Explosion-proof flame-retardant electrical control cabinet capable of efficiently bundling

An electrical control cabinet, flame-retardant technology, applied to electrical components, substation/switch layout details, substation/power distribution device shell, etc., can solve the problems of complex clustering, long clustering process, confusion, etc., and achieve high clustering efficiency, The effect of reducing the winding rate and increasing the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] like Figure 2-Figure 4As shown, the clustering mechanism includes a clustering ring 8, the two ends of the inner wall of the clustering ring 8 are fixedly provided with a limit block 10, the middle position of one end of the outer wall of the clustering ring 8 is fixedly provided with a first positioning rod 11, and one end of the outer wall of the first positioning rod 11 A connecting rod 12 is interspersed, and the other end of the first positioning rod 11 outer wall is interspersed with a first spring 13, and one end of the first positioning rod 11 is fixedly provided with a first spacer 14, and the two ends on one side of the connecting rod 12 are arranged Fixing strips 15 are fixedly arranged, and one end of the outer wall of the two fixing strips 15 is interspersed with the two ends on one side of the outer wall of the cluster ring 8 respectively, and the other end of the outer wall of the two fixing strips 15 is connected with the two ends of the other side of th...

Embodiment 2

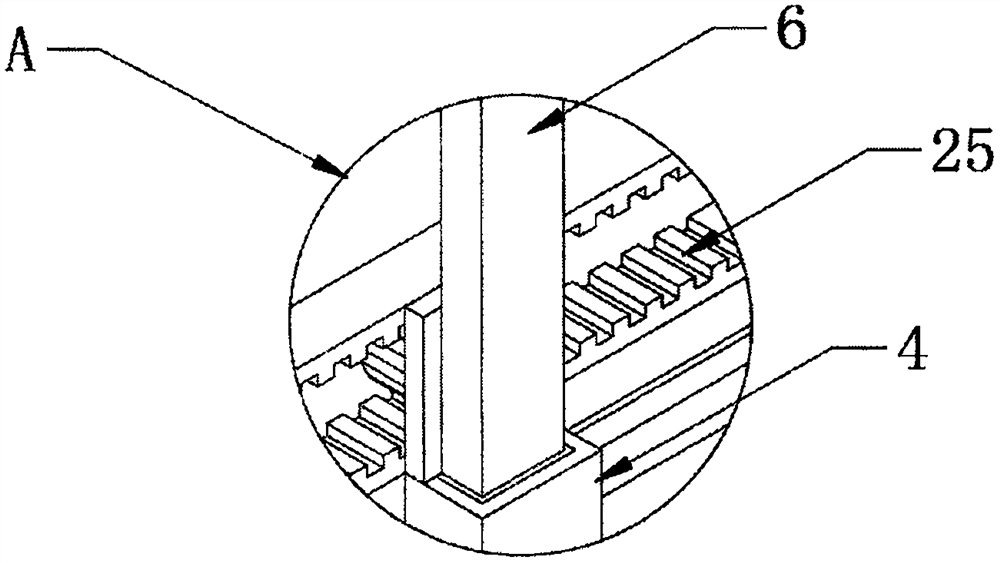

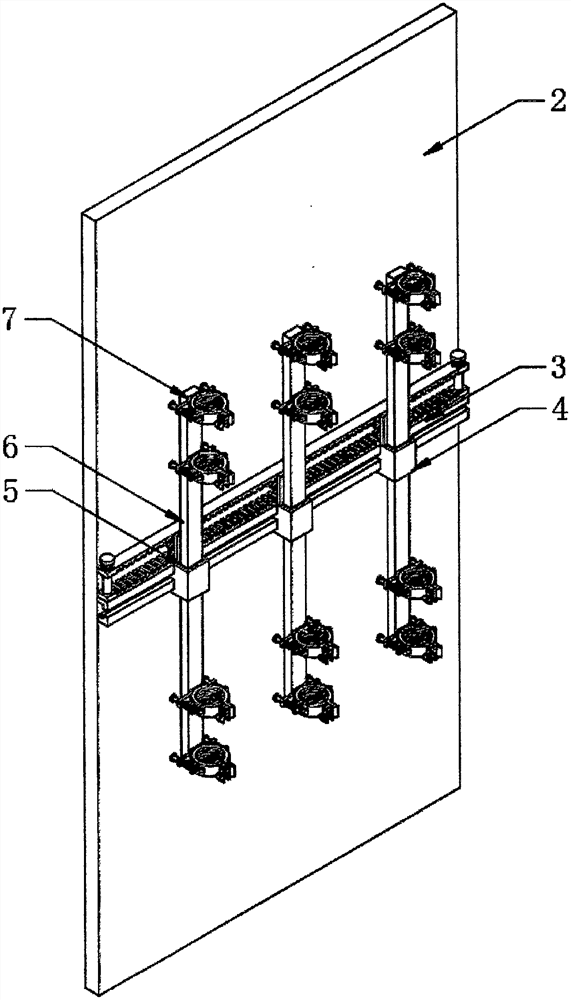

[0035] like Figure 4-Figure 6 As shown, one end of the top of the three positioning blocks 4 is fixedly provided with a baffle plate 23, and the middle positions on one side of the three baffle plates 23 are all rotated to be provided with a gear 24, and the top of the slide rail 3 is fixedly provided with a first rack 25, One end of the tooth surfaces of the three gears 24 is meshed with the tooth surface of the first rack 25, and the two ends of the top of the first rack 25 are fixedly equipped with a third positioning rod 26, and one end of the outer walls of the two third positioning rods 26 are connected to each other. The second tooth bar 27 is interspersed, and one end of the outer wall of the two third positioning rods 26 is inserted and connected with the two ends of the top of the second tooth bar 27 respectively, and the other end of the outer wall of the two third positioning rods 26 is interspersed with the second tooth bar. Three springs 28, the tops of the two ...

Embodiment 3

[0037] like Figure 8 As shown, one end on one side of the electrical control cabinet body 1 is hingedly provided with a protective door 31, and the four sides on one side of the electrical control cabinet body 1 are fixedly provided with sealing strips 30, and the four sides on one side of the protective door 31 are all fixed. A sealing groove 32 is provided, so that the electrical control cabinet body 1 can obtain the effect of explosion-proof and flame retardant, and reduce the immersion of water vapor and water flow, etc., so as to protect the electrical control cabinet body 1 .

[0038] The working principle of this embodiment: when it is necessary to use an explosion-proof and flame-retardant electrical control cabinet that can be clustered efficiently, such as Figure 1-Figure 3 and Figure 4-Figure 7 As shown, when it is necessary to bundle multiple electric wires inside the electrical control cabinet body 1, the worker pulls up the second rack 27, so that the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com