3;

[0057] The polishing assembly 3 includes a polishing and grinding plate 12 and an outer ...

Embodiment 2

[0091] The present invention provides such as Figure 1-10The shown armature core polishing device for electric tools includes a transmission rod 1, a fixed assembly 2 is arranged on the transmission rod 1, and a polishing assembly 3 for polishing the armature core is arranged on the fixed assembly 2, The end of the transmission rod 1 is provided with a drive assembly for driving the transmission rod 1 to rotate, and the drive assembly is provided with a medium adding assembly for adding cooling medium to the fixed assembly 2;

[0092] The fixing assembly 2 includes a housing 11 fixed on the outer ring of the transmission rod 1, one end of the housing 11 is fixed on the transmission rod 1 by a screw, the housing 11 is a conical shell structure, and the housing 11 is provided with a Two groups, two groups of casings 11 are symmetrically distributed with respect to the polishing assembly 3;

[0093] The polishing assembly 3 includes a polishing and grinding plate 12 and an oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com