After-drilling reamer capable of preventing blade pin shaft from falling

A technology of eye reamer and blade, which is applied in the direction of drill bit, earthwork drilling, drilling equipment, etc. It can solve the problems of pin sticking, easy falling off of pin shaft, etc., and achieve the effect of preventing prolapse or breaking and reducing the probability of complicated situations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

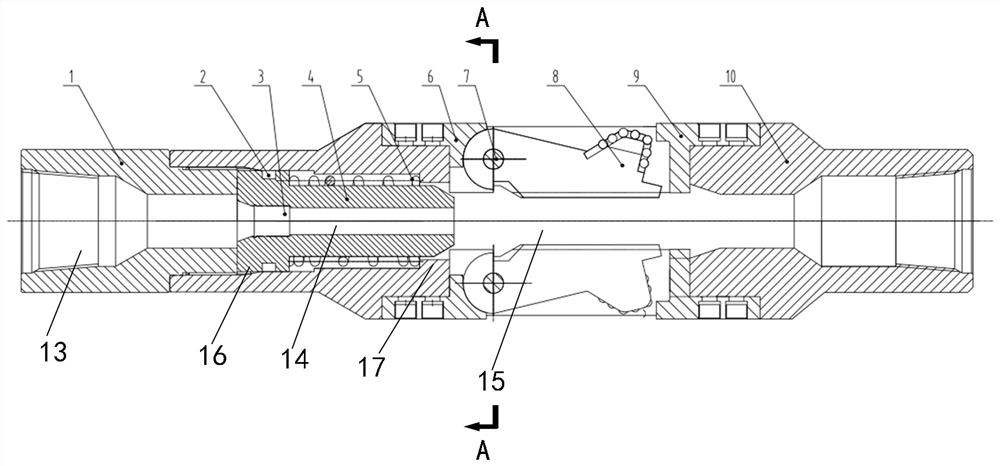

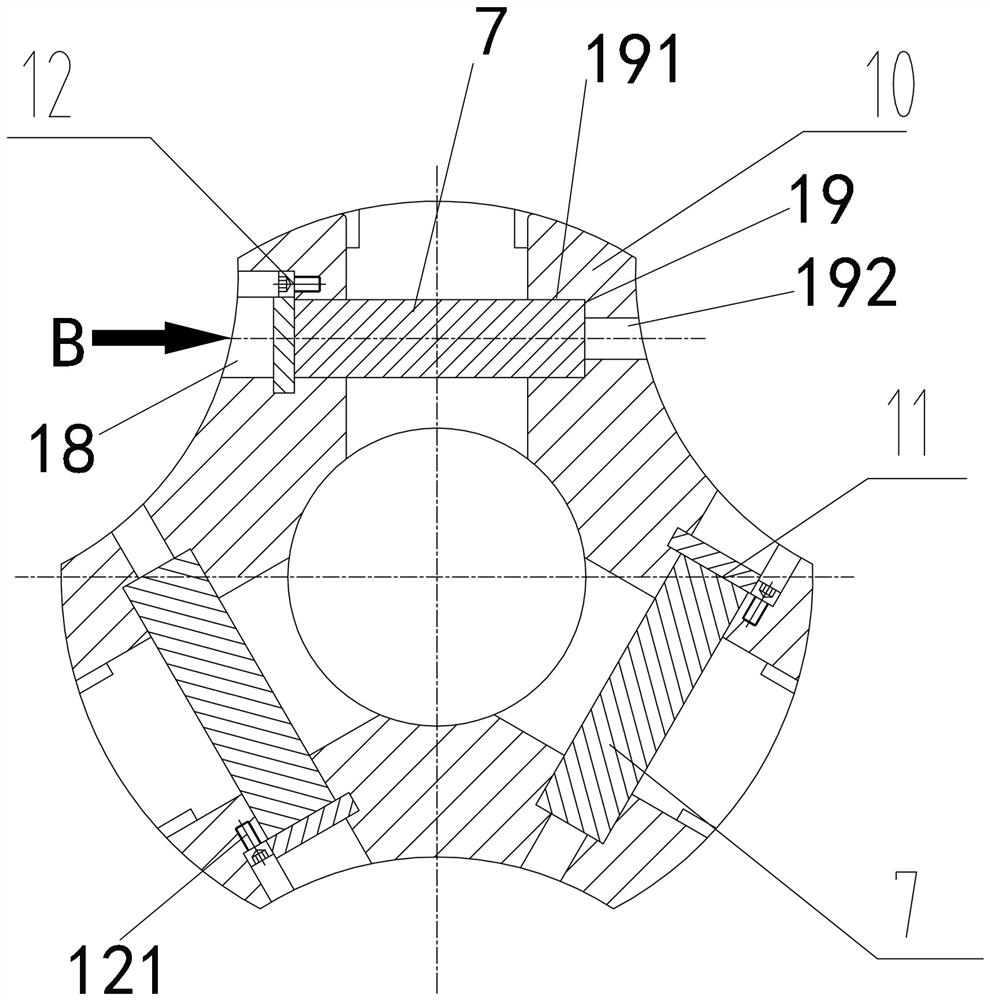

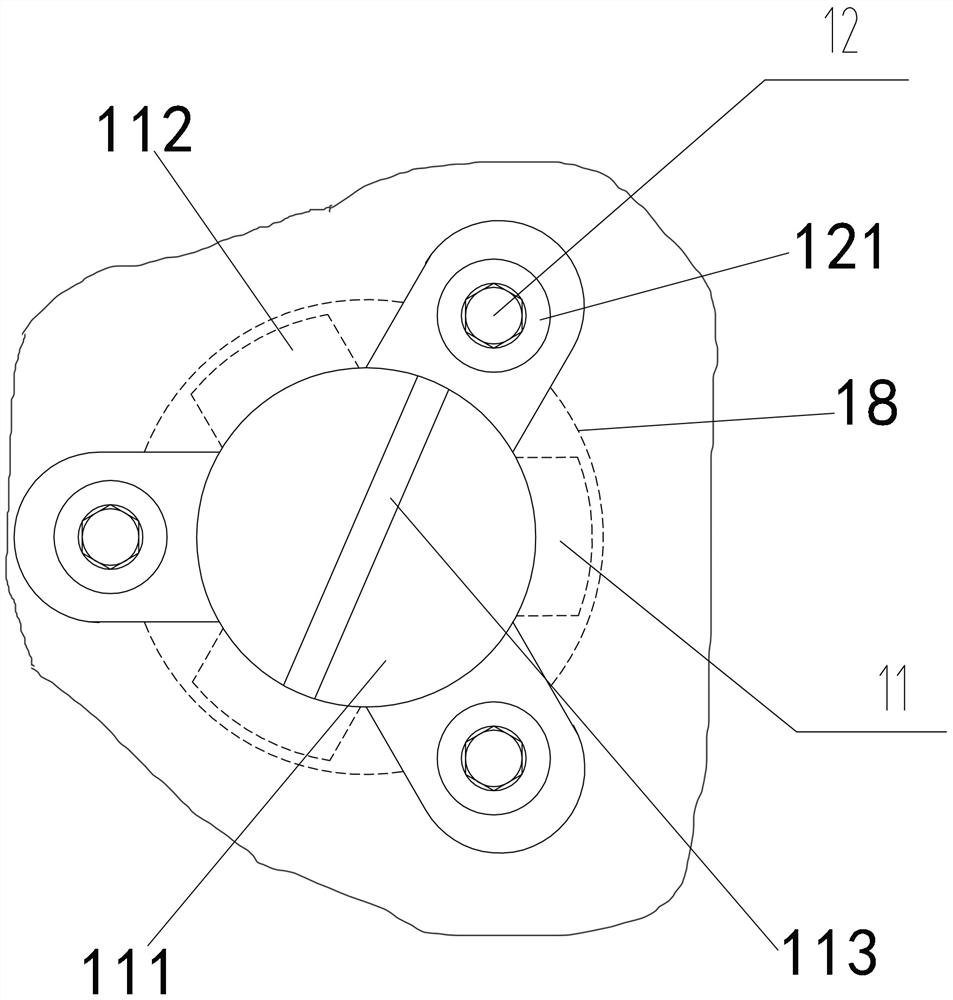

[0025] A post-drilling reamer with blades 8 pins 7 falling off, including an upper joint 1, a main body 10, a blade 8, a piston 4, a spring 5, a nozzle 3, one end of the main body 10 is connected with the upper joint 1, and the main body 10 is provided with The installation hole of the blade 8, the blade 8 is installed in the installation hole of the blade 8 through the pin 7, the upper joint 1 is provided with a first center hole 13, the body 10 is provided with a second center hole 15, the piston 4 is slidably sleeved in the second central hole 15, the left end face of the piston 4 is in contact with the right end face of the upper joint 1, the right end face of the upper joint 1 restricts the leftward sliding of the piston 4, and a third central hole 14 is arranged inside the piston 4. A central hole 13, a second central hole 15, and a third central hole 14 communicate with each other. The third central hole 14 is provided with a nozzle 3. The nozzle 3 is located at the left...

Embodiment 2

[0035] refer to figure 1, in the figure, the piston 4 and the spring 5 are placed in the body 10 together. When installing, use a special auxiliary tool to press the piston 4 down a certain distance, so that the lower groove of the piston 4 is exposed at the slot position of the blade 8, and then the blade 8 is installed. Insert into the main body 10, penetrate the pin shaft 7 to fix the blade 8 on the main body 10, install the support block 6 and the second limit block 9, and use screws to fix it. After the drilling fluid is injected into the tool, a pressure difference is generated at the position of the water hole of the piston 4, which pushes the piston 4 to go down, and the piston 4 pushes the blade 8 to expand outward at the same time. When the drilling tool rotates, the formation can be cut, and the steps are first built. When the three blades 8 are stretched to the maximum outer diameter under the action of the thrust of the piston 4, the steps are completed. At this t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com