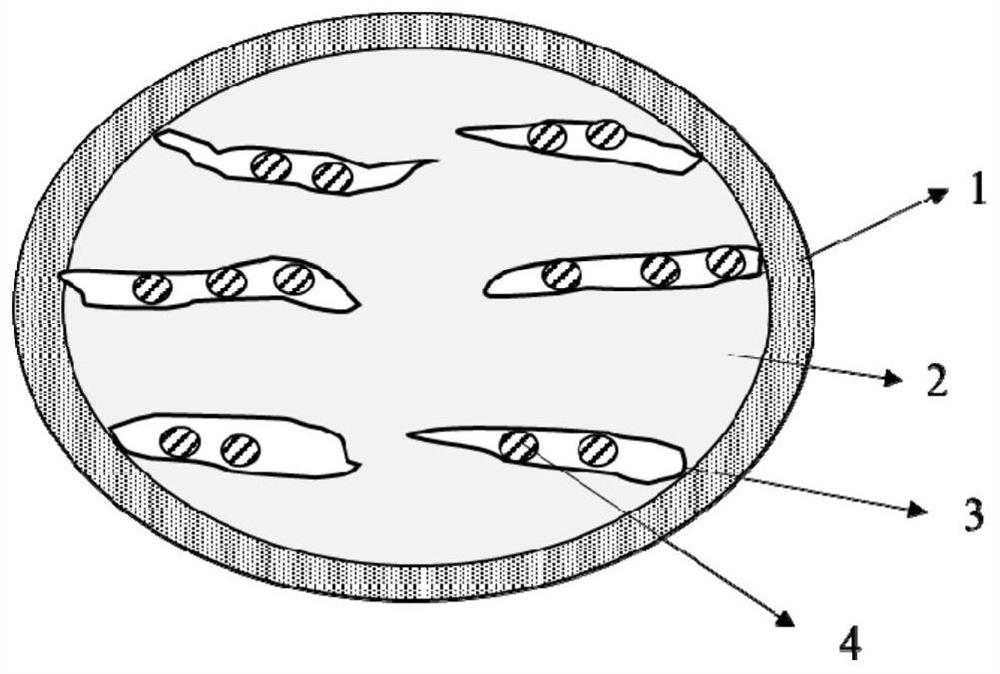

Negative electrode material and preparation method thereof, negative electrode plate, electrochemical device and electronic device

A technology of negative electrode material and negative electrode plate, which is applied in the field of electrochemistry and can solve the problems of reduced rate, need for improvement, difficult preparation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

