Method and device for optimizing and improving rock stratum fracturing permeation enhancement based on fracturing fluid viscosity

A fracturing fluid and viscosity technology, applied in the field of oil and gas wells, can solve the problems of incompletely developed fracturing fluid viscosity to form complex fractures, etc., and achieve the effects of simple structure, accelerated formation time, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

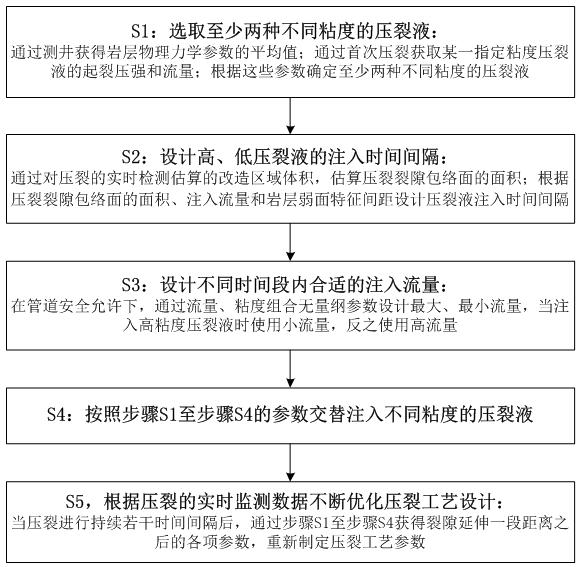

[0077] like figure 1 As shown, the method for improving rock formation fracturing and permeability enhancement based on fracturing fluid viscosity optimization according to the present invention includes the following steps:

[0078] S1: Select at least two fracturing fluids with different viscosities. Specifically, it includes: obtaining the average value of the physical and mechanical parameters of the rock formation through logging; obtaining the fracturing pressure and flow rate of a fracturing fluid of a specified viscosity through the first fracturing; and determining at least two fracturing fluids with different viscosities according to these parameters.

[0079] S2: The injection time interval of the designed high and low pressure fracturing fluid. Specifically, it includes: estimating the area of the fracturing fracture envelope through the estimated volume of the reformed area through real-time detection of fracturing; designing the fracturing fluid injection tim...

Embodiment 2

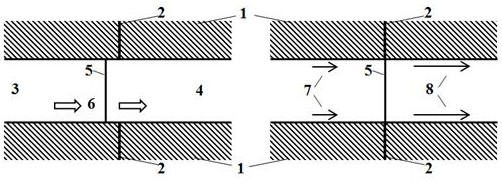

[0085] figure 2 It is a schematic diagram of the principle of shear stress fracturing on the fracture surface. The high viscosity fracturing fluid 4 and the low viscosity fracturing fluid 3 flow in the fracture surface one after the other, generating shear stress on the wall surface of the rock mass 1 .

[0086] Since the flow rates of the two fracturing fluids are almost the same, the shear stress 8 of the high-viscosity fluid is greater than the shear stress 7 of the low-viscosity fluid, there is a shear stress difference at the interface 5 of the two fracturing fluids, and the shear stress difference is further formed inside the rock mass 1 along the flow Tensile stress in direction 6; continue to inject fracturing fluid, fracturing fluid interface 5 flows forward, when fracturing fluid interface 5 moves to weak surface 2 of the rock mass, if the tensile stress is enough to overcome the confining pressure and the weak surface binding force, A new crack face will be formed ...

Embodiment 3

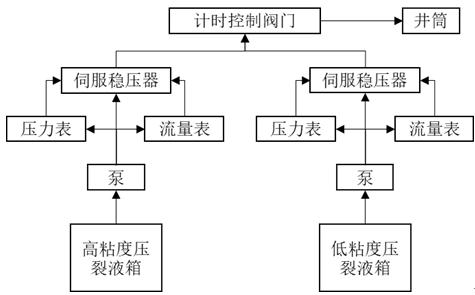

[0118] like Figure 5 The principle structure block diagram of the device of the present invention is shown, including a high-viscosity fracturing fluid tank, a low-viscosity fracturing fluid tank, and a fracturing fluid supply system. The low-viscosity fracturing fluid is built in the fluid tank, and the high-viscosity fracturing fluid and the low-viscosity fracturing fluid are respectively injected into the wellbore intermittently with different viscosities of fracturing fluids through the fracturing fluid supply system.

[0119] The fracturing fluid supply system consists of pumps, pressure gauges, flow meters, servo regulators, and timing control valves located between the high viscosity fracturing fluid tanks and the low viscosity fracturing fluid tanks.

[0120] In addition, the operating steps of the fracturing fluid supply system are as follows:

[0121] a. Select the fracturing fluid through step S1 and put it into the high-viscosity fracturing fluid tank and the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com