Lossless drying device and drying method based on coal rock mass ultrasonic monitoring

A drying device and ultrasonic monitoring technology, applied in the direction of drying gas arrangement, static material dryer, drying solid material, etc., can solve the problem of mechanical damage, drying damage and complete drying affecting the accuracy and science of mechanical tests and physical and mechanical parameter tests sex and other issues to achieve the effect of improving accuracy and scientificity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

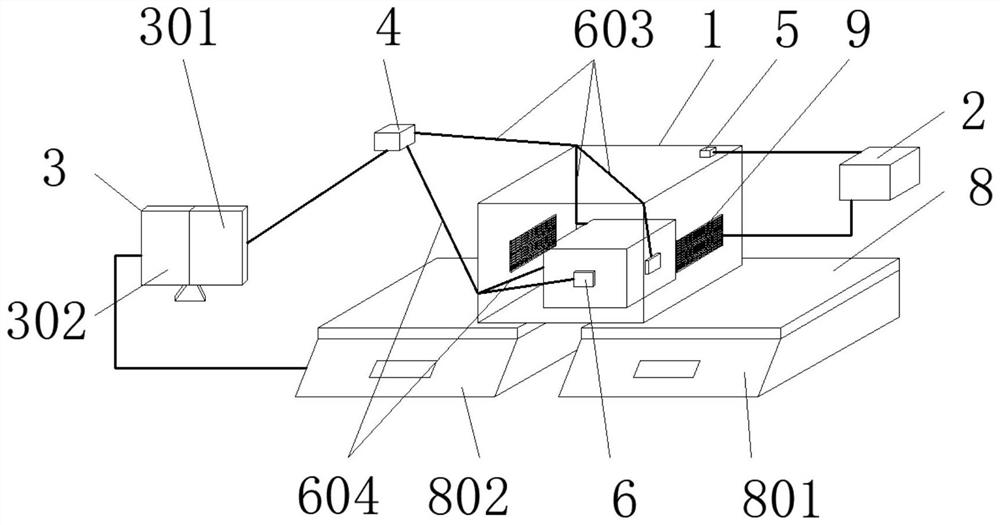

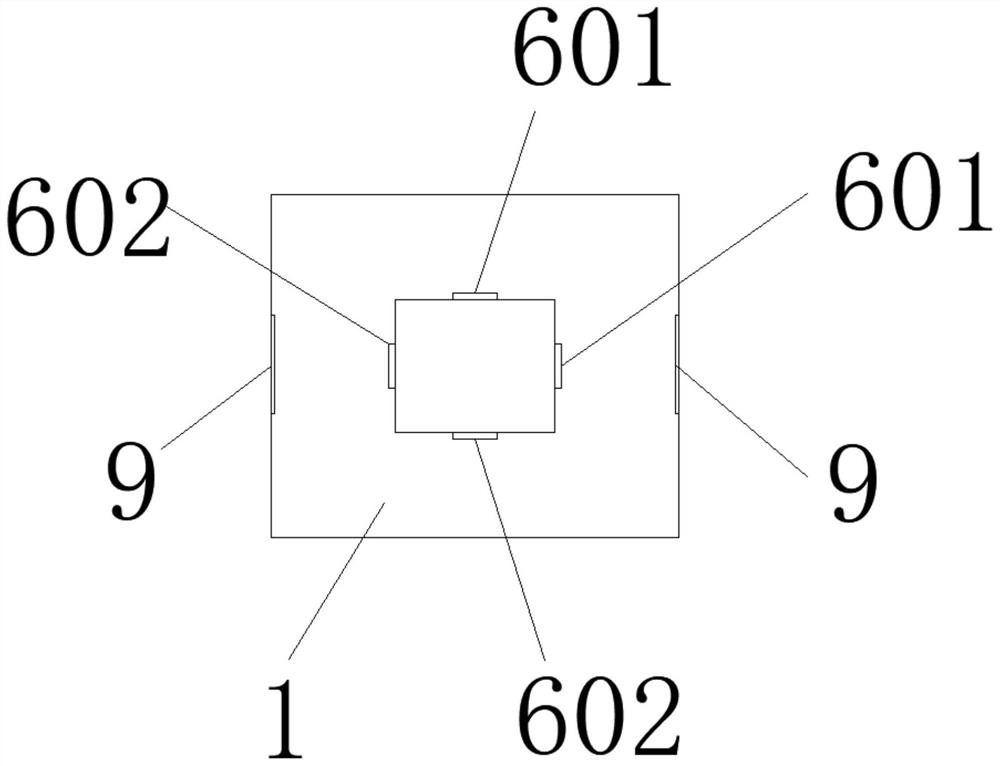

[0032] refer to Figure 1-2 , the present invention provides a technical solution, a non-destructive drying device based on ultrasonic monitoring of coal and rock mass, comprising a drying device temperature-isolated sealing box 1, a drying device temperature control module 2, a monitoring display screen 3, an ultrasonic monitoring and control module 4, an air The extraction valve 5 and the heating module 9, the heating module 9 and the air extraction valve 5 are respectively connected with the temperature control module 2 of the drying device;

[0033] The air extraction valve 5 is installed on the temperature insulation sealing box 1 of the drying device, the heating module 9 is installed on the inner wall of the temperature insulation sealing box 1 of the drying device, and the coal rock sample 7 to be dried is placed in the temperature insulation sealing box 1 of the drying device. An ultrasonic testing device 6 is arranged on the side of the rock sample 7 for real-time mo...

Embodiment 2

[0043] refer to Figure 1-2 , on the basis of embodiment 1, the present invention provides a kind of technical scheme, the drying method based on non-destructive drying device, comprises the following steps:

[0044] S1: Fix the coal and rock sample 7 to be dried in the temperature-insulation sealing box 1 of the drying device, arrange an ultrasonic testing device 6 on the side of the coal-rock sample 7, and set a quality monitoring balance 8 under the temperature-insulating sealing box 1 of the drying device;

[0045] S2: Turn on the ultrasonic monitoring and control module 5 to monitor the initial ultrasonic signal of the coal and rock samples 7. According to the detection results of the longitudinal wave velocity of different coal and rock masses, adjust the air extraction valve 5 through the drying device master control module 1 to select hot air drying mode or vacuum thermal drying mode; select the drying temperature, and control the heating module 9 through the drying de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com