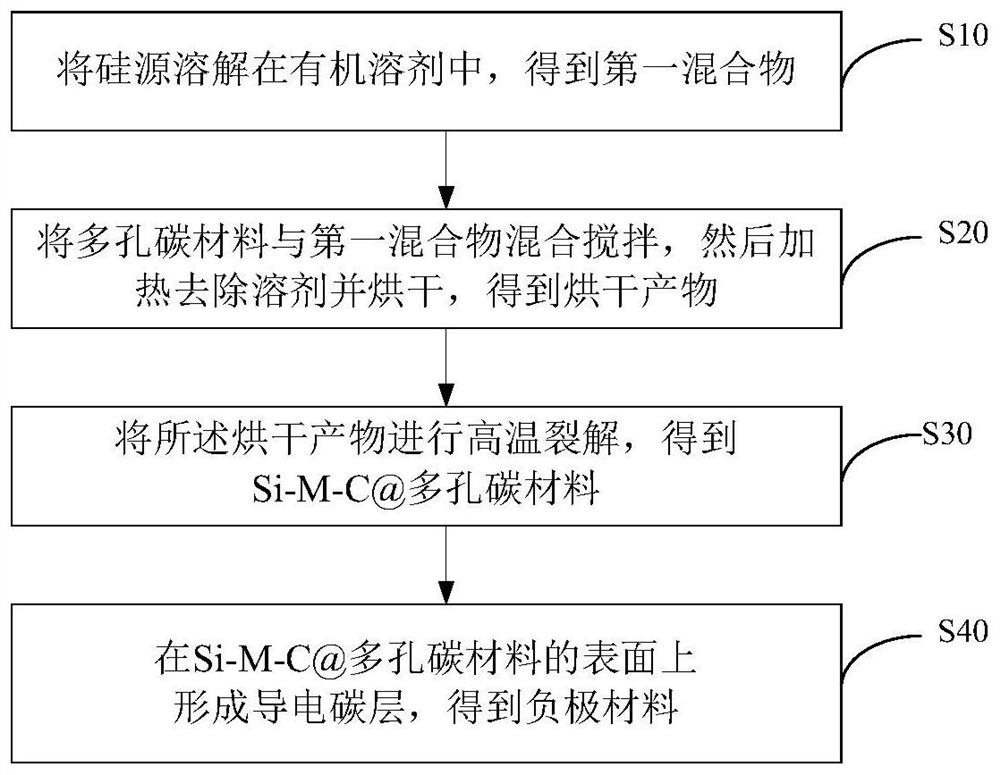

Method used

Image

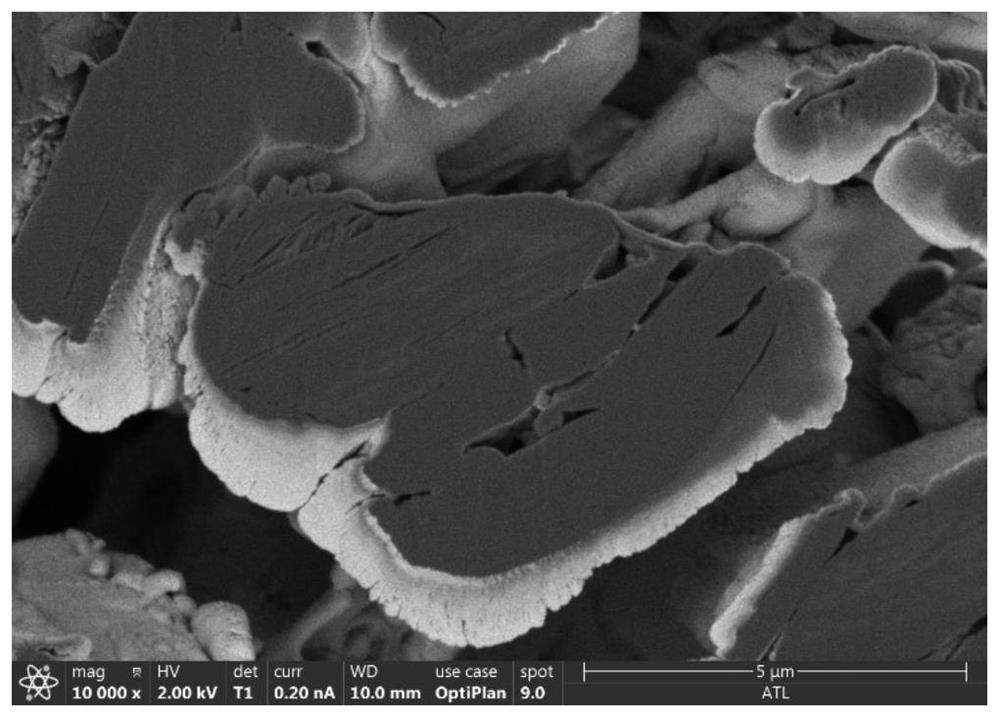

Examples

preparation example Construction

[0050] The above-mentioned negative electrode material can be quickly and effectively prepared by this method, the steps are simple, the operation is easy, and the cost is low. At the same time, the obtained negative electrode material has good electrical conductivity and ion transport performance, and the use of the negative electrode material can be improved. Cycling and kinetic performance of electrochemical devices. In this method, an organic silicon source is further selected and compounded with porous graphite to obtain a negative electrode material with long cycle and low expansion, which is suitable for lithium ion batteries and realizes low-cost industrialization.

[0051] In yet another aspect of the present invention, the present invention provides a negative pole piece. According to an embodiment of the present invention, the negative electrode sheet includes the aforementioned negative electrode material, wherein the peel strength between the negative electrode ma...

Embodiment 1

[0072] Embodiment 1: 100g polydimethylsiloxane (molecular formula is (C 2 H 6 OSi) n ), the mass of which is all converted into SiOC (ie Si-M-C) is (28+16+12) / (12×2+1×6+16+28)×100=75.7g, then the content of SiOC is 75.7 / (75.7+175+5)=29.6%;

Embodiment 2-4

[0073] Example 2-4: The calculation method is the same as that in Example 1, except that Si-M-C in Example 2 is SiNC, and Si-M-C in Example 3 is Si 4 BO 3 C 4 , Si-M-C in Example 4 is SiOC+SiNC with a ratio of 1:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com