Lift enhancement assembly for aircraft with fixed wings

A technology of lifting components and aircraft, applied in the field of aircraft, can solve problems such as cumbersome and idle rotors, and achieve the effects of reducing resistance, increasing range, and increasing endurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

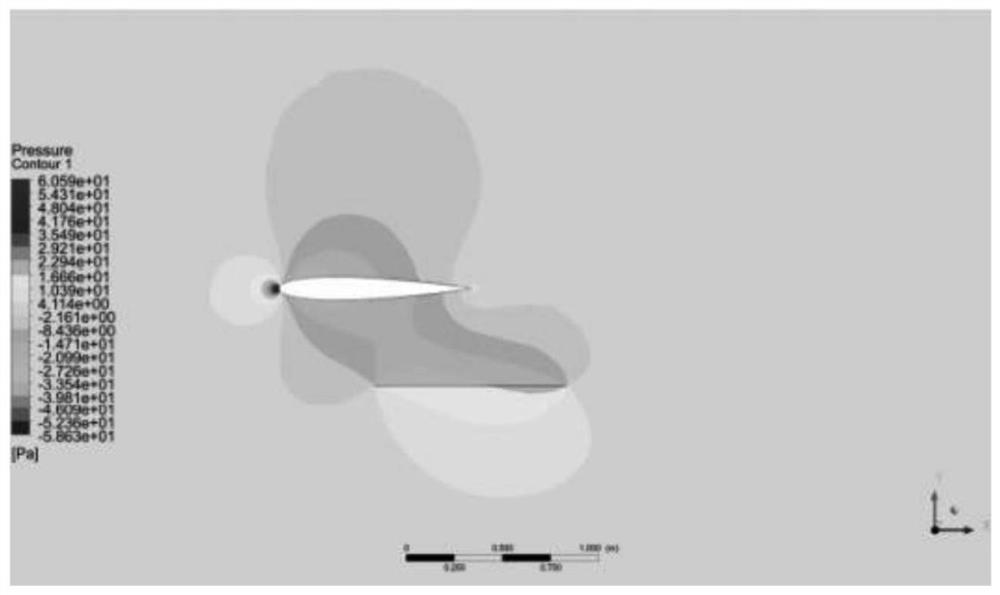

[0037] In aircraft with fixed wings, lift is generated by the wings during forward flight. As air flows over the wing during forward flight, the shape and direction of the wing creates a pressure field, with the low pressure at the top of the wing called the suction side and the high pressure below the wing called the pressure side. Lift is created by the pressure field.

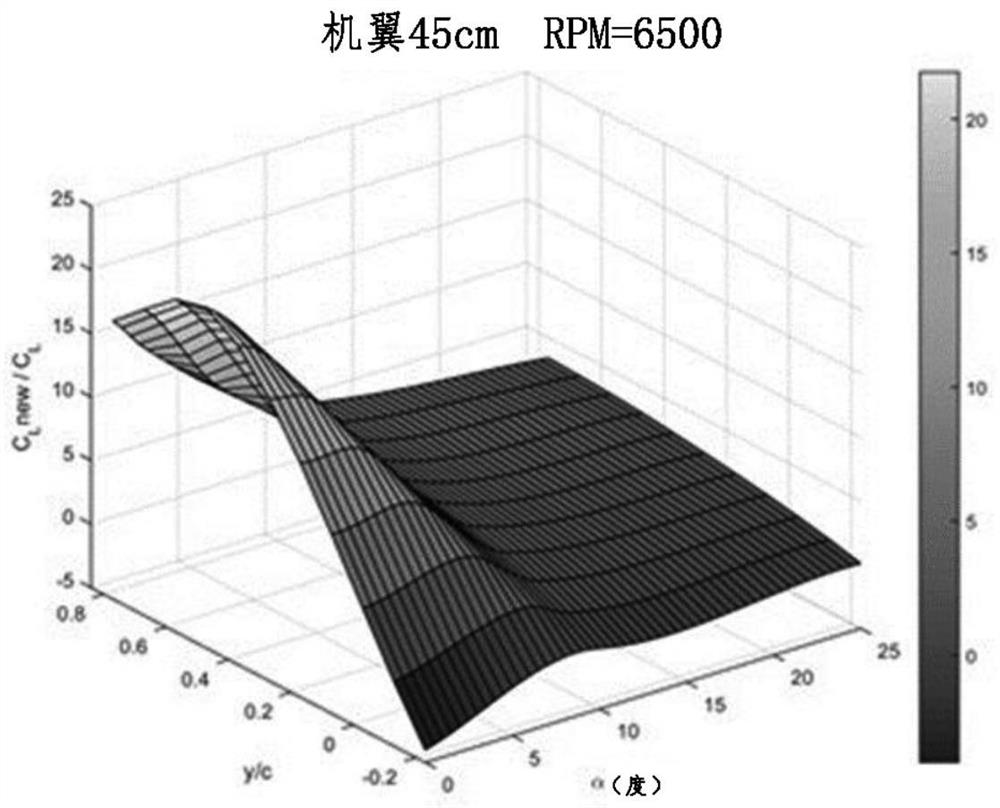

[0038] Additionally, the vertical rotors are set up for use during takeoff, landing and hovering. But during forward flight, the vertical rotor becomes a burden. The present invention develops a lift assembly that utilizes the lift provided by operating the vertical rotor during forward flight. The presence of the rotor and its operation changes the flow field and thus the pressure field around the wing.

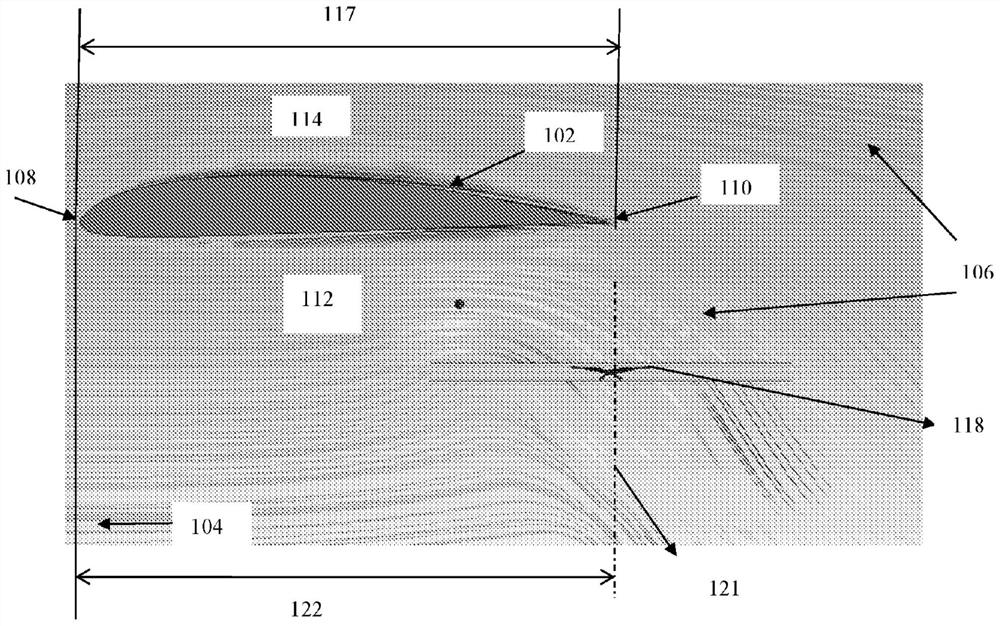

[0039] figure 1 The airflow in front of the fixed wing and the operable vertical rotor in an embodiment of the invention is shown. A section of the fixed wing 102 is shown. Arrow 104 indicates the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com